- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

Wood remove defect cross cutting saw optimization machine

Model:MX100

Feeding length:300mm-∞

Feeding width:20-200mm

Feeding thickness:12-80mm

Power:12kw

Feeding length:300mm-∞

Feeding width:20-200mm

Feeding thickness:12-80mm

Power:12kw

Details

Spare Parts

Inquiry

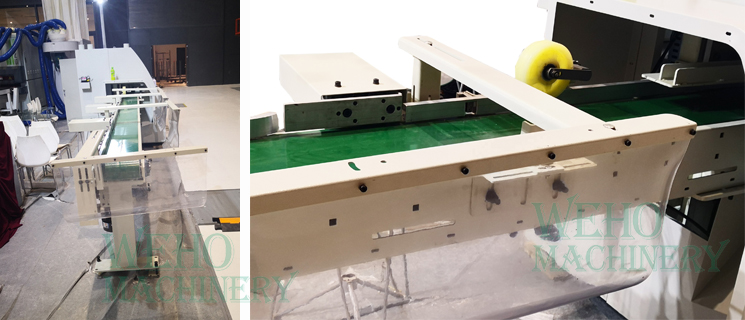

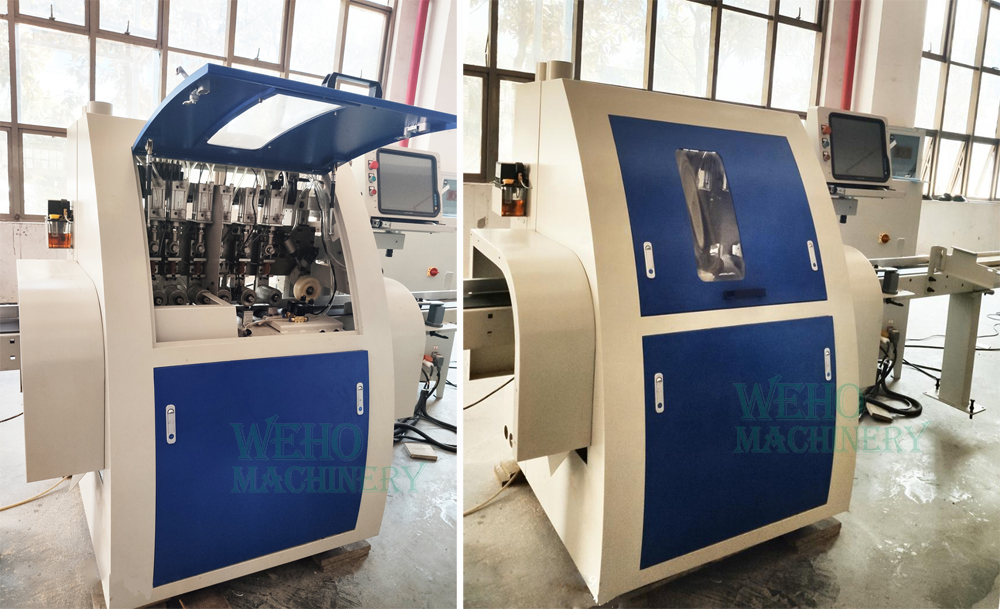

The optimal cross-cut saw is controlled by computer, which can form the best sawing plan for the production plan, cross-section the wood, and have the functions of analysis, optimization and statistics; it can greatly improve the wood yield and production efficiency.

