- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

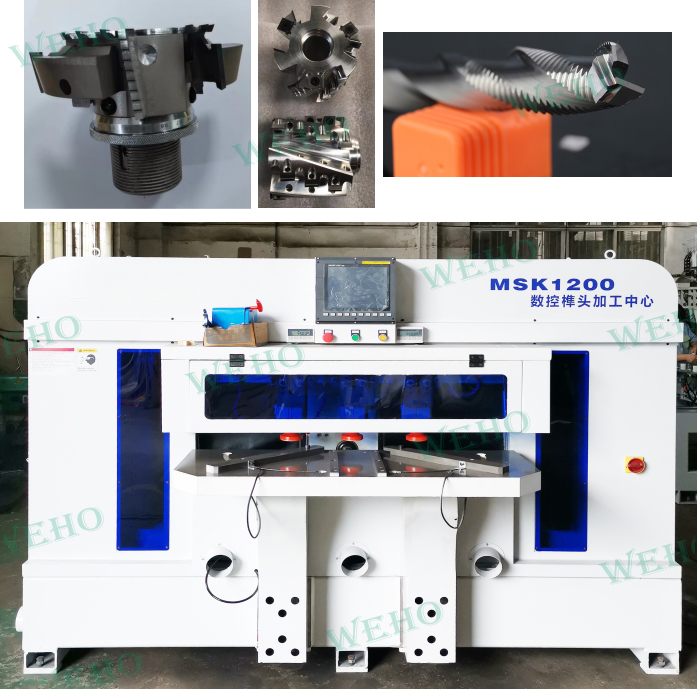

CNC Mortise and Tenon Processing Center

Model:MSK1200

Processing workpiece width: 0-120mm

Processing workpiece thickness: 0-80mm

Workbench size: 1200x450mm

Mortise blade shaft diameter: 30mm

Mortise and tenon cutter speed: 12000r/min

Mortise and tenon drill bit: 18000r/min

45°/135° mortise depth: 0 — 45 °

Material adjustment angle: 0°— 90°

Working pressure: 06-0.8Mpa

Mortise hole drilling chuck model: ER25

Total power: 13.1kw

Voltage: 380V

Rated current: 28A

Equipment size: 2450 * 1150 * 1700mm

Weight: 1800KG

Remote control mode: Internet

|

Processing workpiece width |

0-120mm |

|

0-80mm |

|

|

45°/135° mortise depth |

0 — 45 ° |

|

Material adjustment angle |

0°— 90° |

|

Working pressure |

06-0.8Mpa |

|

Mortise hole drilling chuck model |

ER25 |

|

Total power |

13.1kw |

|

Voltage |

380V |

|

Rated current |

28A |

|

Equipment size |

2450 x 1150 x 1700mm |

|

Weight |

1800KG |

|

Remote control mode |

Internet |

|

Electrical configuration: Low voltage electrical, Schneider System control: HUST Servo motor and drive: HUST |

