- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

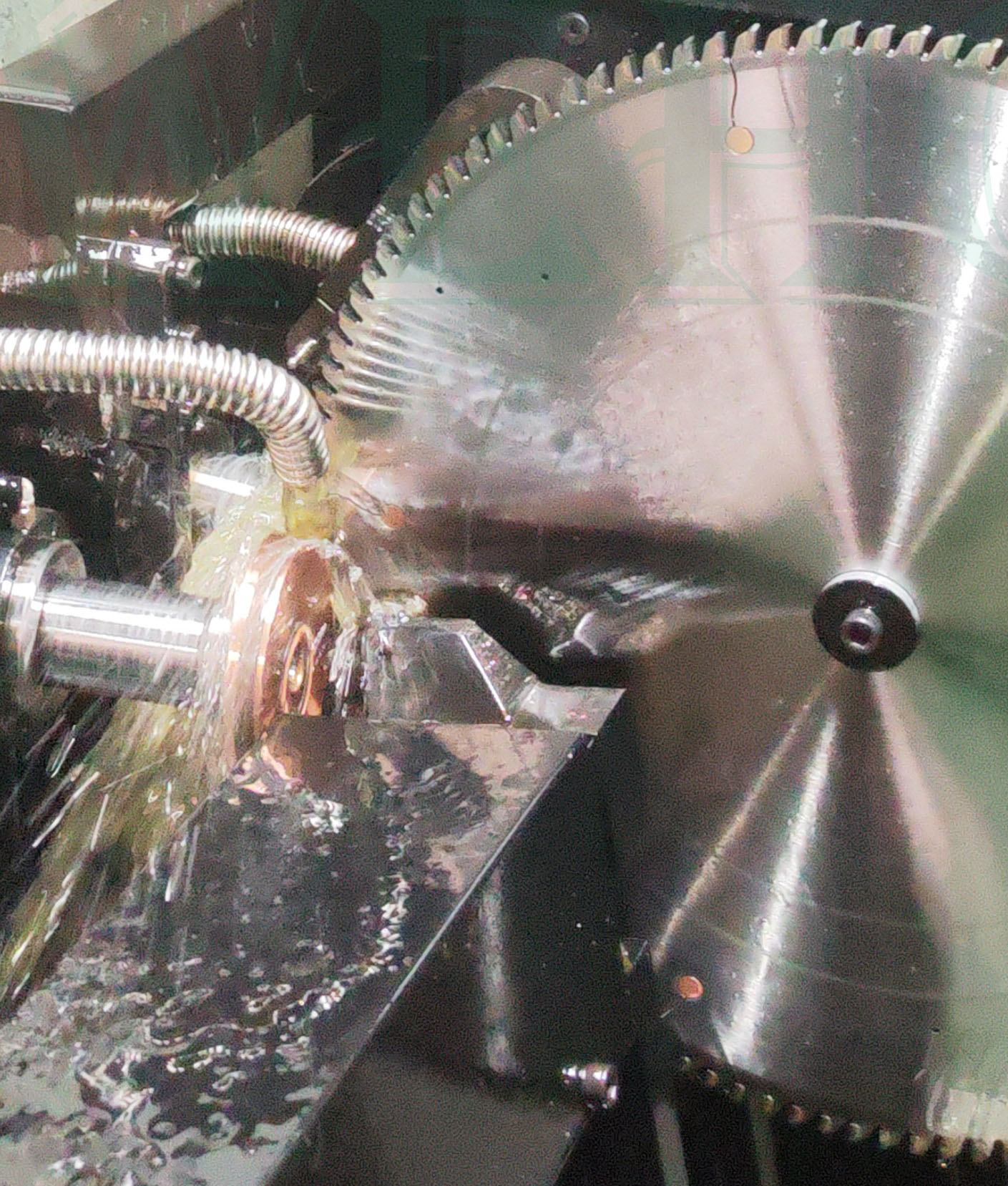

EDM Top Grinding Machine realize discharge machining of various tooth shapes PCD circular saw blades

