- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

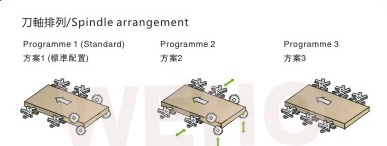

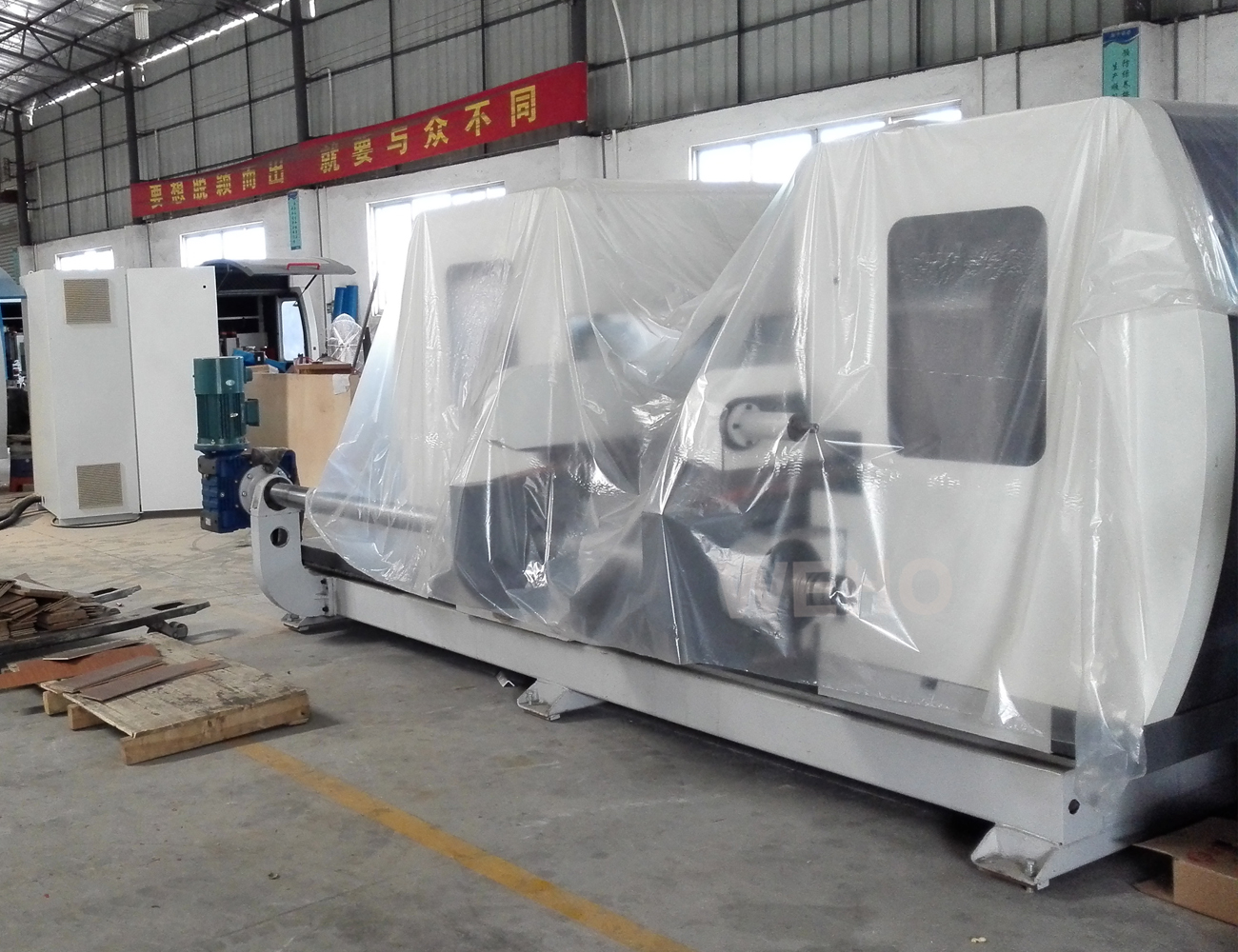

Double head miter saw for wood cutting machine pallet wood double end decorative saw

Model:MB283A

Working width:300-2400mm

Working thickness:10-25mm

Maximum cutter diameter:200mm

Extraction outlet size sion:120mm

Working width:300-2400mm

Working thickness:10-25mm

Maximum cutter diameter:200mm

Extraction outlet size sion:120mm

Details

Spare Parts

Inquiry

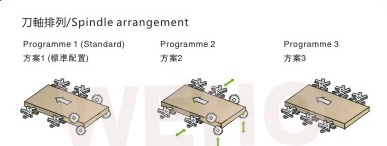

Applicable to real wood floor, multi layer floor, etc.-Frequency control of motor speed, high precision conveyor chain rolling guide feed system; -Passive pressure on the strip; -Double linear guide.

| Double head miter saw for wood cutting machine pallet wood double end decorative saw | |||

| Feeding speed | 6-30m/min | Sawing shaft diameter | φ25.4mm |

| Min. working width | 300mm | Width adjusting motor power | 0.75kw |

| Max. working width | 2400mm | Total power | 32.65kw |

| Min. working thickness | 10mm | Spindle speed | 6000r/min |

| Max. working thickness | 25mm | Power take-off and landing | 0.25kw |

| Feed motor power | 3kw | Air pressure | 0.6mpa |

| Scoring saw motor power | 3kw*2 | The length from feeding end of top pressing beam to dog | 400mm |

| Main saw motor power | 3kw*2 | Sawing shaft rotation | 2800 |

| Vertical spindle motor power | 3kw*4 | Max. mini saw blade diameter | φ230mm |

| Card buckle spindle motor power | 2.2kw*2 | Max. scoring saw blade diameter | φ230mm |

| Maximum cutter diameter | φ200mm | Main spindle dimension | φ230mm |

| Extraction outlet size | φ120mm | Overall size | 3500*4600*1780mm |

| Vertical spindle rotation | 9000 | Weight | 5000kg |

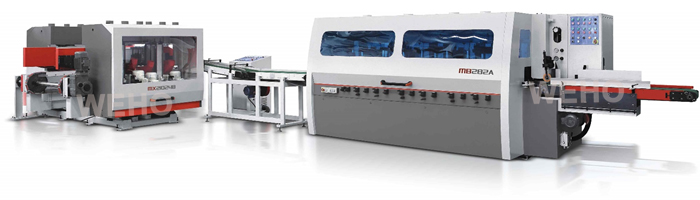

The floor plates are sent into the running bearings of the machining track with the material feeder and delivery rubber rollers, and the guide rails are made with extra hard materials, ensuring the machining precision.

With the imported PLC and the frequency conversion device, the double-end miller works very smooth.Forcefully feeding decelerator features speed regulation by frequency inverter.With the built-in cleaning brush wheel, the dust inside the track guide rail can be cleaned automatically.

With the compact sawing shaft mechanism, the cutters are closed to the pressing belt, ensuring the machining stability.Structure acting as ball-screw makes machine have more accurate adjustment.

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines.Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

Wood Cutting Machine

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.