- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

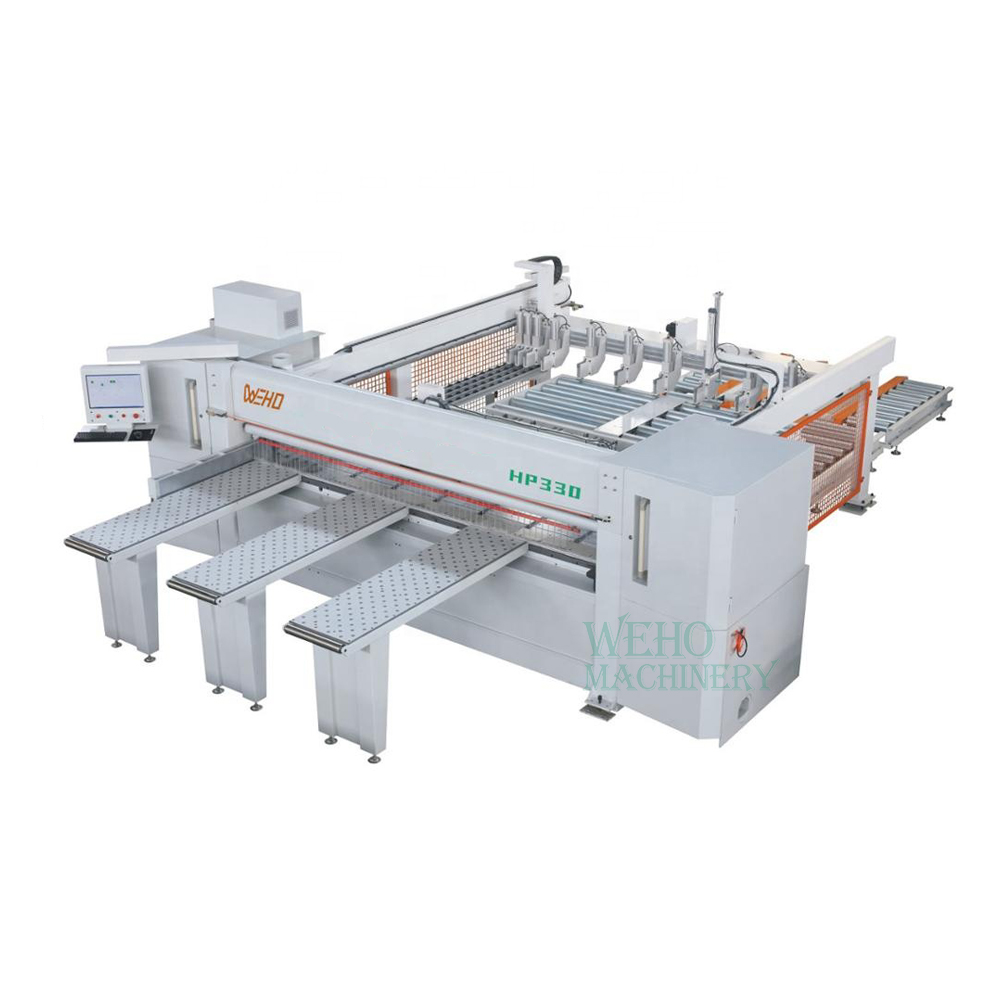

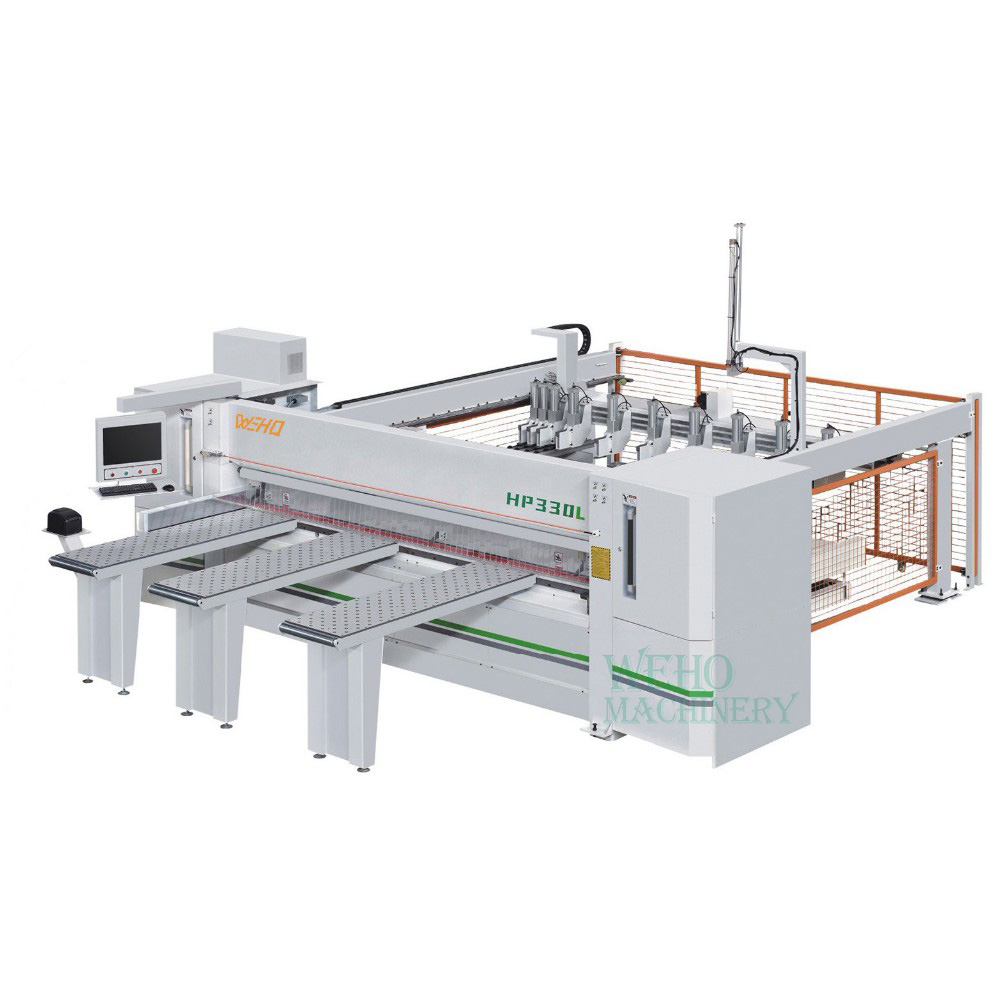

Optimising computer controlled CNC heavy duty wood beam panel saw machine back load feeding

Model:HP300L

Max.Working Width(mm):3280 mm

Workpiece thickness:100 mm

Main saw blade:15kw/20HP

Max cutting length:3300 mm

Main saw power:18kw

Weight (KG):8100 KG

Max.Working Width(mm):3280 mm

Workpiece thickness:100 mm

Main saw blade:15kw/20HP

Max cutting length:3300 mm

Main saw power:18kw

Weight (KG):8100 KG

Details

Spare Parts

Inquiry

Standard Pressure NUMERICAL CONTROL WOOD BEAM SAW, Main motor 18KW, maximum height of saw blae 100mm, clamper speed is 120 meter/min, double sides wheels, with optimized software and printer.

Computer Beam saw cutter is updated products in the panel saw industry, with high cutting accuracy and stable cutting. With furniture development, rapid development of the industry, manufacturers spent huge human and financial resources on cutting plates. Computer Beam saw cutter is updated products in the panel saw industry, with high cutting accuracy and stable cutting. With furniture development, rapid development of the industry, manufacturers spent huge human and financial resources on cutting plates. The disadvantages of using the sliding table panel saw in the cutting of plates becomes more and more obvious: insufficient precision, edge collapse, fault, work injury and other phenomena often occur, which brings obvious constraints to development of enterprises.  1.Environmental protection: dustproof curtain can make the work environment more clean, more accurate sawing. 2.The cutting board workshop dust, reduce the harm to human and environment cleaner production, low noise. 3.Operation is simple, easy to understand: do not need to use skilled workers, a teacher will be, you can save the cost of the material master please. 4. Man-machine integration operation, directly on the touch screen to enter the size of a variety of sizes and then automatically starting.   WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We design and manufacture PRESSURE NUMERICAL CONTROL WOOD BEAM SAW in China,Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

