- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

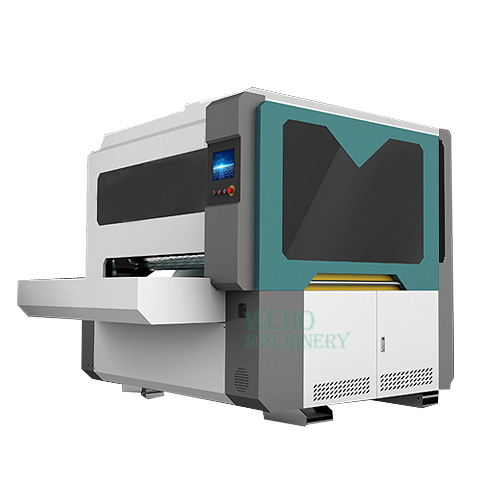

Heavy high speed power wood sander transverse and longitudinal polishing for Embryo Primer sanding

Model:MF1300-C3

Sanding width:100-1300mm

Sanding thickness:5-100mm

Minimum length:400mm

Power:6.75kw

Weight:1800kg

Sanding width:100-1300mm

Sanding thickness:5-100mm

Minimum length:400mm

Power:6.75kw

Weight:1800kg

Details

Spare Parts

Inquiry

Wide range of processing, such as solid wood furniture, solid wood doors and windows, cabinets, wardrobes, desk tops, tea tables, TV cabinets and other industries of white and primer sanding, and will not sand through the corner.

| Model | MF1300-C3 |

| Sanding width | 100-1300mm |

| Sanding thickness | 5-100mm |

| Minimum length | 400mm |

| Feeding speed |

0-10m/min |

| plank embryo | 0-6m/min |

| Primer | 0-5m/min |

| Longitudinal sand speed (c)of sand roller | 0-220r/min |

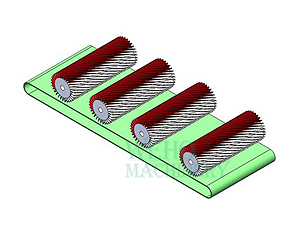

| Sanding Roller longitudinal sand (c) | 3 groups |

| motor power | 3 x 1.5kw (frequency control) |

| Diameter of sand roller | φ300mm x3pcs |

| Conveyor belt motor power | 1.5kw(frequency control) |

| lifting motor, components and pressure roller power | 3 x 0.25kw |

| Dust collector | φ150 x 4pcs |

| Total power | 6.75kw |

| Overall size | 2600*2300*1950mm |

| Total Weight | 1800kg |

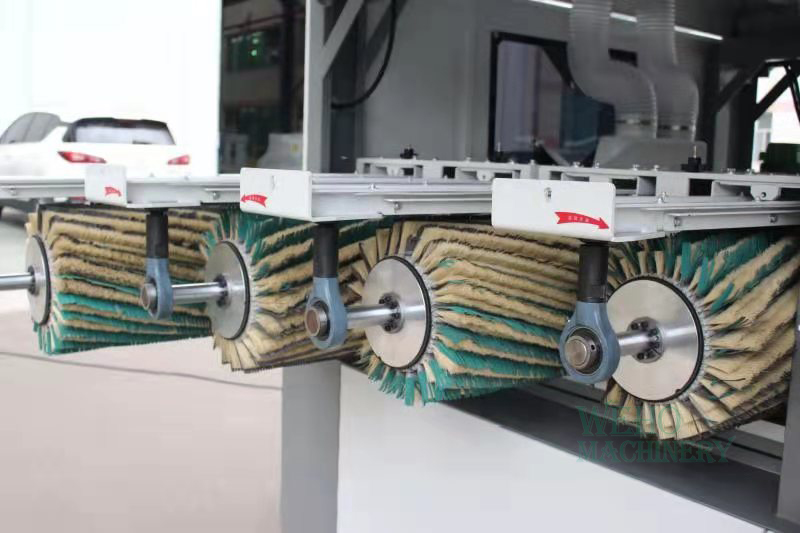

The sand roller is composed of several brushes and sand cloth strips,

The brush forms an angle with the axis,

Rotating speed control by frequency conversion,

Independent lifting control, convenient abrasive replacement.

Features: from top to bottom angle, rolling all-position polishing, flexibility in traditional grinding , the concave of the plate Grinding and sanding of irregular surface and corner.

Name of wearing parts: brush abrasive strips (customized according to different grinding products) are imported and domestic abrasive strips respectively; The number of commonly used sand cloth strips is 180 #, 240 #, 320 #, 400 #, 600 #.

Name of Wearing parts: sisal brown brush, with sanding cloth strip; The minimum service life is 1 year and the maximum is 2 years.

The specific service life depends on the use and maintenance.

Surface sanding machine, with different sanding roller and different sanding material combined to sanding Embryo or Primer.

Adopts heavy structure and integral frame,ensure the stable operation and sanding accuracy of the equipment.

Large imported processing equipment workshop to ensure the processing accuracy and quality of product parts.

Machine base, beam, worktable, stress relief annealing treatment;CNC gantry machine one-time forming processing;Stable structure, high precision and small deformation;Machining parts are the basis of machine quality

Embryo Primer sanding

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.