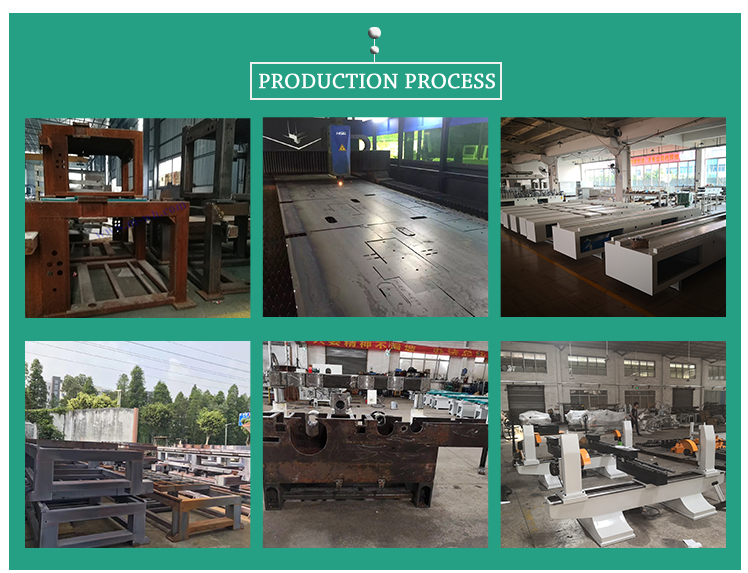

- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

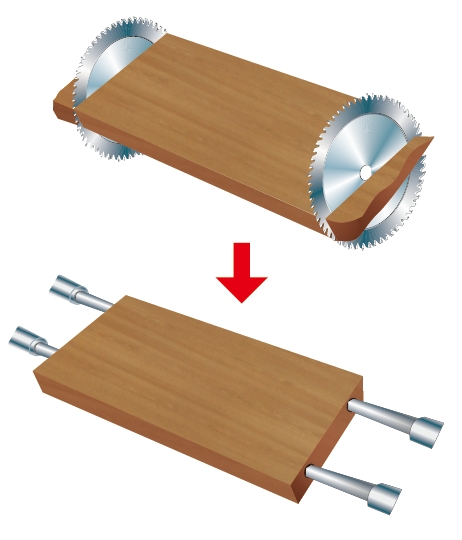

Wood circular saw double end shaper cutting machine

Processing length:300-1800

Vertical shaft diameter:ϕ30

Saw shaft diameter:ϕ25.4

processing length:300-1800