|

HP330L

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Max.cutting length

|

3280mm

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Max.cutting width

|

3280mm

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Max.height of blade

|

100(120)mm Intellingent lifting

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Main saw blade

|

400x4.4x75x72Tx140 Optional 450x4.4x75x72Tx140

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Scoring saw blade

|

160x4.4/5.4x45x24T

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Forward speed of saw carriage

|

5-100m/min

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Backward speed of saw carriage

|

0-100m/min

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Forward speed of PRF program fence

|

0-100m/min

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Backward speed of PRF program fence

|

0-100m/min

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

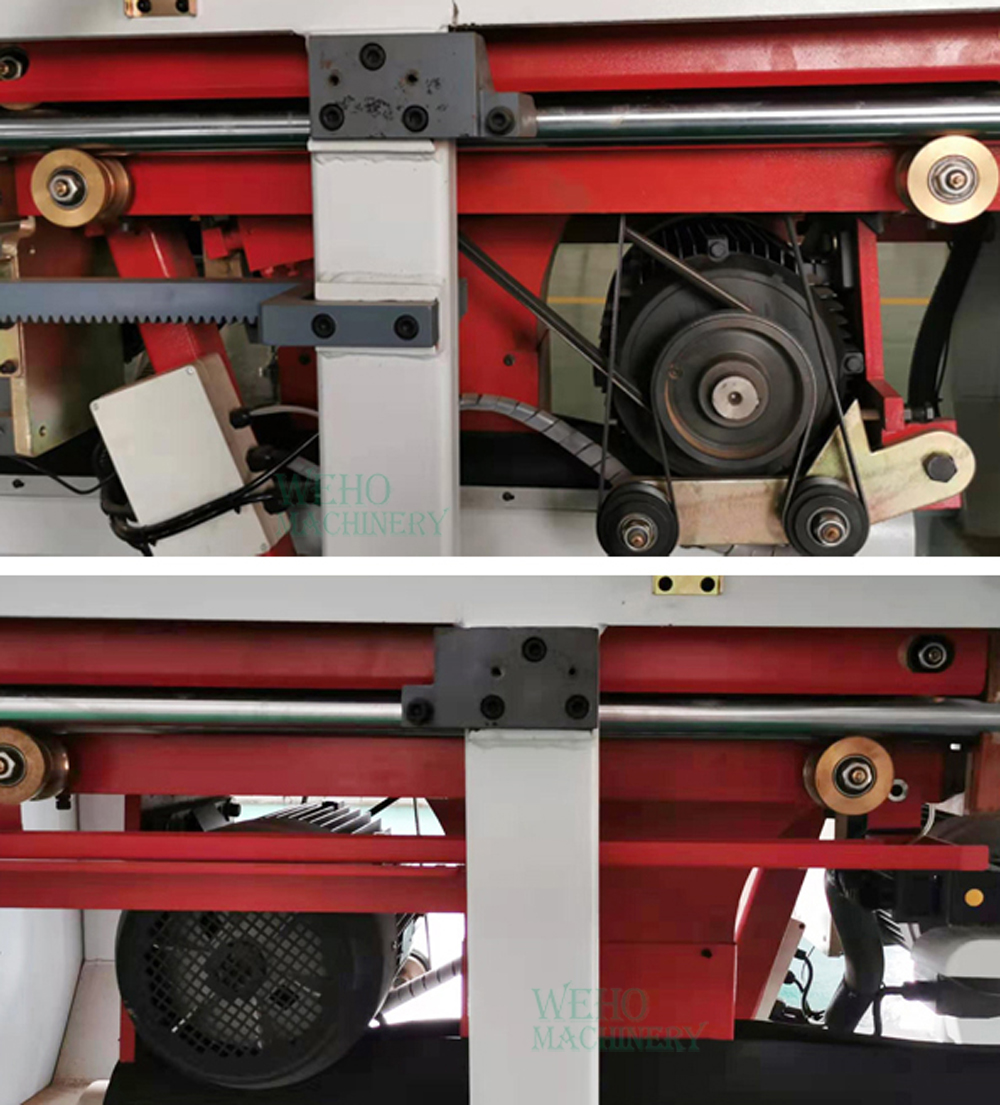

Side pressure device

|

Pnenmatic double side pressing wheels

