- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

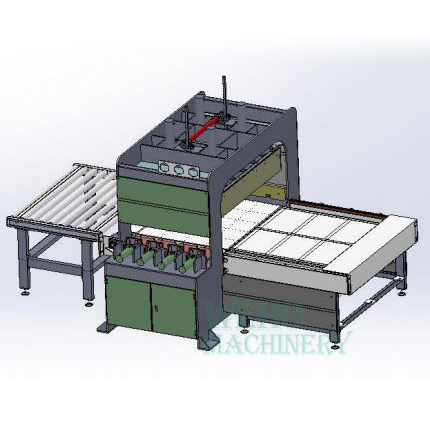

High frequency wood side edge gluing press wood board joining machine

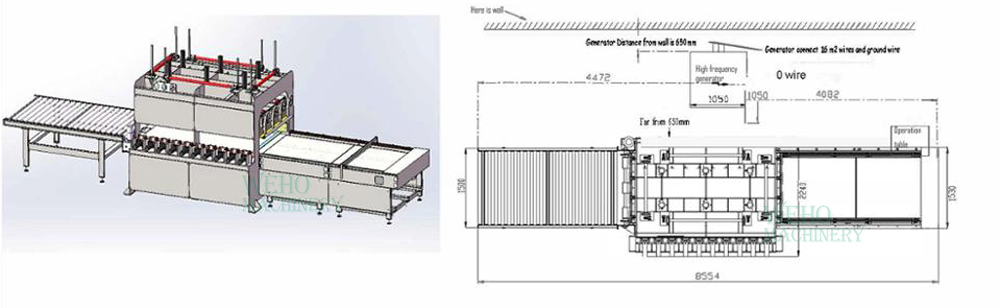

Working Table Size(mm):1300×2500

Dimension(L*W*H):800 x 3800 x 1800mm

Max.Pressure(T):135 T

Weight (KG):2000 KG

Power (kW):5.5

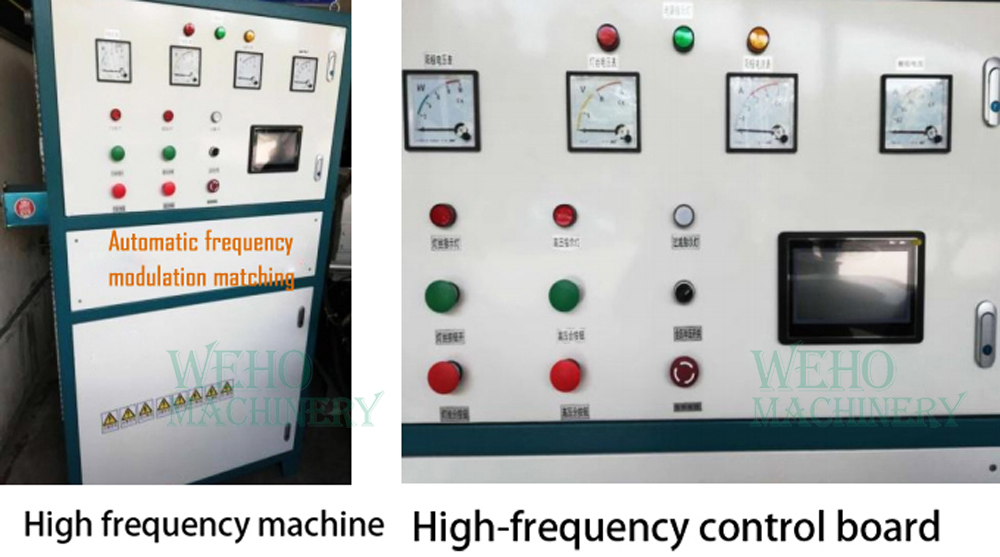

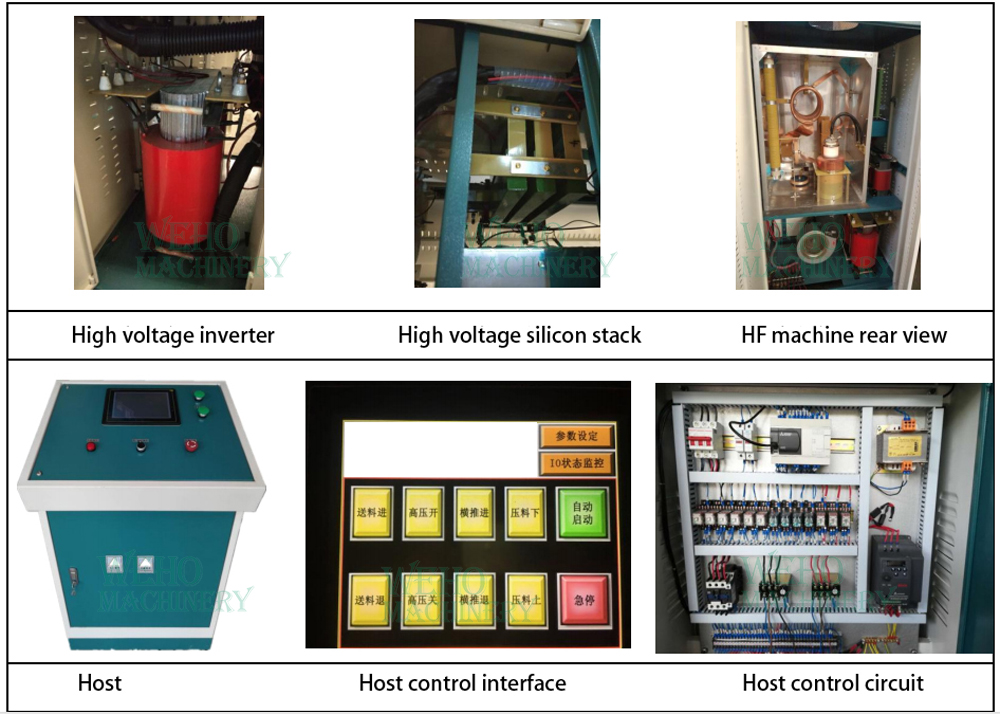

Electric heating Join wood press Glue laminated plant RF HF press solid panel edge wood strips joining machineThe wood strips joining machine consists of the main body, high-frequency generator, hydraulic station, feeder, discharge table and control system. The machine is controlled by Delixi Electric circuit.

| Model | HF1325Z |

| Joining boad length | 2500mm |

| Joining panel width | 1300mm |

| Joining board Thickness | 5-130mm |

| Vertical cylinder pressure | 60T |

| Vetcial cylinder qty | 6pcs |

| Side cylinder pressure | 75T |

| Side Cylinder Qty | 10pcs |

| Motor power | 5.5KW |

| High Frequency Rated out put | 30KW |

| Dimenstions | 1500*3800*1800mm |

It has high automation, simple and convenient operation, low labor intensity, short joining cycle and labor saving.

It is an ideal equipment for splicing of integrated materials and plates, and bonding of composite solid wood. The splicing size are customized, 5mm to 130mm thickness can be spliced by different models.

We customize glue laminated machine with different sizes and configurations according to requirements.We provide optional automatic chain wheel feeding / automatic push feeding, and the rear worktable has no power roller for discharging.

It adopts high-frequency heating and two-dimensional pressure, and is used for panel splicing, wood strip edge banding, integrated wood splicing, door edge banding, door edge banding, L-shaped door frame line combination, door core plate splicing, especially suitable for panel splicing, with the thinnest up to 3-5mm.widely used in furniture, wooden doors, integrated wood and other industries.

The equipment adopts high frequency heating, which can make the adhesive solidify quickly in a short time. The whole working process is about 3-5 minutes.When users have special requirements, we can carry out customized configuration design accordingly.

Wood strips joining machine is applied to:

1. Chair panel / integrated material panel / joinery panel core panel splicing;

2. Splicing of solid wood doors and windows, splicing of door panel core and edge banding of solid wood strip;

3. Laminated, parquet floor gluing;

4. Splicing of dining table and conference table;

5. Glulam lamination, batten edge sealing and frame combination;

6. Splicing of cabinet door and electric guitar

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines. Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.