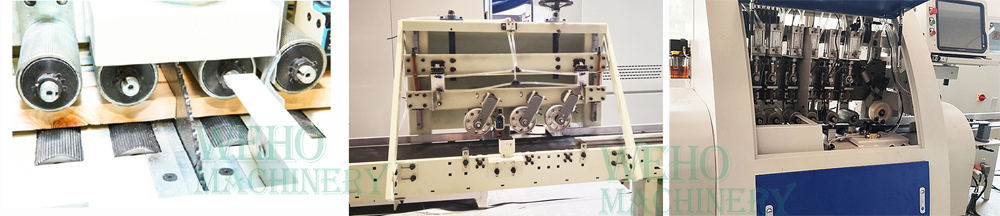

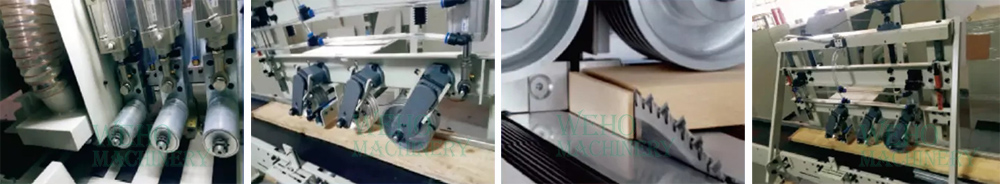

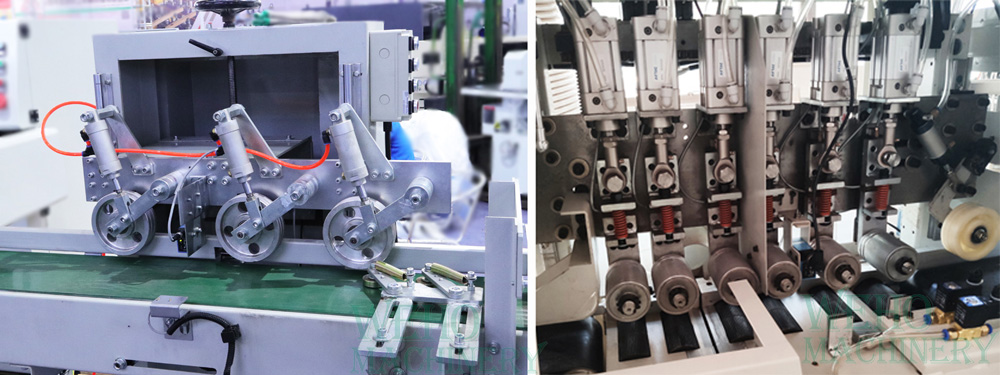

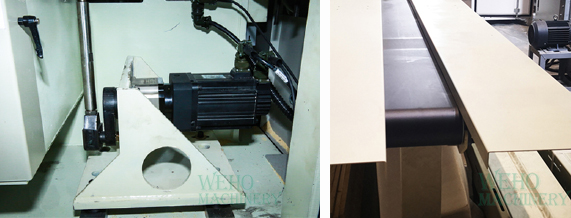

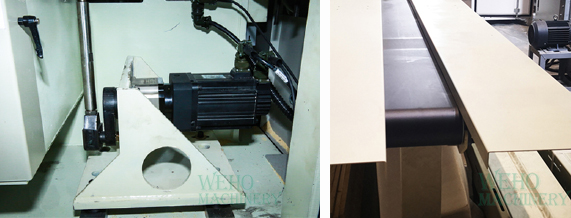

1. Both the lift saw system and the feed system have servo drives to ensure a smoother, more precise and efficient sawing process.

2.High-precision sensors and linear guides ensure high-speed feed of the machine

3.The working area is equipped with a closed protective cover, and the worker is far away from the sawing area and has high safety.

4.Save labor, increase production, and increase wood processing profit

5. Improve the yield, simple optimization, quantity statistics, servo lift saw, fast speed, strong stability

| Model | MX100 |

| Feeding length | 300mm-∞ |

| Feeding width | 20-200mm |

| Feeding thickness | 12-80mm |

| Fixed length at rear of saw | Min 80mm |

| Bend of the board | Max 10mm/m |

| Thickness tolerance | Max ±3mm |

| Cutting tolerance | ±1mm(≤1000mm) ±2mm(>1000mm) |

| Feed speed | 100m/min |

| Cutting cycle | 0.15s-0.3s |

| Wokring height | 900mm |

| Saw spindle motor | 4500rpm |

| Electric connected load | 12kw |

| Voltage | 380V/50HZ |

| Air consumption | 1200NL/min |

| Servive pressure | 8 bar |

| Diameter oa air consumption dusts | 12mm |

| Exhaust speed | 25m/s |

| Diameter of dust exhaust dusts | 120mm*2 |

Automate optimize wood cross-cutting machine ,Automatically supply oil to the main unit slider, which makes the lubrication effect of the slider better and prolongs the service life of the slider.

Wood cross-cutting machine for optimizing crosscut saw,Precision sawing mechanism, precise cutting, efficient and stable.

An automatic cross cutting saw makes it easy. Operators use a UV Crayon to mark defects in the material. The saw cuts around those defects and optimizes the clear material while cutting parts. Accuracy is an additional benefit you get from using an optimizing cross cut saw station. You won’t ever have to use a tape measure again and you will have repeatable accuracy at thousandths of an inch, meaning no more cutting inaccuracies, less material waste, and greater lumber savings.

Automate optimize wood cross-cutting machine,Stacking feeder to increase production efficiency.Optimizing crosscut saw,Powerful servo system, precise and efficient sawing method, superior stability.

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines. Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.