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Motor power of main saw shaft

|

18.5kw

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Motor power of scoring saw shaft

|

2.2kw

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Working table's height

|

920mm

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Number of PRF program fence

|

10pcs

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

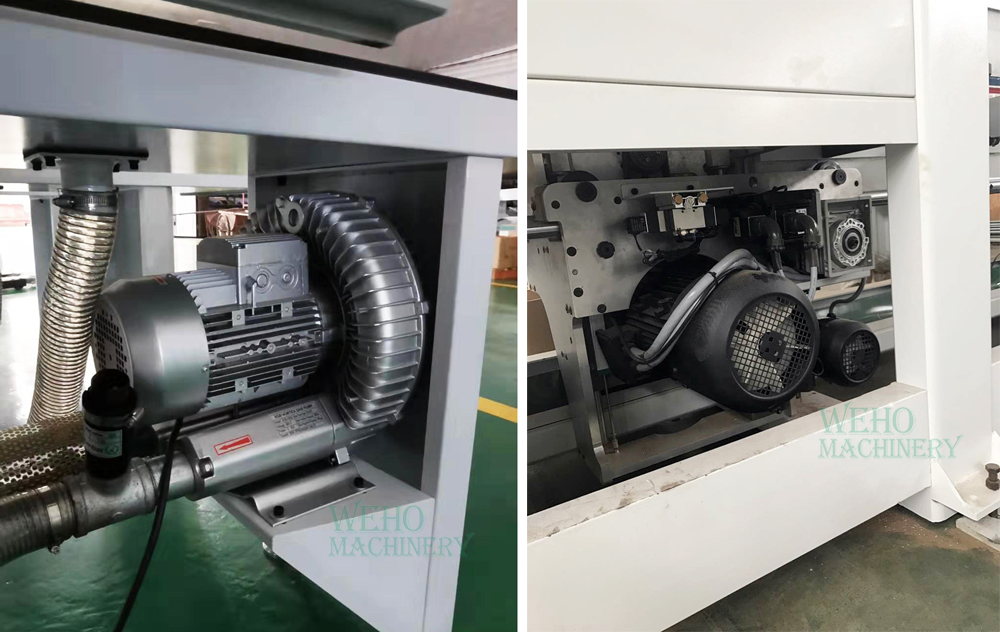

Air floating table

|

3pcs

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High pressure blower of air floating table

|

2.2kw

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Air compression

|

6bar

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Air capacity

|

150L/min

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Min.speed of dust collection

|

26m/sec

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Negative pressure(at least)

|

1200pa

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Input air capacity for dust collection

|

4400m3/h

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Diameter of dust collecting holes

