- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

Hydraulic plywood laminating hot press machine for wood veneer bending skateboard mold

Dimension(L*W*H):800 x 3800 x 1800mm

Max.Pressure(T):135T

Working Table Size(mm):1300×2500

Weight (KG):2000 KG

Power (kW):5.5

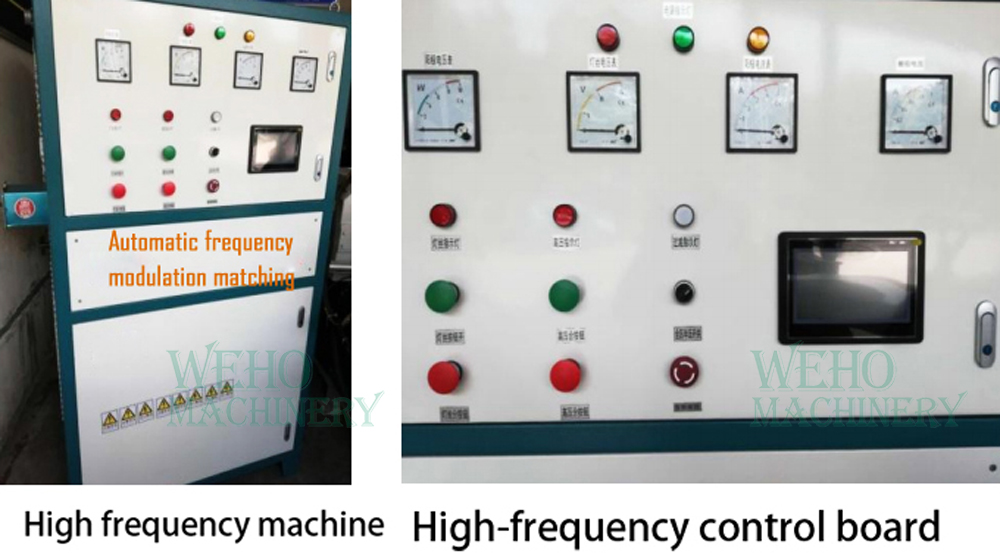

| Model | HFB200 |

| Working methods | High Frequency edge gluing press |

| Vertical pressure | 75T according to different wood |

| side spressure | according to different wood |

| Table Size | 1250*2500 or different customize size |

| Oil cylinder | 6pcs or more |

| Color or logo | Customized available |

| Product aim | quickly and fast auto wood board joining |

Equipment features:

1. High frequency medium heating, even heating, rapid glue curing (2-3 minutes)

2. The wood mould has the advantages of low cost, small heat loss, simple operation and convenient replacement

3. High setting, not easy to deform

4. The best combination of one belt and two, one working, one preparing, two working alternately, shorten working time and improve working efficiency

5. Environmental protection and no pollution

6. 25 years of manufacturing experience, multiple protection of equipment, safe and assured.