Feeding speed:5-15m/min

Axis speed:2840rpm

|

Produce name

|

door cutting machine

|

|

Model

|

MXJ1806

|

|

Processing length

|

300-1800

|

|

Feeding speed

|

5-15m/min

|

|

Saw blade vertical axis

|

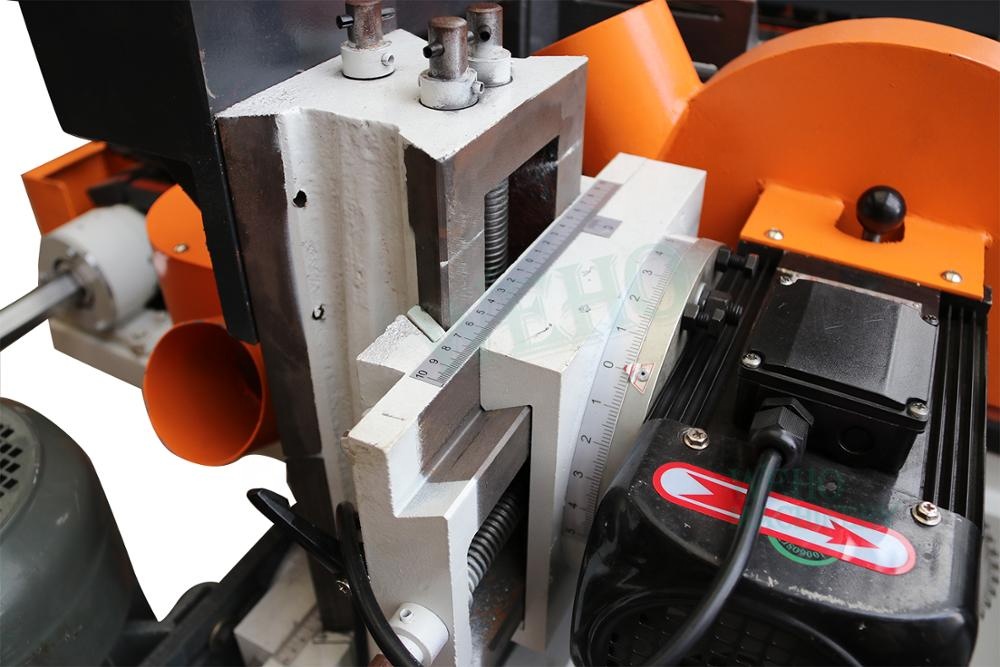

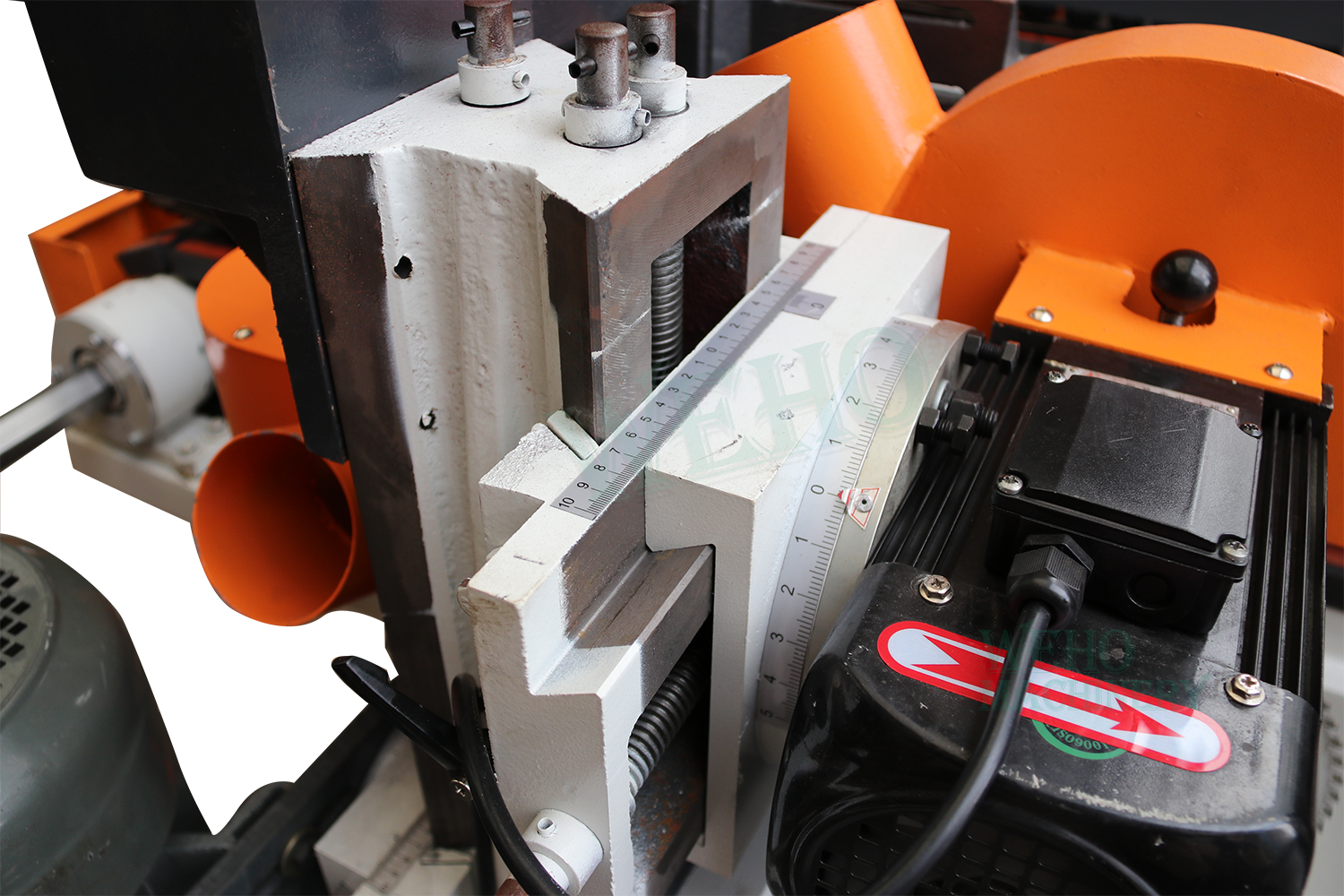