Model: MFD800D

Machine Bed Dimensions(longxwidexhigh): 1900x1890x1920mm

M achine tool Weight: about 2200Kg

X-axis travel: 45mm

V1,V2 Axis travel: 50x50mm

U-axisSliding table stroke: 400mm

E axis to axis rotation: -5°~20°

X\V1\V2\Uaxis resolutionum: 1um

| Model | MFD800D |

| Machine Bed Dimensions(longxwidexhigh) | 1900x1890x1920mm |

| Machine tool Weight | about 2200Kg |

| X-axis travel | 45mm |

| V1,V2 Axis travel | 50 x 50mm |

| U-axisSliding table stroke | 400mm |

| E axis to axis rotation | -5°~20° |

| X\V1\V2\Uaxis resolutionum | 1um |

| E-axis resolution | 0.1 |

| Saw blade machining accuracy(Turntable Inspection)mm | ≤board jump 0.02mm |

| Grinding efficiency(Z120D5000 saw blade, bladed on both sides, ground 0.2mm) | 520M/min (E6 or Sifangda PCD,teethlong6.8mm) |

| Edge finish | ≤ Ra0.4 μm |

| Machine tool noise | <78db |

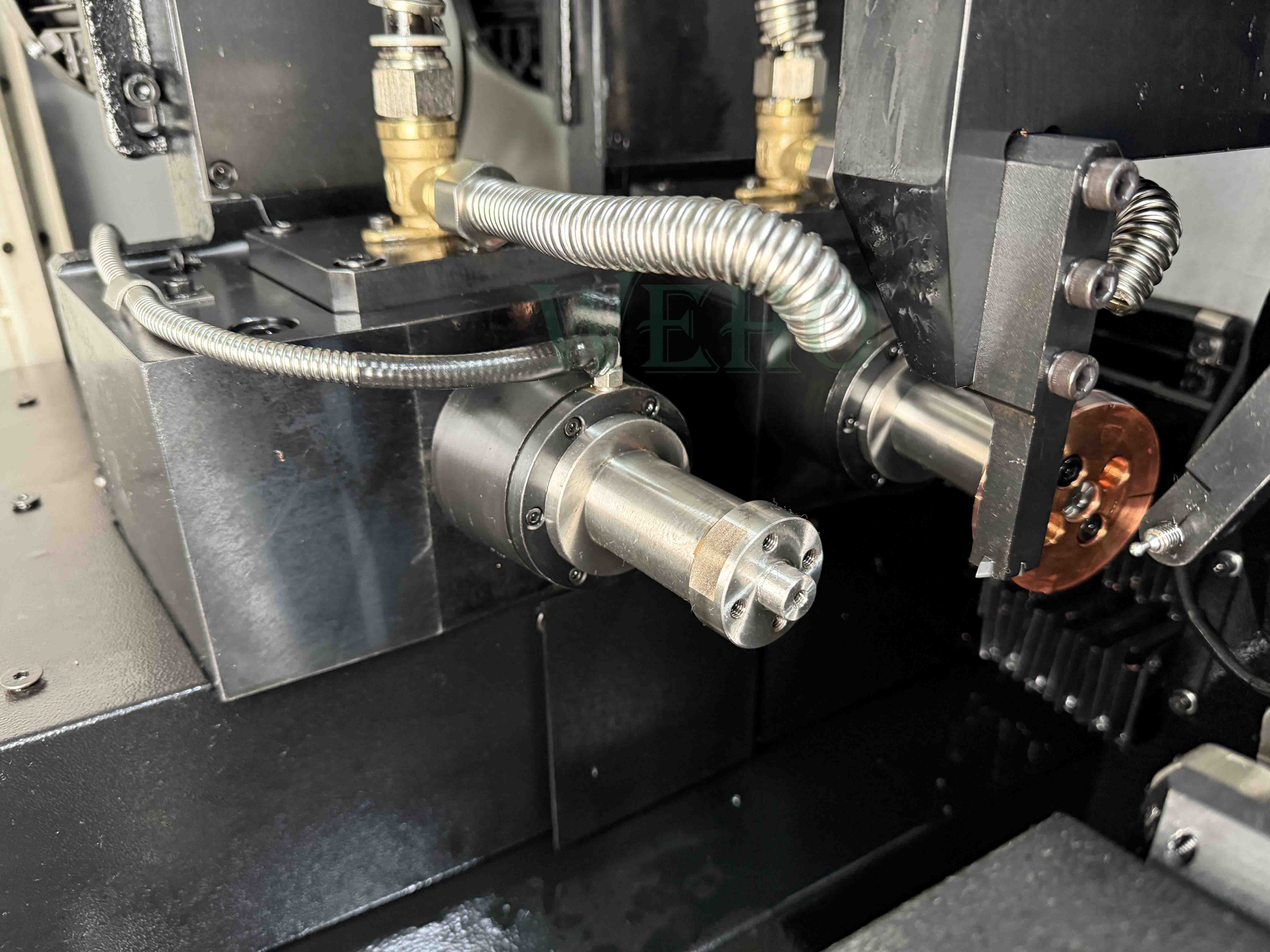

MFD800D saw blade processing special machine is two PCD saw blade sharpening and grinding equipment with unique design concept. The machine adopts multi-axis numerical control, stepless speed regulation grinding head and original concentric circular tooth mechanism, which can realize discharge machining of various tooth shapes PCD circular saw blades.

● Elf-developed control system

1. using advanced industrial level computer, LCD touch screen, genuineWindows embedded standardoperating system, combined with self-developed fill-in-the-blank humanized design of EDM grinding CNC software, to control the machine tool.

● Automatic turning compensation

1. In the process of machining, the electrode wheel loss can be set in advance, and the turning compensation can be made again during the machining process, so as to avoid the inaccurate machining accuracy caused by the electrode loss during the machining process. all the operation process is not only convenient and fast, but also effectively improve the accuracy of the saw blade production, multi-tooth tool processing process can be completed automatically without human intervention.

● CNC gear

1. CNC tooth dial concentric circle tooth dial tooth technology, greatly reducing the non-processing time, improve the indexing accuracy, expand the saw blade can be processed range, in line with the same grinding with the processing principle, so that the saw blade practical effect is better.