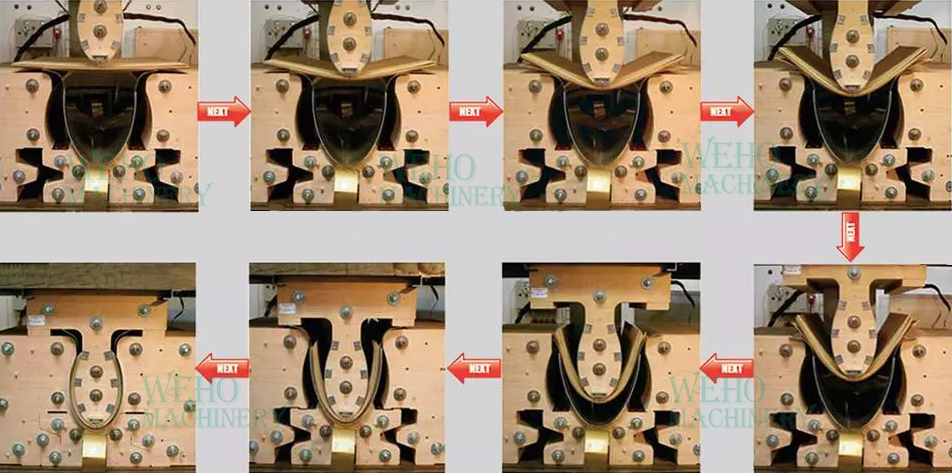

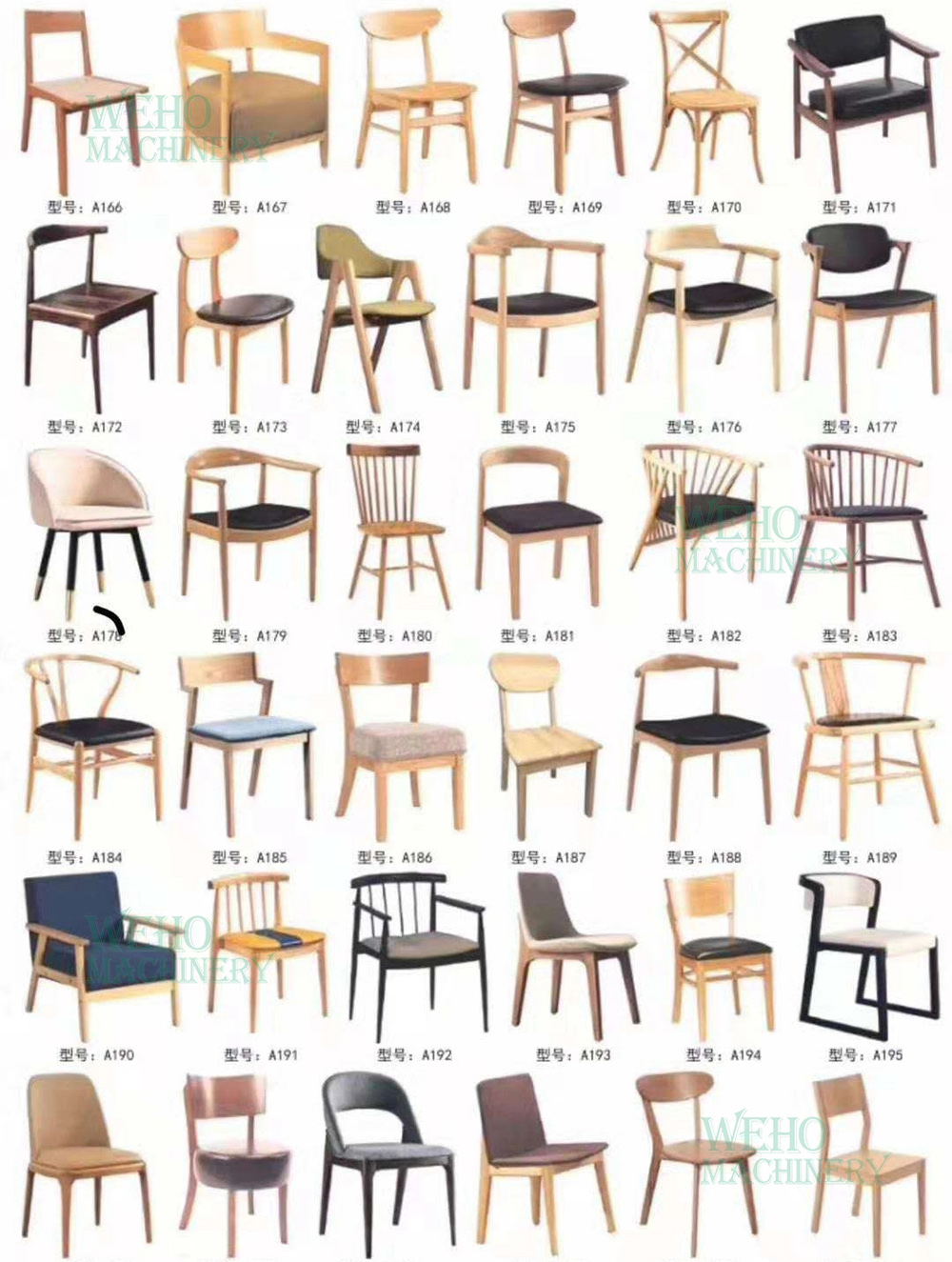

Production of curved wood sofa, table and chair, curved wood furniture, musical instrument curved surface, wooden shoe bottom, etc.

High frequency heating can be used to complete the pressing and shaping of products at one time. One set is: one belt one, one drag two, one drag three, one drag four.

HF plywood press use, put glued wood veneer or solid wood veneer, composite paperboard and other composite plates into the prefabricated mold, apply appropriate pressure, apply high-frequency voltage, the glue in the workpiece is rapidly heated and solidified under the action of high-frequency electromagnetic field, and the mold can be opened, finished product can be taken out after proper cooling.

HF woodworking press Advantages:

1. Through heating, uniform heating, rapid qualitative, only tens of seconds to a few minutes.

2. Adopt wood mold, low replacement cost. One way, three-way and multi-way hydraulic presses can be flexibly combined.

3. It has good stability and does not deform for a long time after forming.

4. Environmental protection, no pollution, no dust.

Simple operation, uniform heating, rapid setting, only a few minutes to more than ten minutes.Adopt wood mold, low cost, simple replacement, easy variety innovation.

One way, three-way and multi-way hydraulic presses can be flexibly combined to meet different needs.

Single high-frequency machine can be equipped with multiple presses, with small working area and low labor intensity.Environmental protection, no boiler, no dust, no smoke.

HF plywood press produce many kinds of bending wood products, such as sofa, desk and chair, panel furniture, bed side cabinet and so on, which can be finished by high-frequency heating.

Due to the use of high-frequency heating technology, the variety of products changes a lot, mold replacement is easy, and the production efficiency is several times or even dozens of times of the traditional heating or cold pressing. High frequency curved wood press to become a special product of furniture industry.

The equipment can be used for gluing, shaping and bending of multi-layer boards and density boards. It can be used in the processing and production of office tables and chairs, sofa armrest, bed keel, panel furniture bedside, cabinets, musical instruments and other curved wood pieces.

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines. Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

Hot Press Machine For Wood

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.