Tilt angle

|

|

Axis speed

|

2840rpm

|

|

Vertical shaft speed

|

6000rpm

|

|

Vertical shaft diameter

|

ϕ30

|

|

Saw shaft diameter

|

ϕ25.4

|

|

Install X power

|

20kw

|

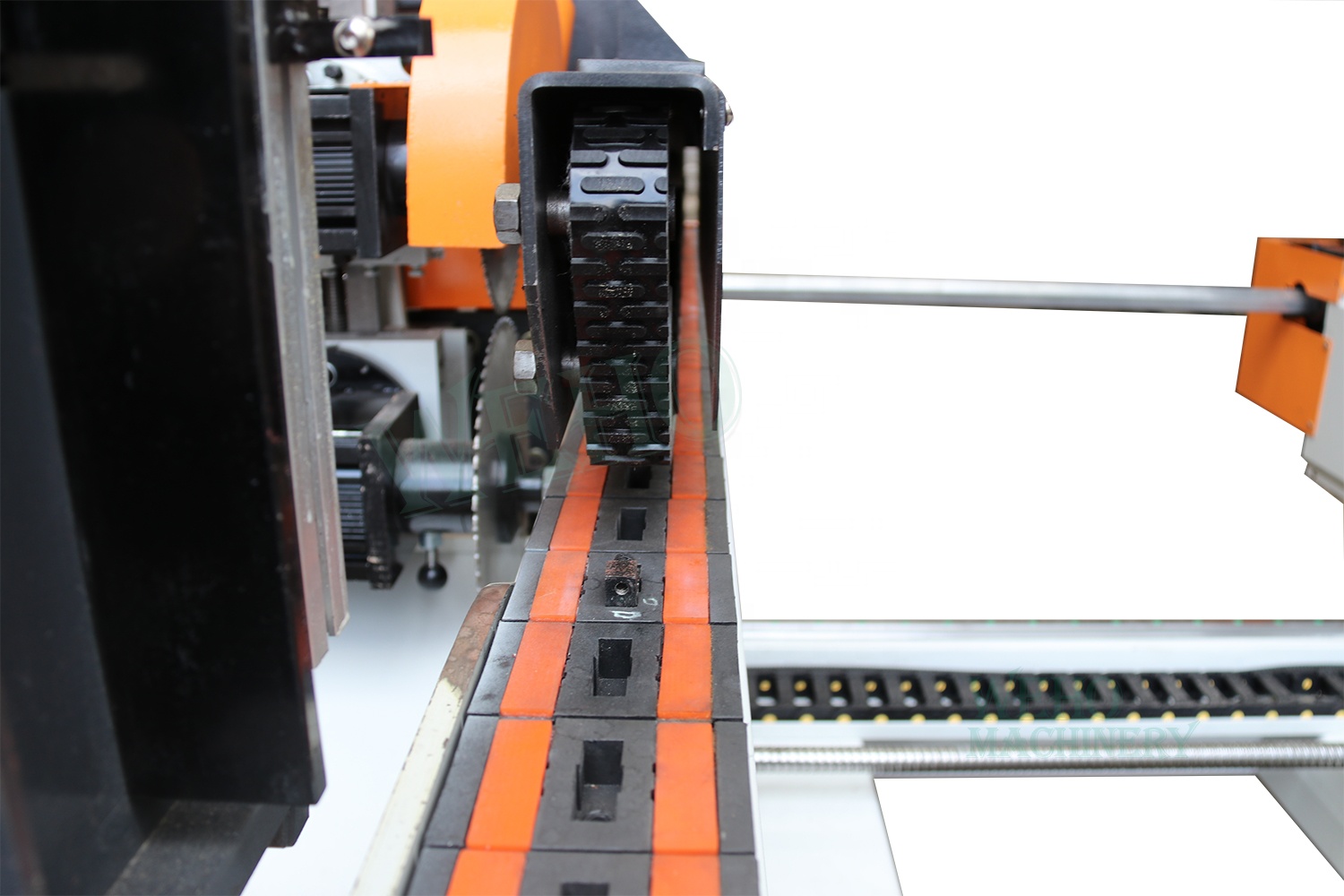

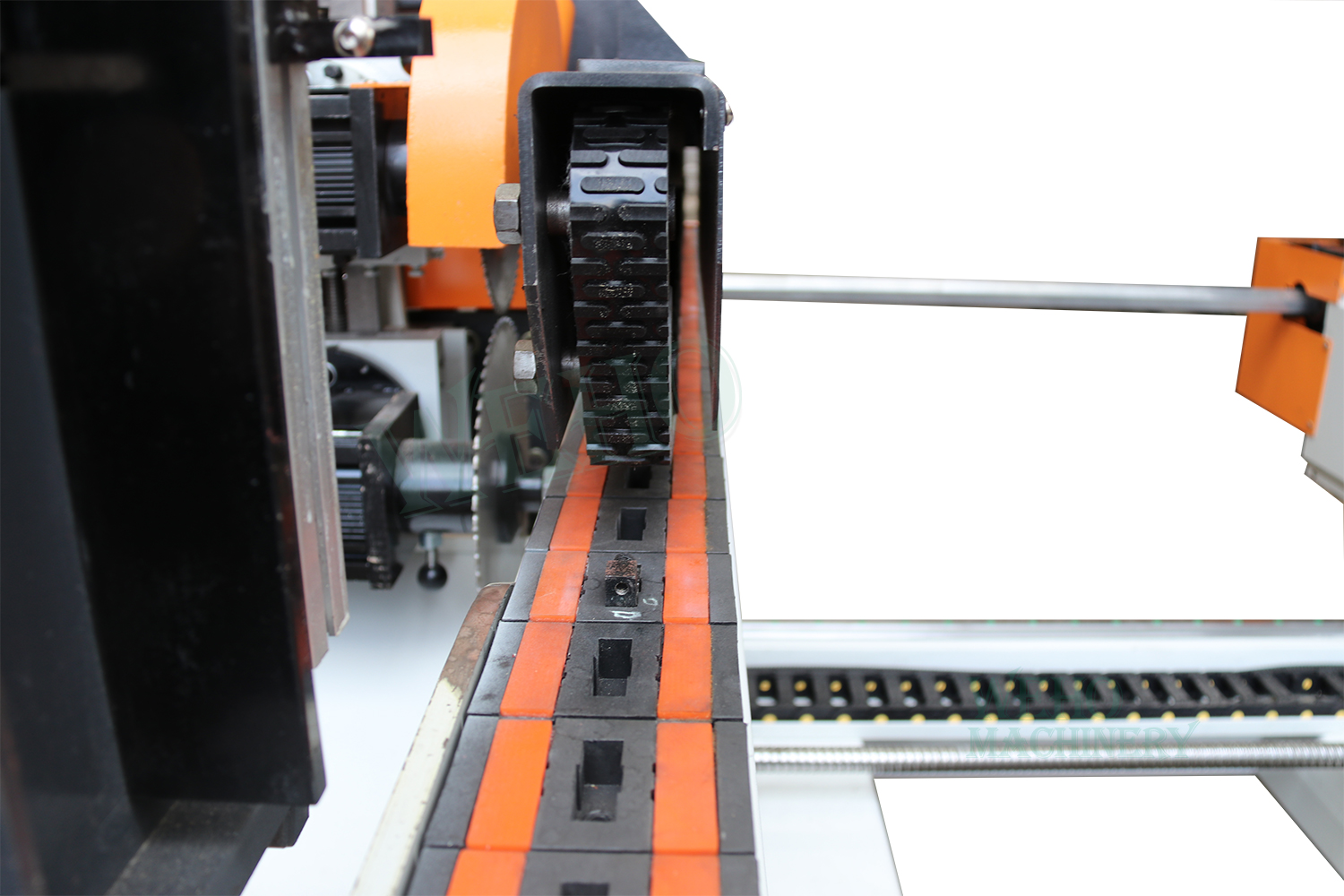

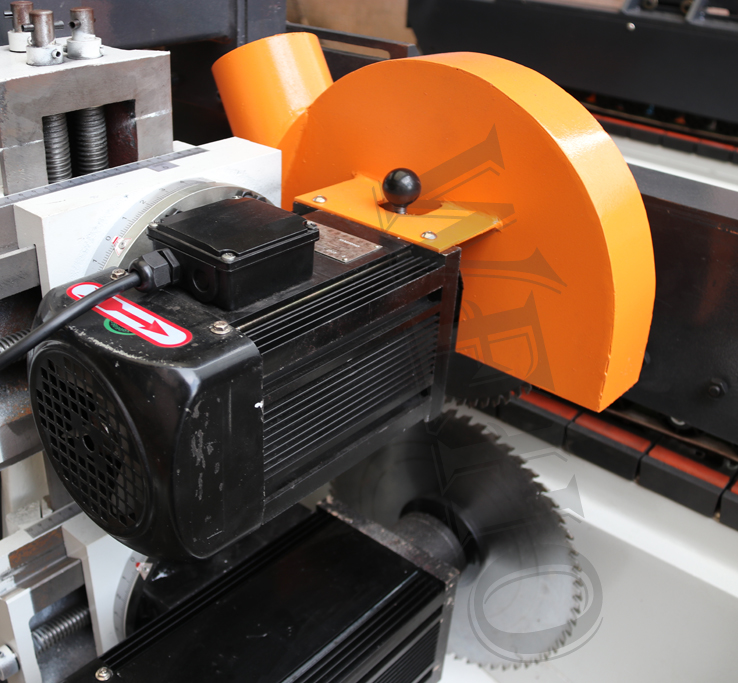