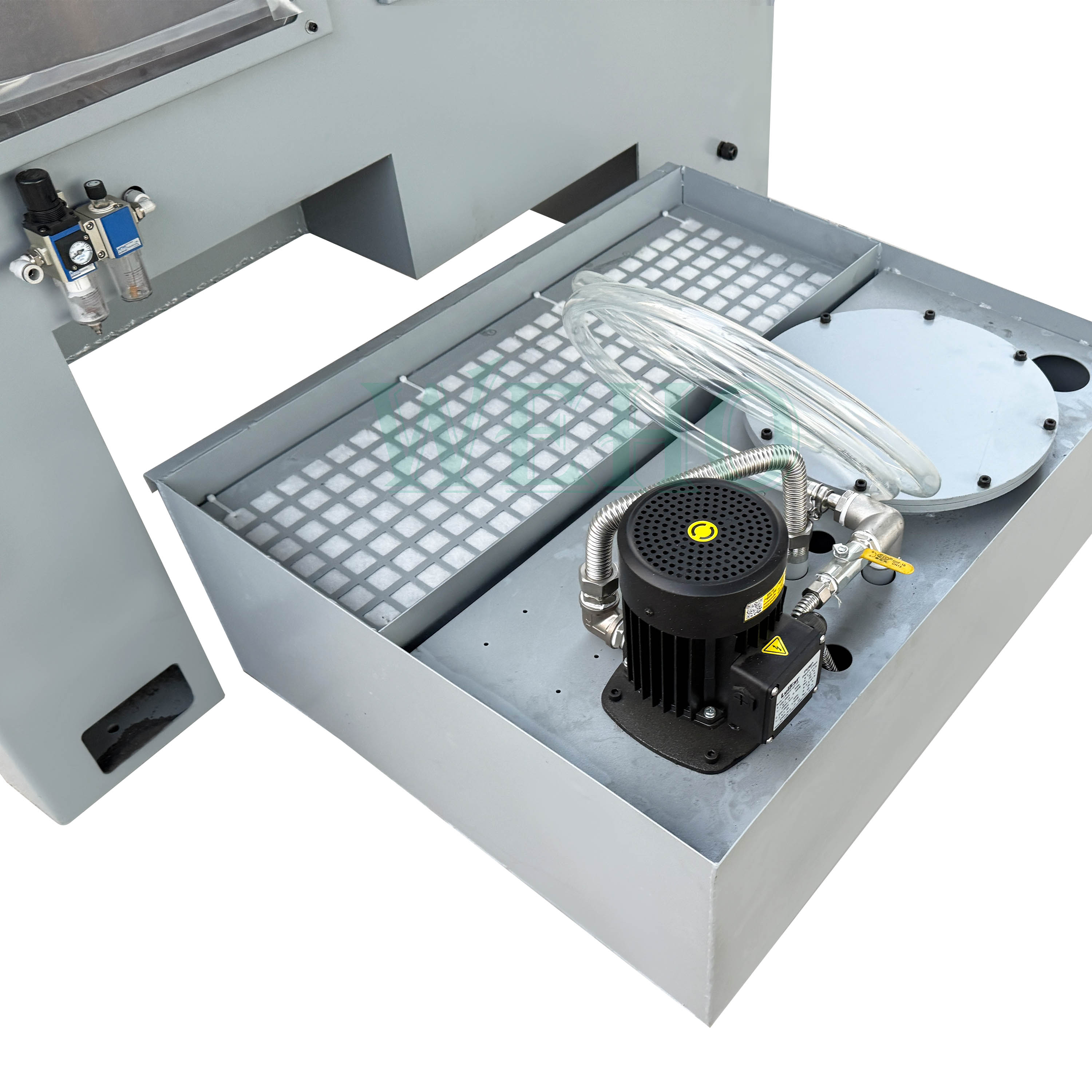

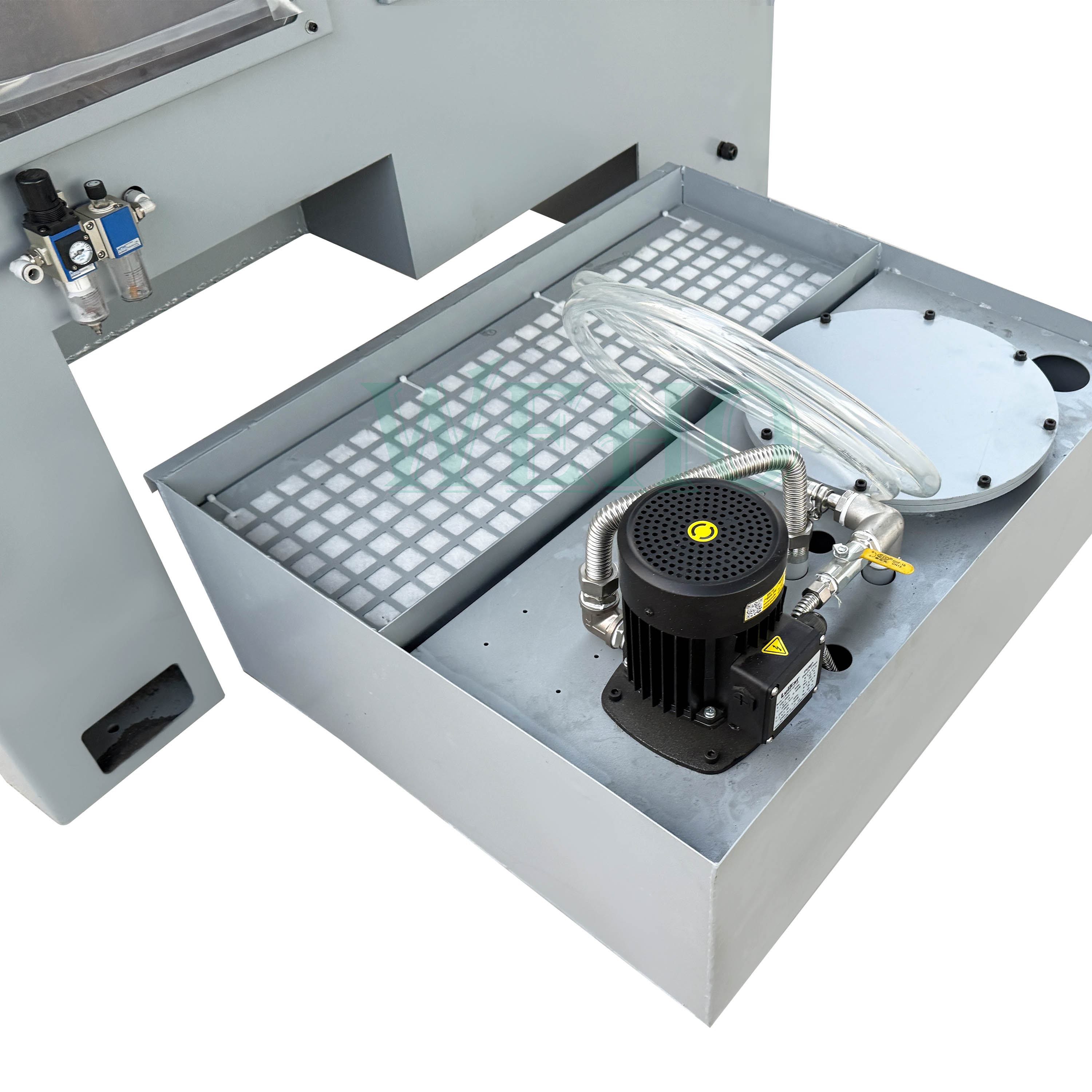

● Powerful standard configuration and control system

1. high power rigid precision grinding head

2. Pneumatic presser foot, to achieve stable processing of saw blade saw blade card using variable diameter sleeve, simple and economical

3. Manual/automatic sliding table expands the application space of the machine tool, which can not only process small saw blades, but also process large saw blades, realize the function of cutting in the turning process, and avoid short circuit of copper cutting.

4. air pressure system ensures the stability of the machining process, and the transmission system is controlled by Panasonic AC servo motor.

5. PMIprecision ball screw and precision linear guide to ensure accurate positioning.

6. automatic lubrication system.

7. use low cost copper electrode wheels.

8. empty walking speed, processing speed adaptive adjustment fast forward and backward, accurate and reliable motion positioning

9. can interrupt the processing of teeth in one cycle, one clamping and one forming.

● Quick and convenient operation

1. tooth type library is rich and has extended functions, which is simple to sharpen and minimize the difficulty of operation. There is no need to adjust the tooth spacing and basic thickness, and it has the function of jumping teeth.

2. power supply and intelligent discharge gap control system

the adoption of innovative ideasPCDspecial energy pulse generator, strictly control the actual discharge pulse width and pulse gap, reduce electrode loss,make the processing surface uniform, combined with the intelligent discharge gap control system can improve the pulse utilization rate to the best state to further improve the processing efficiency, accuracy and smoothness. In the process of processing the user according to the actual needs of numerical control programming, automatic processing machine can start according to the operator set the parameters and depth of rough, medium and finishing automatic processing.

How to buy

1. Contact WEHO sales and provide your requirents to get best solutions

2. Order confirmed, get invoice, contract from WEHO.

3. Normally, producton started against TT by 30% deposit.

4. After one week, WEHO sales inform you production state and delivery date.

5. Order finished, WEHO sales send you photos, videos and spare parts for confirmation.

6. Book shipping order, delivery the machine to your port.

How to do if I can not operate

When you get the machine, if you have operation problem, we will make video meeting to teach you. If video teaching can not solve, our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for weho machines, including find problems, send spart parts, and teach you to replace the parts.

Service contacting

Before buying, choose suitable model contact Whatsapp 008613378477841. After buying, technical supporting contact 008613326792205

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.