- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

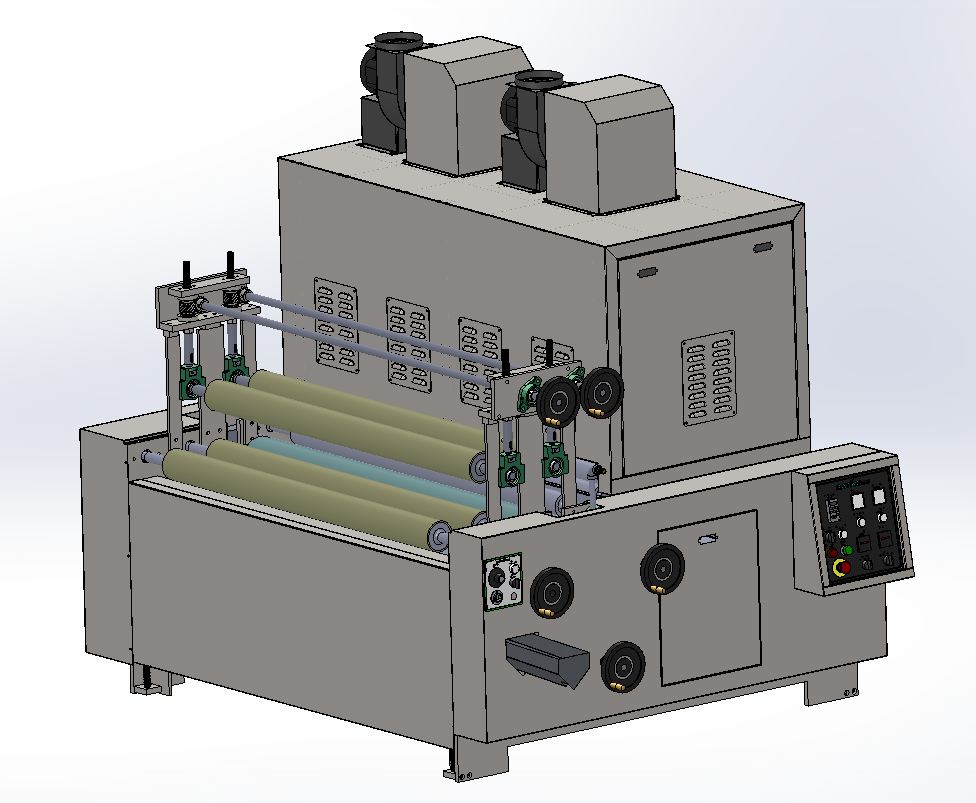

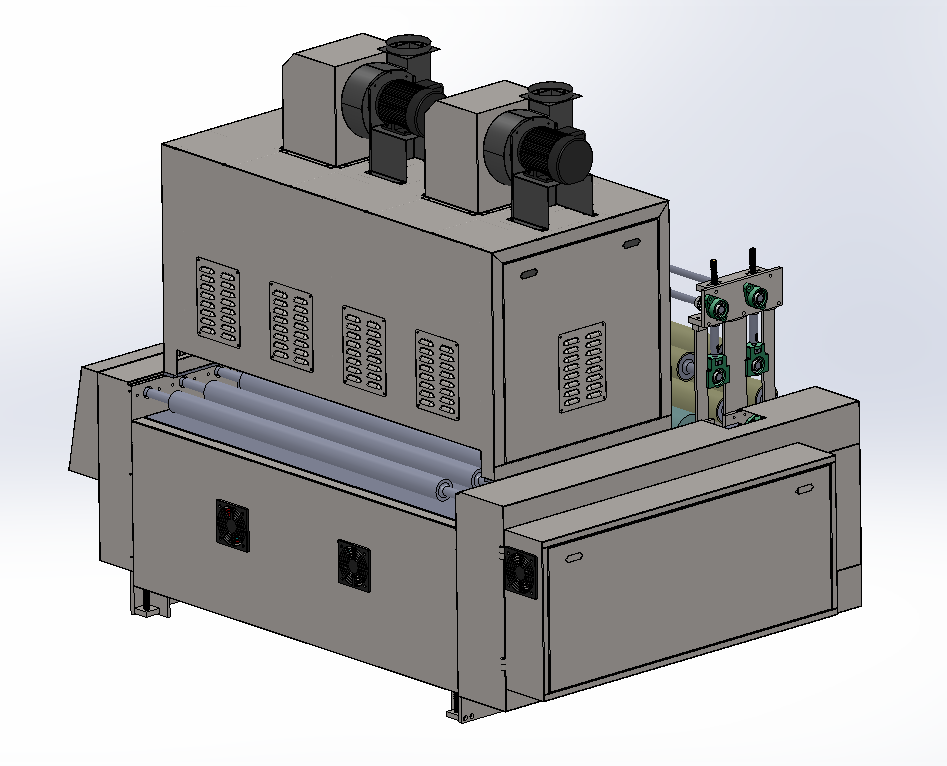

Uv coating machine for wood furniture cabinet MDF melamine panel

- Processing length range (max, min):Min300mm

Processing width range (max, min):Max600mm

Machining thickness range (max, min):3-80mm

Roller spec:100mm*640mm,

Gluing roller Dia, qty:150mm*640mm,*1

Lamp wattage:5.6KW

Weight (KG):700 KG

Power (kW):16

Details

Spare Parts

Inquiry

The machine is suitable for finishing paint, panel furniture, parquet, flat door, handicraft, bamboo curtain and special-shaped material. The thickness of the paint curtain is easy to adjust and accurate. It can be adjusted to 0.06mm if it is small. The adjustment of coating thickness is very accurate to ensure the uniformity of the whole coating surface.

|

Model

|

600

|

900

|

1300

|

|

Processing length range (max, min)

|

Min300mm

|

Min300mm

|

Min300mm

|

|

Processing width range (max, min)

|

Max600mm

|

Max900mm

|

Max1300mm

|

|

Machining thickness range (max, min)

|

3-80mm

|

3-80mm

|

3-80mm

|

|

Roller spec

|

φ100mm*640mm,

|

φ100mm*940mm,

|

φ100mm*1340mm,

|

|

Gluing roller Dia, qty

|

φ150mm*640mm,*1

|

φ150mm*940mm,*1

|

φ150mm*1340mm,*1

|

|

Feed speed

|

0-20min/m

|

0-20min/m

|

0-20min/m

|

|

Feed power

|

0.75KW

|

0.75KW

|

0.75KW

|

|

Lamp wattage

|

5.6KW

|

8KW

|

11KW

|

|

temperature range

|

60-100°

|

60-100°

|

60-100°

|

|

Cot hardness

|

35-40°

|

35-40°

|

35-40°

|

|

Installed power of the whole machine

|

16KW

|

20KW

|

24.5KW

|

|

Total weight

|

700KG

|

800KG

|

1000KG

|

|

Package size

|

1600*1600*1700MM

|

1600*1900*1700MM

|

1600*2300*1700MM

|

This machine is used for applying UV curing paints on the back of amboo floors, calcium silicate boards, and other boards. Integrates single-roll painting with dual-lamp UV drying, mplementing simultaneous painting and drying.Helps boards effectively prevent water from permeating to the boards through the back after being processed by the machine, providing good anti-deformation result.

The uv coating machine for funiture application viscosity, construction temperature, gap size of shower head and transmission speed will affect the thickness of coating.When adjusting, it should be considered comprehensively.

The UV coating machine is equipped with a coating circulation device, which can recycle the coating and eliminate the waste of coating. The conveyor belt is made of high quality resin, solvent resistant and easy to clean. The conveyor belt and pump are regulated by frequency converter. Various paint characteristics are suitable.

The UV coating machine is equipped with a coating circulation device, which can recycle the coating and eliminate the waste of coating. The conveyor belt is made of high quality resin, solvent resistant and easy to clean. The conveyor belt and pump are regulated by frequency converter. Various paint characteristics are suitable.

This desktop uv coating machine adopts single roll coating and double lamp UV drying, which can finish painting and drying at the same time,and suitable for UV coating on the back of bamboo wood floor, silicon calcium board, etc.

Our Advantages

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines.Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

Uv Coating Machine

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.