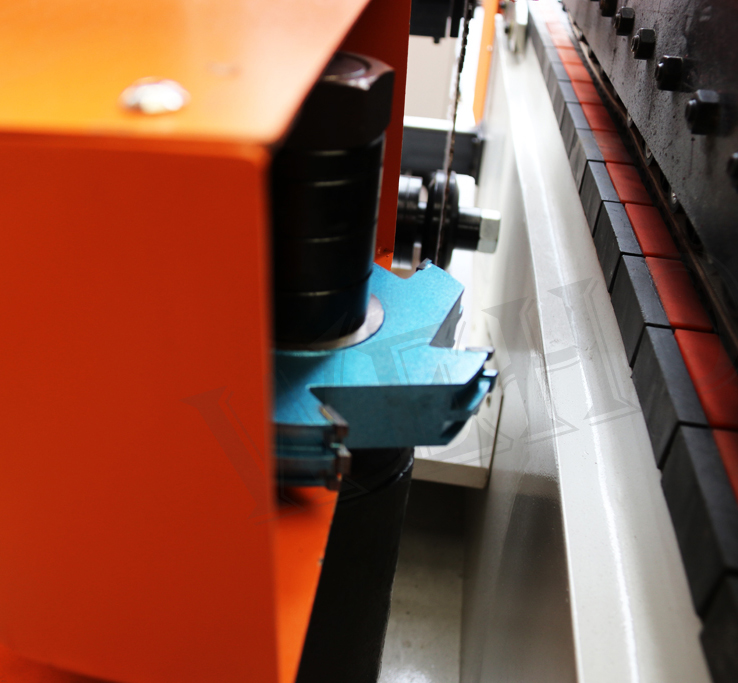

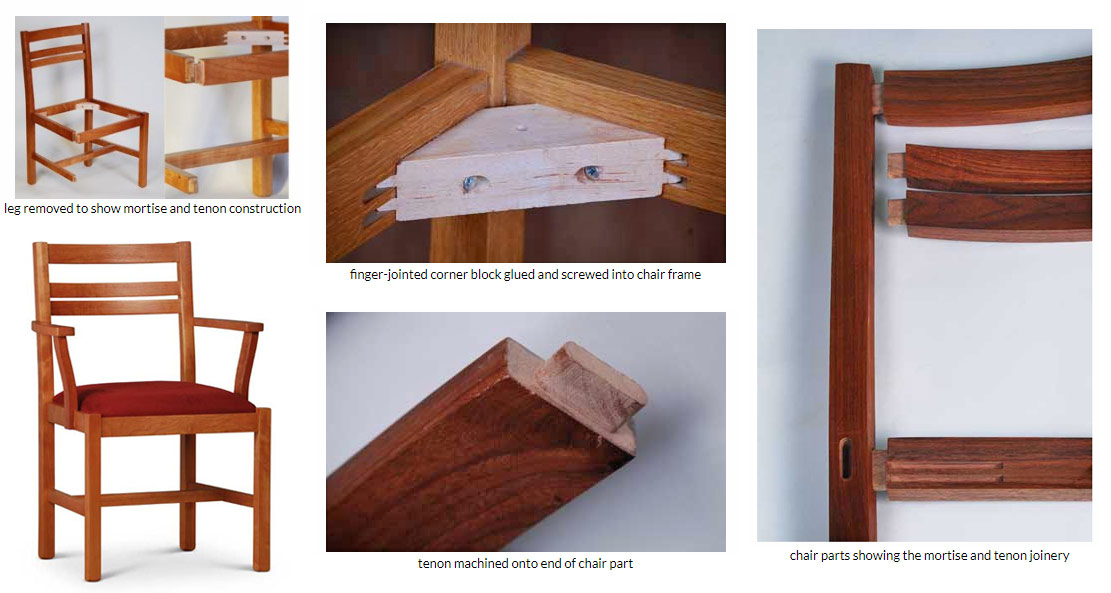

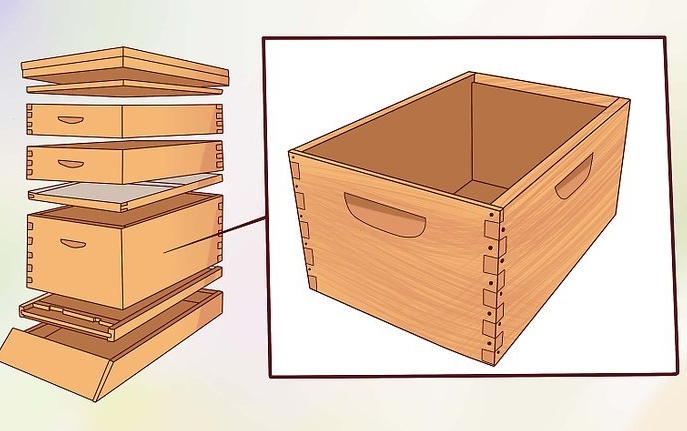

Double-end trim saw are wood end processing,It can easily deal with longitudinal and transverse profiling in the through feed. The work pieces are conveyed past the various processing units on a chain conveyor. work pieces are held by top pressure.In double end trim cutting process, the work pieces are held by top pressure and pressed onto the reference surface, the chain conveyor. As a result the work pieces are always processed with the visible side downward.