|

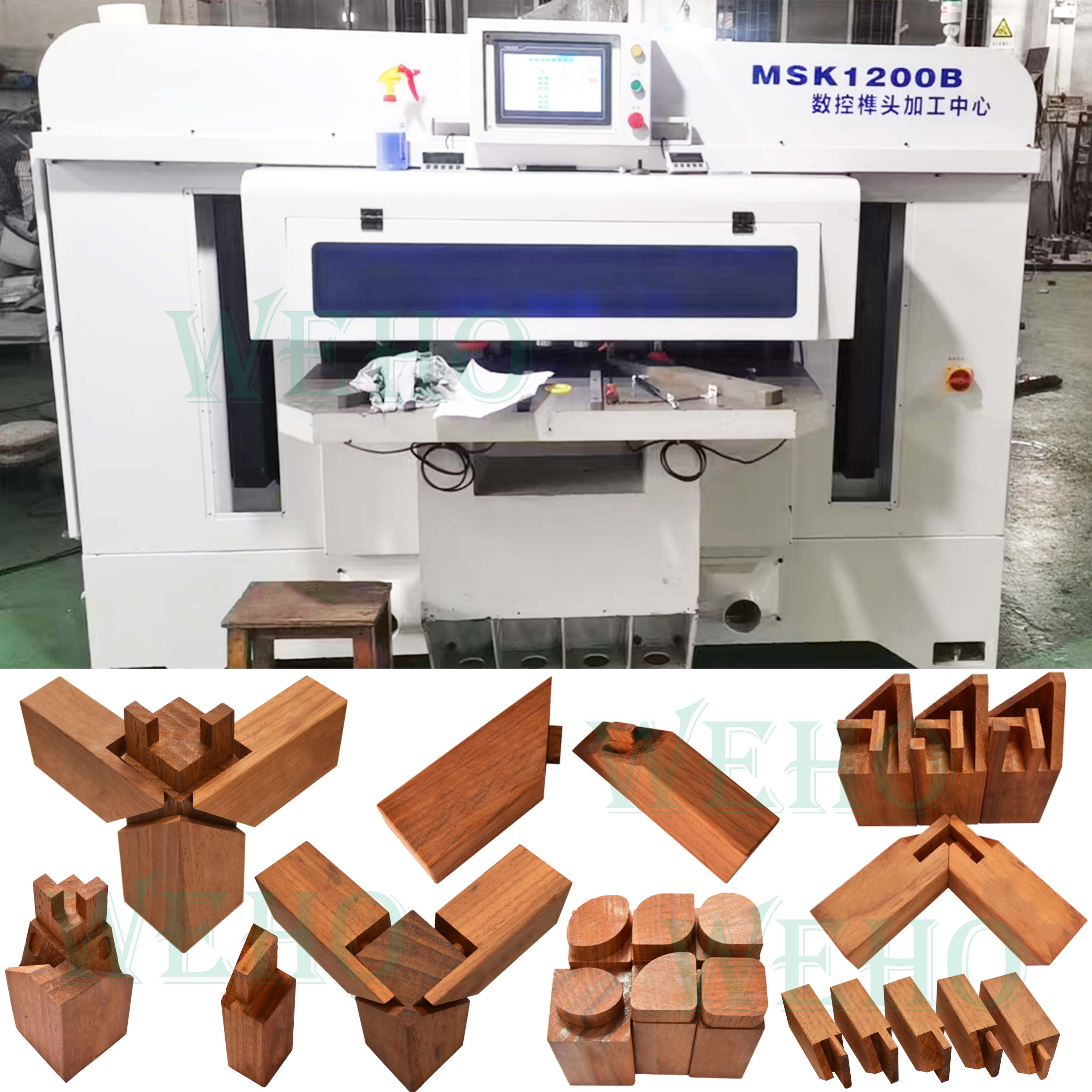

Processing case

Machine configuration

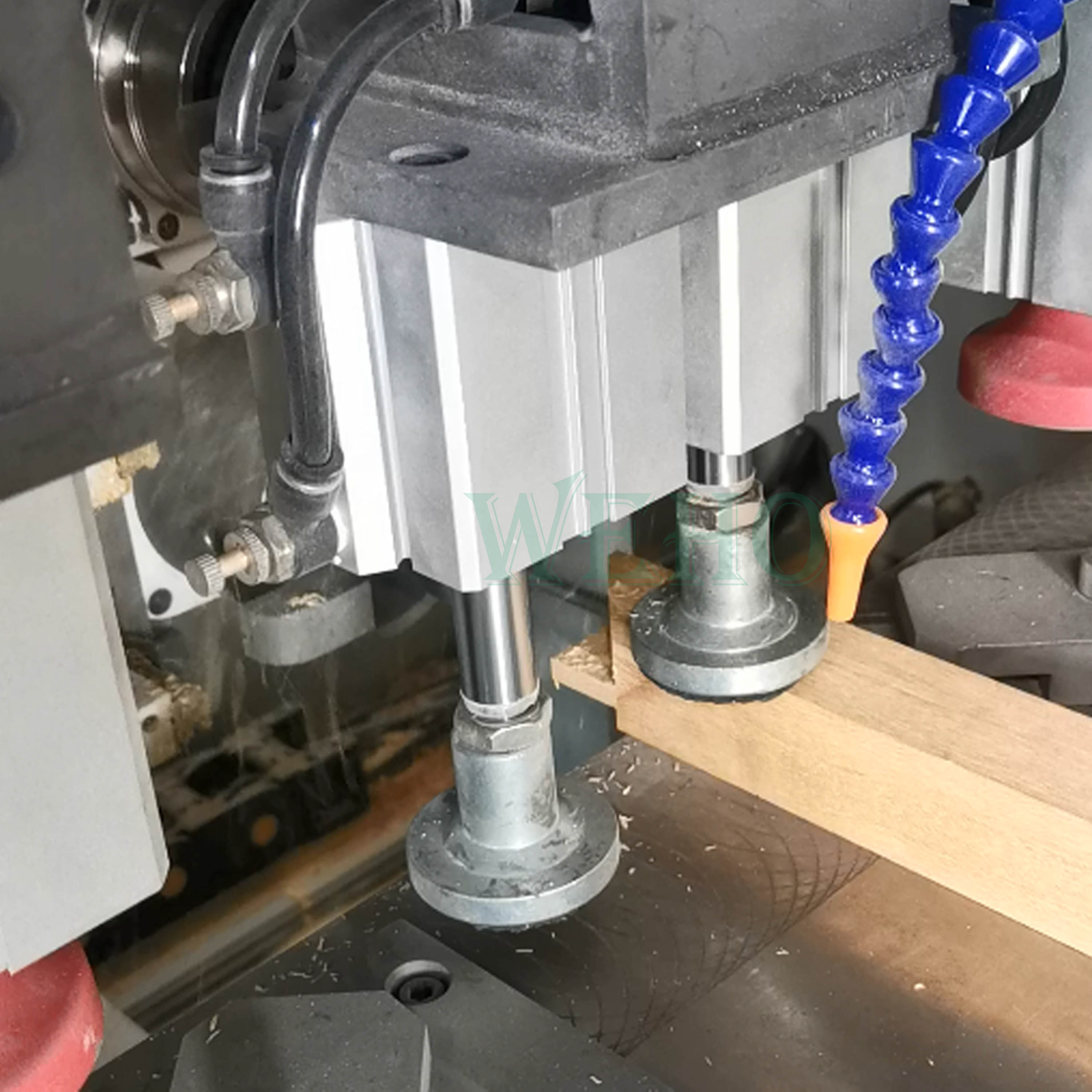

1.Famous domestic brand Kate Precision with dust cover imported guide rail (x-axis, z-axis, y-axis)

2.Famous domestic brand Kate Precision with dust cover imported slide seat (widened and lengthened)

3.Taiwan TBI imported silent 32010 screw (x-axis, z-axis)

4.Taiwan TBI imported silent 32010 nuts (x-axis, z-axis)

5.Taiwan imports the Yitu system

6.Taiwan Yitu comes with built-in servo, driver:

- X-axis 2.0KW without brake

- Y-axis 0.4KW without brake

- Z-axis 1.5KW brake (note: special warranty for 3 years)

7.Weidmuller Wiring Terminals Imported from Japan

8.Japanese imported and Xuan relay modules, relays

9.Imported NAICI bearings from Japan

10.Schneider electronic components imported from Germany

11.German imported Omron origin switch

12.Star Imported Sealing Rubber Pneumatic Components

13.Zhejiang Yiri Electromagnetic Valve Module

14.All of the above are covered by a 2-year warranty. (1. Natural disasters. 2. Failure to cooperate with our company's operators or equipment requirements. 3. Human error in operation. None of them are within the scope of maintenance.

Machine features

- Improvement in machining accuracy and efficiency:

1. The size accuracy of the tenon is ± 0.05mm (automatically adjusted by the system).

2. Dual station (stations and fixtures can be customized according to customer needs), high-speed continuous milling. While processing a set of workpieces

3. It handles the loading and unloading of workpieces, produces continuously, and processes over 20000 mortise and tenon slots (holes) every day (8 hours). Processing workpieces(500 mmX120 mm X50 mm) More than 480 tenons per hour, 70X20.

- Improved automation level:

