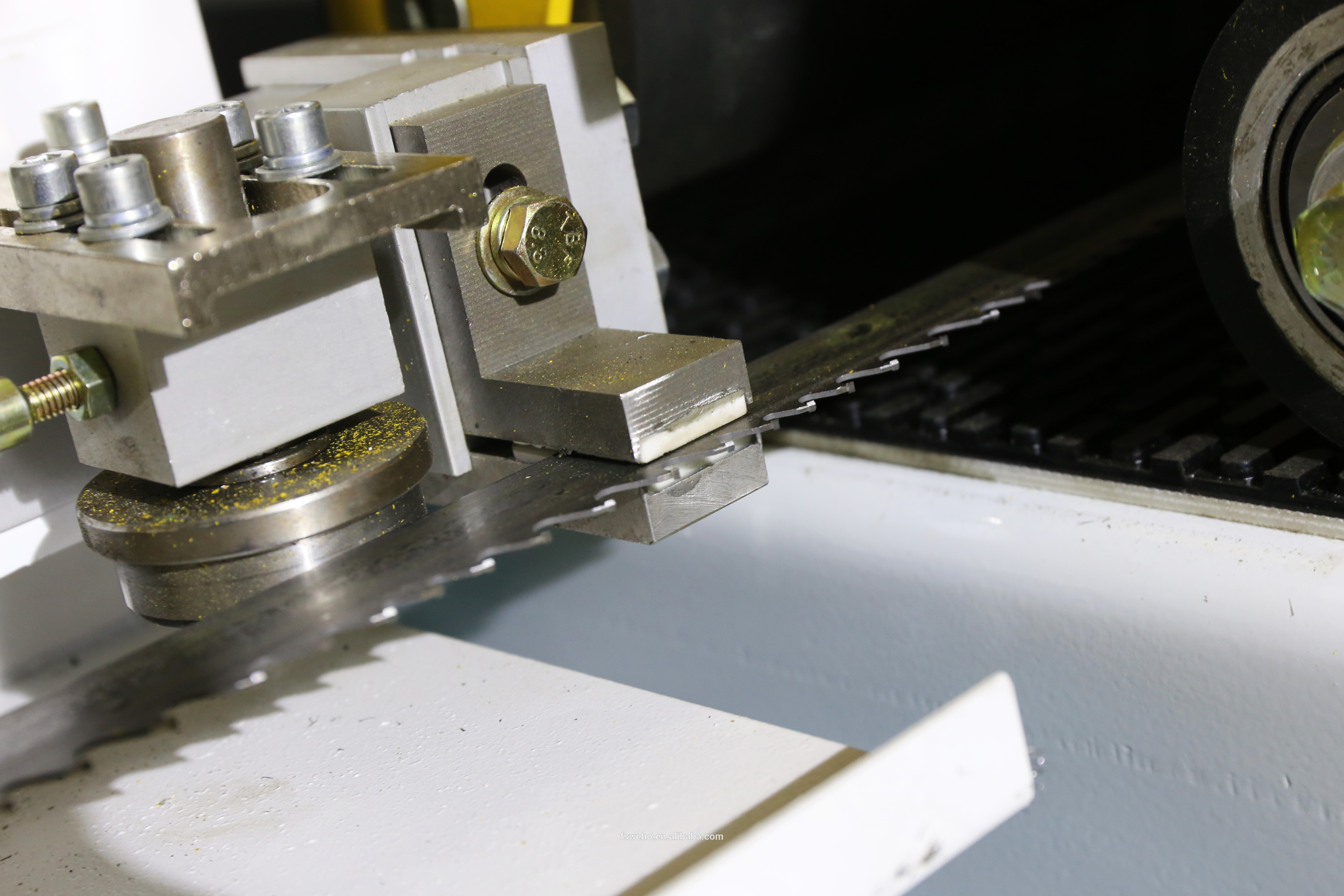

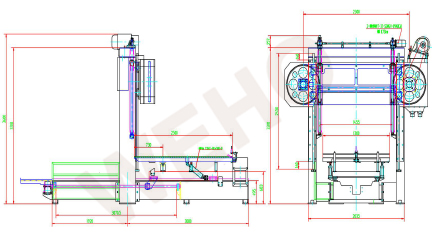

| Parts: Ceramic saw clamp | Parts: Tensioning system |

| Wear-resistant ceramic saw clamp to protect the saw blade for efficient heat dissipation and better sawing surface quality. | Automatic tensioning: The Rexroh rails are fitted with a tensioning system to make the saw blade more durable. |