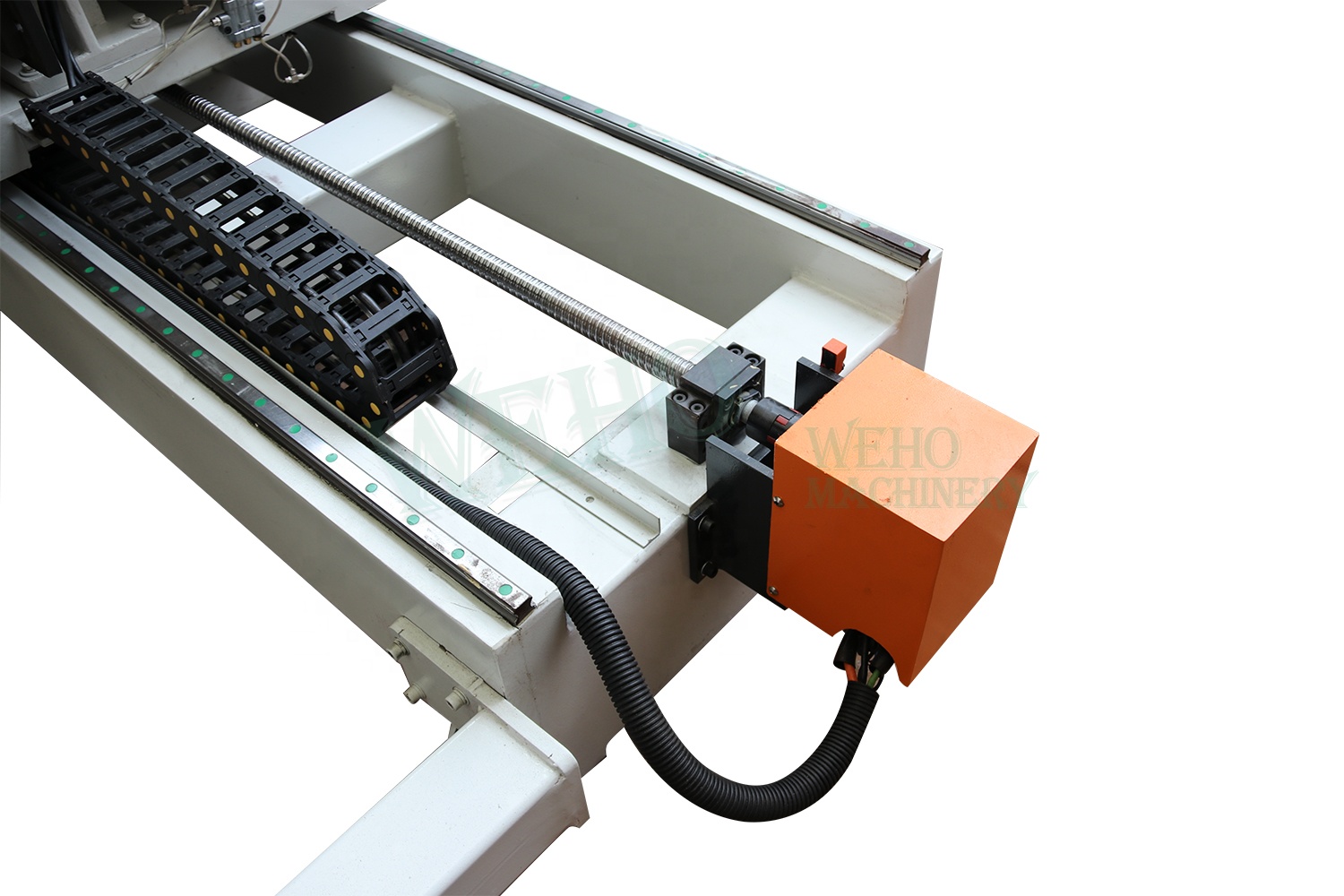

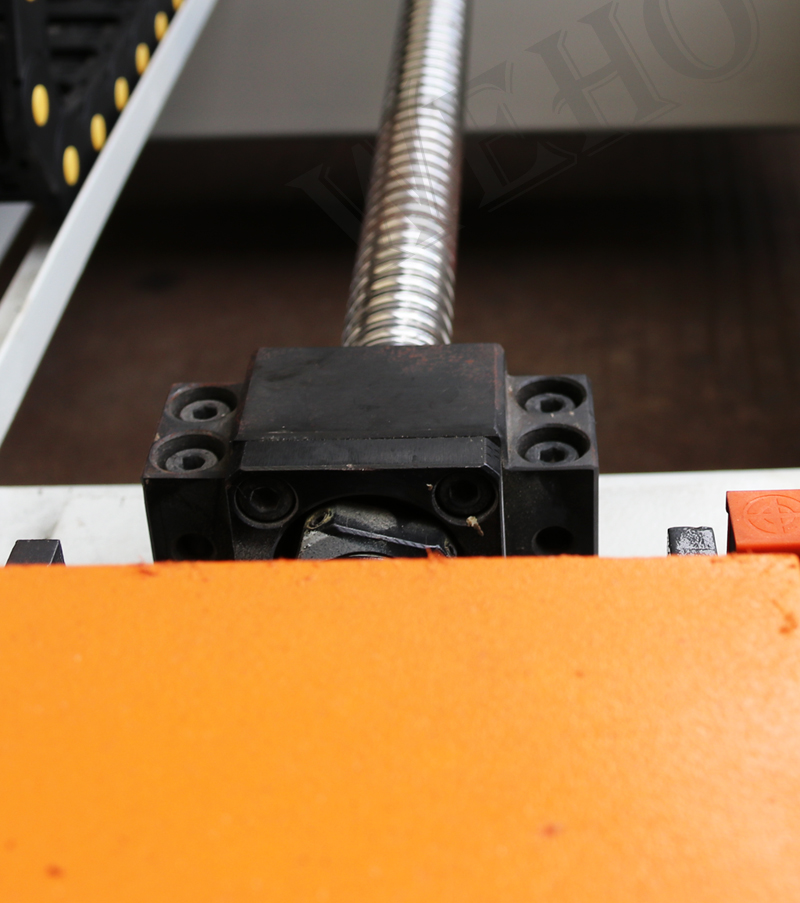

Four side cutting machine for door linear guide rail made from Taiwan ensure end saw moves smooth and accuracy.Track conveyor with fast feeding speed from 8-15 meter per minutes, ensure high efficient end saw cutting or shaper.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.