The system operation is simple, just change the corresponding wood sample size on the human-machine interface, and the requirements for operators are very low,

Saved customers from investing in operator training. - Improved service life:

1.Computer controlled automatic oil pump YET-B2P2 (system time limit). Divided into three groups (each with five ports) with 15 oil circuits. Use the Foshan River Valley automobile specific quantitative oil separator to lubricate each slider, screw nut, and bed surface rail.

2.Just insist on daily maintenance and timely refueling (rail oil or 45-150 oil) to extend the service life of Taiwan imported rails and ball screws by 7-10 years or more.

3.The body and workbench are uniformly annealed, with a shelf life of over one year, rough machining, and precision machining on the machining center. Ensure the stability and service life of the equipment.

4. The repeated positioning accuracy of Y and Z is 0.01-0.03 mm.

How to buy

1. Contact WEHO sales and provide your requirents to get best solutions

2. Order confirmed, get invoice, contract from WEHO.

3. Normally, producton started against TT by 30% deposit.

4. After one week, WEHO sales inform you production state and delivery date.

5. Order finished, WEHO sales send you photos, videos and spare parts for confirmation.

6. Book shipping order, delivery the machine to your port.

How to do if I can not operate

When you get the machine, if you have operation problem, we will make video meeting to teach you. If video teaching can not solve, our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for weho machines, including find problems, send spart parts, and teach you to replace the parts.

Service contacting

Before buying, choose suitable model contact Whatsapp 008613378477841. After buying, technical supporting contact 008613326792205

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.