|

200 x 2pcs/ 100 x 2pcs

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

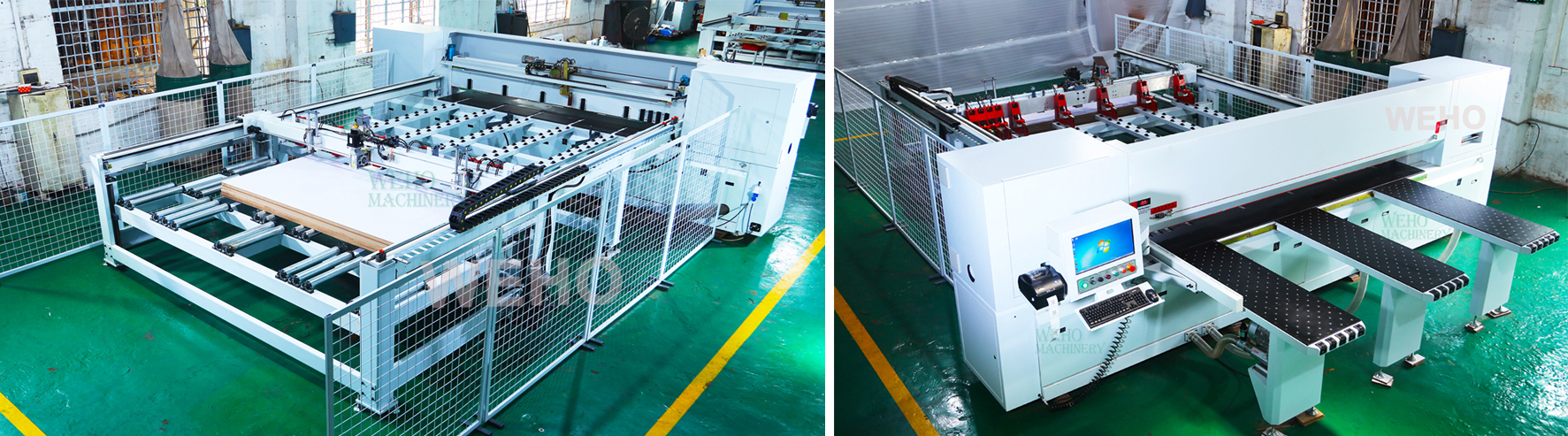

Dimension of rear feeding platform

|

2500x1300x600mm

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Packing size

|

5400x1420x2200mm/4600x920x1000mm//2600x1350x800mm

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Floor area

|

7100x5400x1890mm

|

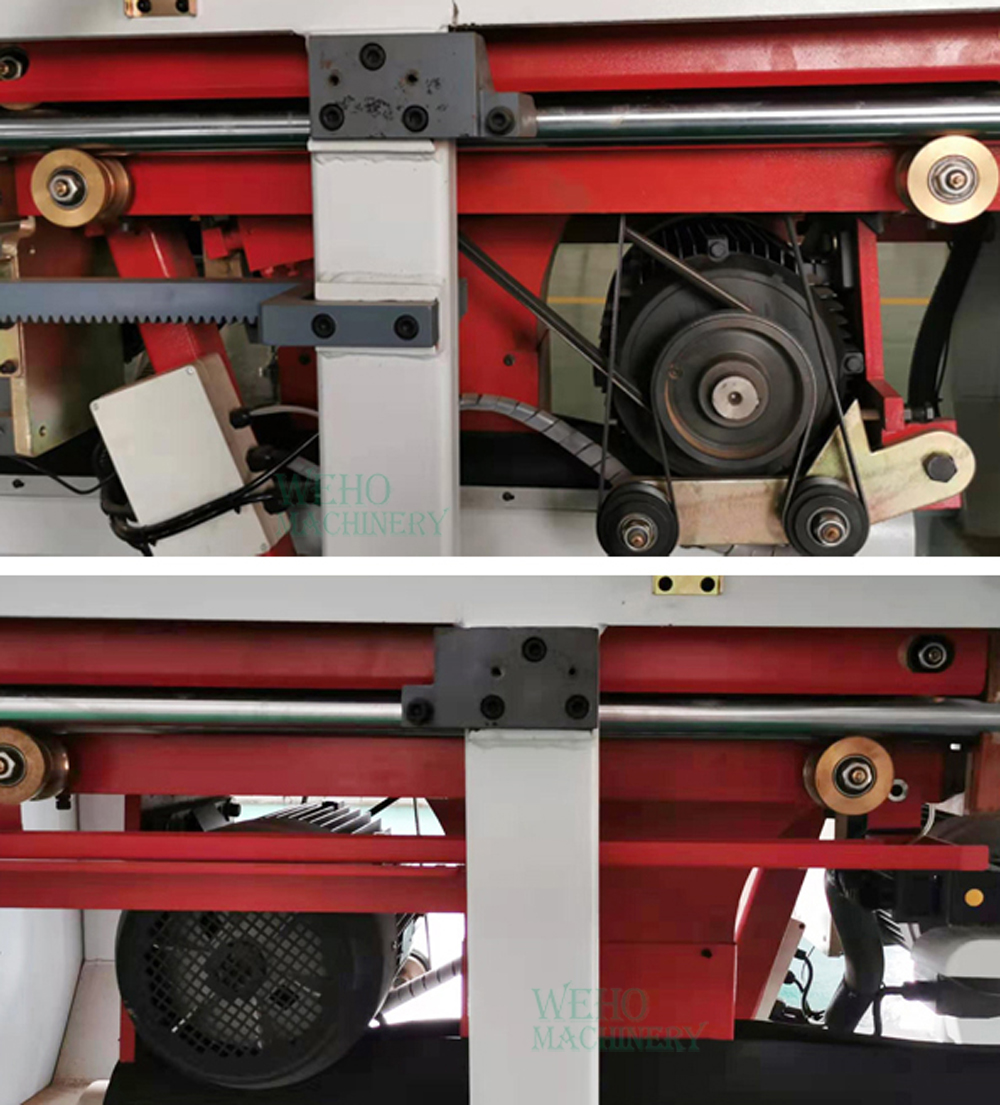

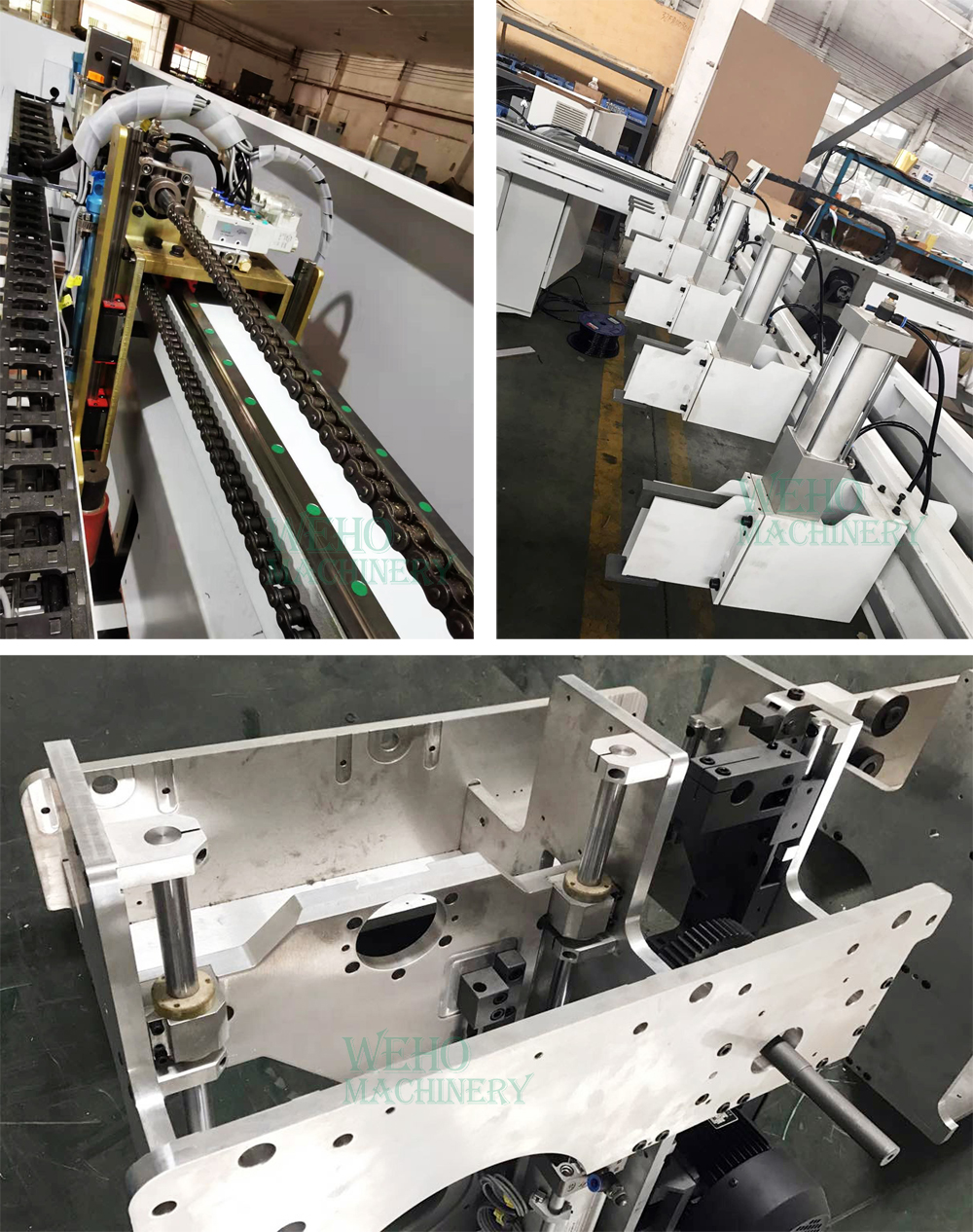

Name: pneumatic feeding clamp

High-performance pneumatic feeding clamp

Name: Aluminum alloy heavy sawing carrage

Aluminum alloy heavy sawing carrage,saw car High-performance pneumatic feeding clamp intelligent lifting,stroke stability

