- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

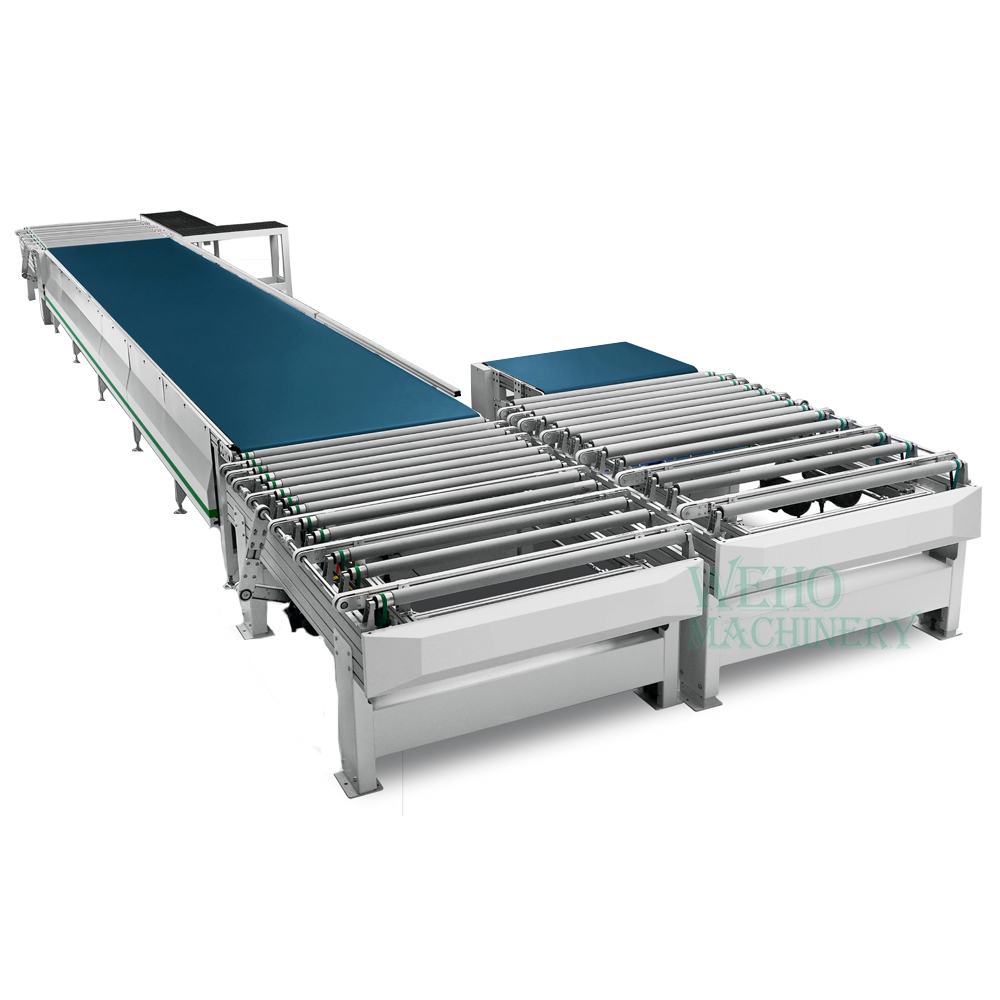

Power idler belt and roller return conveyor line system for edgebander automated edge processing

Voltage:380

Power:9kw

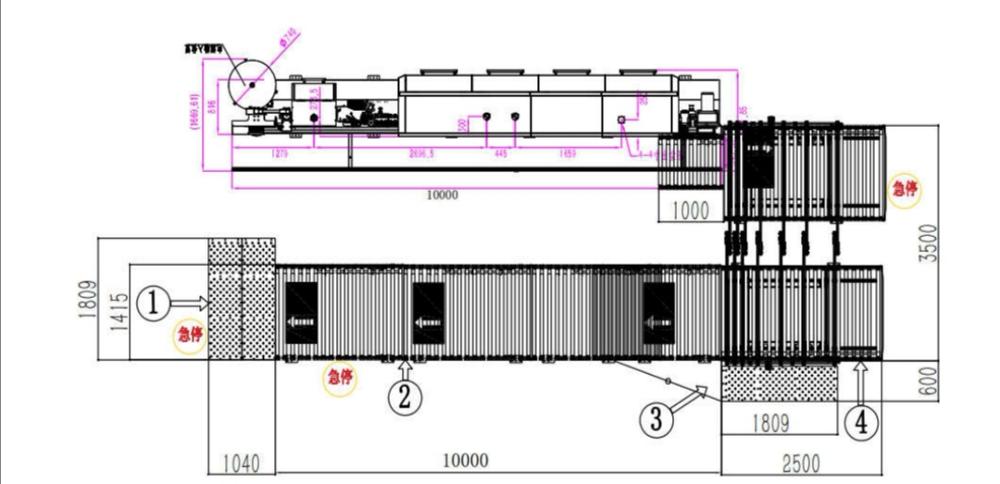

Dimension(L*W*H):6500mmx3000mmx1500mm

In large furniture manufacturers, many sets of edge banding machines can be connected for production; two (or four) edge banding machines can be used for left and right connecting mode, multiple ways such as same direction rotation line. Common full-automatic edge banding machines are equipped with auxiliary facilities such as translation power roller table, power inclined roller table, square feeding unit, etc. to realize automatic connecting and processing of edge banding machines.

| Name | Automatic belt conveyor |

| Processing objects | Furniture factory wood sheet panel board |

| Roller | blend rubber plastic |

| Working size | Min:250*250mm |

| Speed | inveter control |

| Warranty | 1 year |

| Length | customized |

| advantage | save labor, high efficiency |

Return conveyor for Edge banding line that can be matched in the intelligent full-automatic production line of customized furniture.

Automatic customized furniture intelligent production line by Roller Return conveyor.For the plates return of the edge banding machine, combined of the roller and the translation belt.Return conveyor mainly includes: discharge A part, rotation B part, conveying roller C part, end translation roller D part, air flotation table E part, total 5 parts. No operator required at the end of the equipment.

Return conveyor Fully automatic line is available, with six side drilling machine, CNC nesting machine connecting, and automatic sorting system, can build customized furniture intelligent production line.

This Belt and Roller Return conveyor for edgebander automated edge processing is total customized, according to your work pieces size, material and matching machine (edge banding machines or other machines) size, working speed, functions etc. We make design and solution according to your information, cost calculated after you confirm design.

Economical design ideal for the smaller operation or standardized parts.In-feed hold down to insure complete part acceptance.Durable, heavy duty steel construction for Return conveyorAdjustable in-feed to match most any machine.Adjustable jack legs to match most any machine height.Close belt spacing to aid in the transfer of smaller parts.Available in several sizes to fit your application.

Economical design ideal for the smaller operation or standardized parts.In-feed hold down to insure complete part acceptance.Durable, heavy duty steel construction for Return conveyorAdjustable in-feed to match most any machine.Adjustable jack legs to match most any machine height.Close belt spacing to aid in the transfer of smaller parts.Available in several sizes to fit your application.

A workpiece return will benefit any company operating an edge banding machine in their production.You can find the right automation solution for your edge banding machine here.Related products with Return conveyor for edgebander.

Workpiece returns for automated edge processing,From the entry-level variant of the workpiece return to fully automated edge circulation,Better machine utilization and significantly reduced downtime,Wide variety of workpieces,High profitability and short amortization times,Increased quality,Ergonomic handling,Simple operation,Flexible,organization of personnel.

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines. Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

Return Conveyor

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.