- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

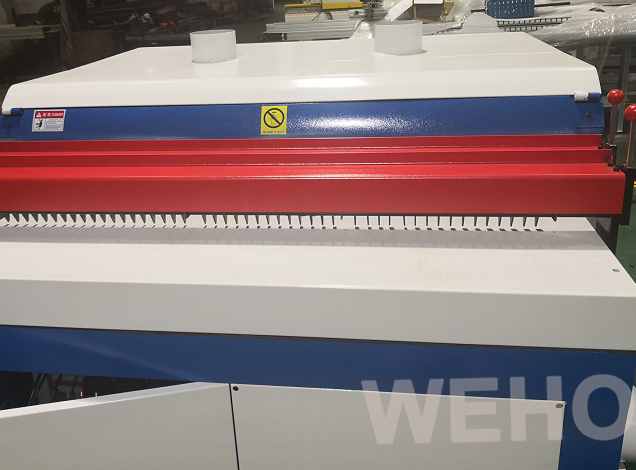

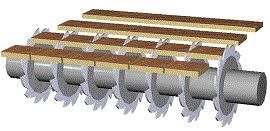

Wood multi blade wood slitter table saw machine rip saw for plywood

Model:MJ1300

Working Width (mm):200-1220

Working Thickness (mm):5-30

Working minimum length (mm):550

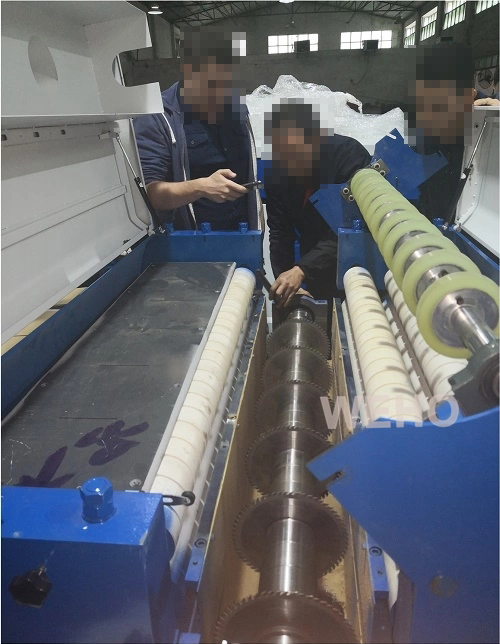

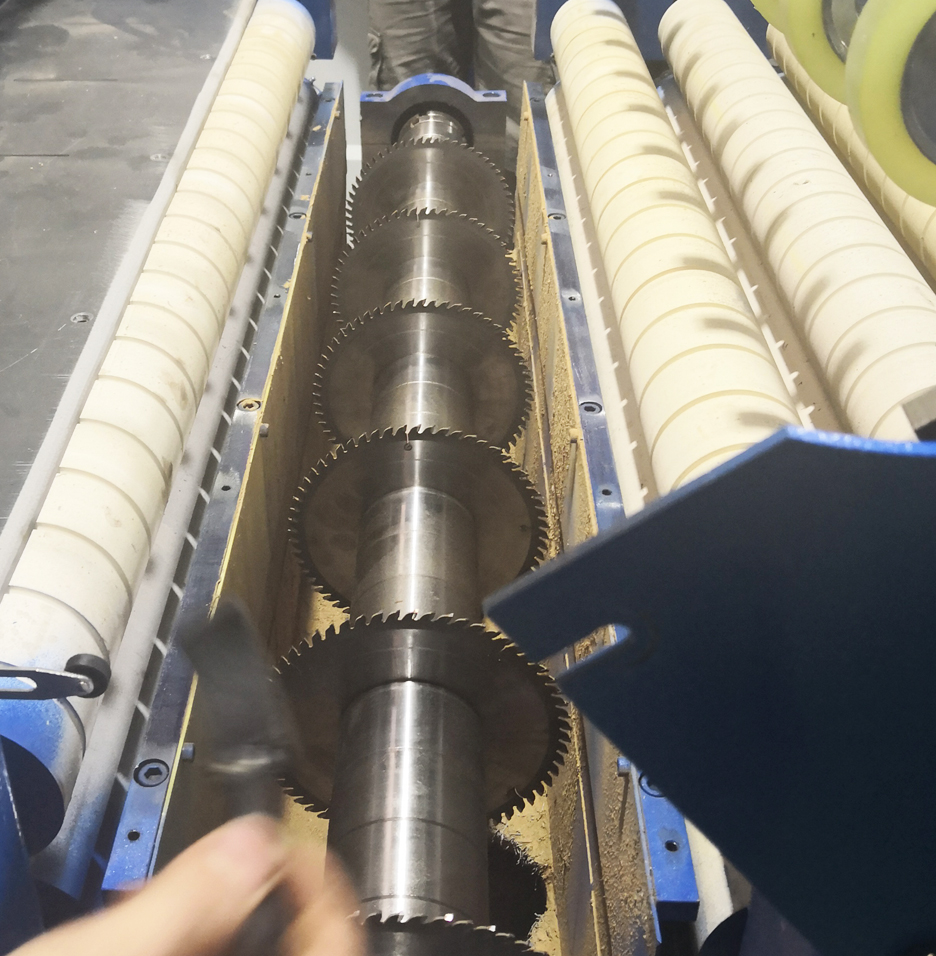

Spindle diameter (mm):74

Diameter of saw blade (mm):205

multi blade saw machine safe and simple operation, saw shaft has precise machining, make the whole machine work more stable and smooth, ensure the sheet after cutting are smoothness and precise straightness.

|

Model

|

Max:1220 Min:200

|

|

Working Width (mm)

|

Max:1300 Min:200

|

|

Working Thickness (mm)

|

Max:30 Min:5

|

|

Working minimum length (mm)

|

550

|

|

Spindle diameter (mm)

|

74

|

|

Spindle speed (r/min)

|

2600

|

|

Diameter of saw blade (mm)

|

205

|

|

Spindle motor power (kw)

|

11 (can be increased to 22)

|

|

Feeding motor power (KW)

|

1.5 (capacity increasing to 3)

|

|

Total installed motor power (KW)

|

12.5(capacity increasing to 25)

|

|

Feeding speed (m/min)

|

0-12

|

|

Number of feeding rod sets/bars

|

6/12

|

|

Outer diameter of chip removal tube (mm)

|

150

|

|

Dimensions (mm)

|

2200 x 1800 x 1250

|

|

Machine weight (kg)

|

2200

|

Multi blade saw machine Main Features:

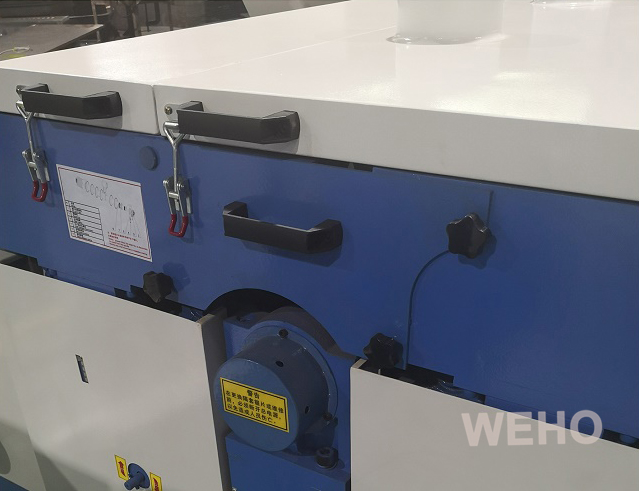

1.Humanized design of working platform, easy and smooth feeding.

2.It can process long, broken, thin, thick and other types of plates.

3.The worktable is equipped with front and rear active feed rollers to facilitate feeding and reduce work intensity wood multi blade saw machine.

4.Fast speed, stable feeding, high spindle speed, smooth saw blade, long service life.

5.Fully enclosed safety guard, safe and environmentally friendly,dust protection and environmental protection device .

The process of cutting wood with automatic feeding, multi-saw cutting, continuous discharging, its production efficiency is very high floor multi blade saw.

The automatic multi rip saw compose of mechanical automatic feeding, front and rear pushing material cylinder parts, height detecting parts, automatic pressing parts, saw blade adjustment parts, PLC control system and liquid crystal touch screen are optional.

Cast Iron Reciprocating Machine automatic panel saw cutter,The heavy duty rigid cast iron frame supports the work table and helps dampen vibration and ensures years of dependable service.

Applicable scope: solid wood composite floor, reinforced composite floor, board furniture,environmental protection sound-absorbing board, wooden packing box, integrated wood, picture frame, bed row framework/board once saw into many equal or different specifications of material processing, and can be cut in the material slot. Precision saw shaft to ensure that the saw out of the plate finish and straightness more accurate.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.