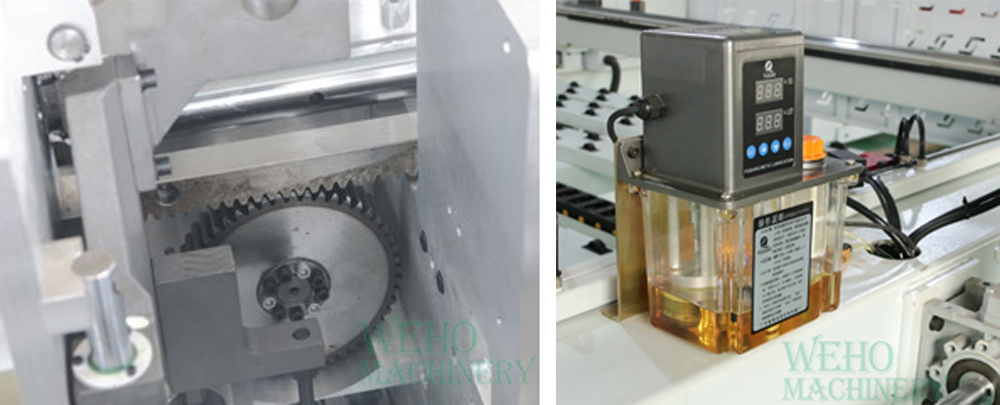

Name: Main saw blade changing device

Pneumatic rapidly changing of main saw blade

Optimising beam saw machine.Precision rack feed drive.

Optimising beam saw machine.Precision rack feed drive. Computer Controlled Optimising beam saw machine.Rear loading platform.

Computer Controlled Optimising beam saw machine.Rear loading platform.

Name: Main saw blade changing device

Pneumatic rapidly changing of main saw blade

Main Features

1) Super Heavy Backload Electronic Saw

2)Maximum sawing thickness up to 120mm

3)Heavy Duty Backload beam Saw

4)Hydraulic lift table

5)Maximum sawing thickness to 120mm

6)Pneumatic Quickly install Main saw blade device

7)Intelligent control lift height of saw blade according to cutting thickness.

8)Intelligent control lift height of pressing beam according to cutting thickness.

9)Control of lifting height according to the thickness of saw cutting board

10)Imported high strength aluminum saw carriage.

11)Saw carriage drive by servo moto.

Name: Aluminum alloy heavy sawing carrage

Aluminum alloy heavy sawing carrage,saw car High-performance pneumatic feeding clamp intelligent lifting,stroke stability.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.