- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

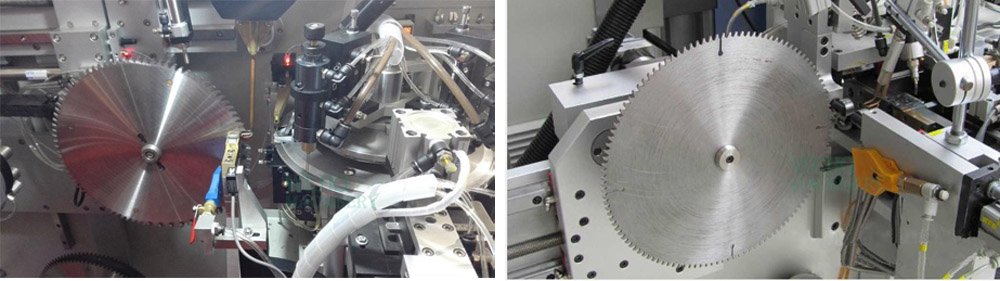

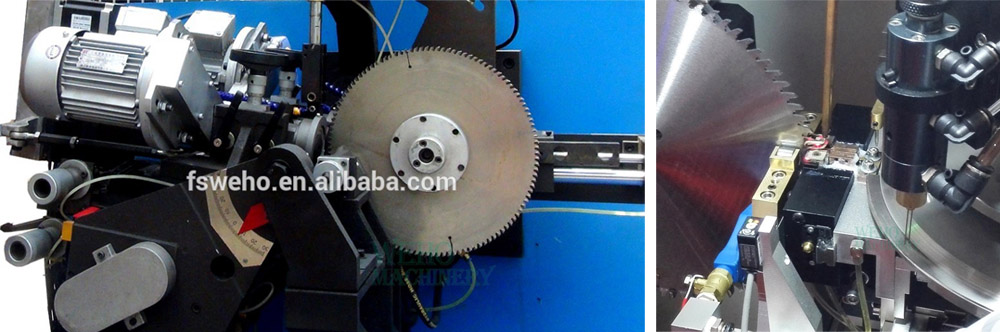

Circular saw blade welding and tip teeth brazing machine | Carbide Tip Brazing Machine

Saw blade Dia:120mm-790mm

Saw tips width:1.5mm-6.5mm

Saw tips thickness:1.5mm-3mm

Power:6kw

Overall size:1570*1100*1600mm

Automatic saw tipping Machines offer tremendous flexibility and cost-savings to your company. A single automated machine is capable of precise, exact brazing of over 3500 tips per day without fail.

1.Automatic choose tooth, feeding, soldering lug fold to mould, centering and welding.

2. Accurate and durable welding quality.

3.Advanced heated controller, control temperature automatically in welding work, micro adjustment temperature of automatic tempering.

4.Centering precise, welding secure.

5.Latest system for teeth type choose.

6.CNC control, safety performance, has memory and search function.

7.Small size of whole machine, low power consumption, high working efficiency.

8.Easy to operation, clear graph indexing.

| Product name | CNC Circular saw blade welding machine |

| Saw blade Dia | 120mm-790mm |

| Hook angle | -10 to +25 degree |

| Saw tips length | 3.5-13mm |

| Saw tips width | 1.5mm-6.5mm |

| Saw tips thickness | 1.5mm-3mm |

| High frequency power | 6kw |

| Air pressure | 6KG/cm2 |

| Total power | 6.5kw |

| Ventilate capacity | >5meter/min |

| Cooling power | 1.5kw |

| Cooling water flow | 22L/min |

| Weight: | 430KG |

| Overall size | 1570*1100*1600mm |

Integrated robot system with high storage capacity and very fast movements for loading and unloading the saw blades.

Freely accessible machine protection system with light curtain.

Innovative machine design for fast change over to different saw and strobe sizes.

Most machine settings are programmable,high brazing precision.

Red laser choose corrected side tips to feed in welding device. Remove the incorrect side tips to loading device.

Rotating automatically to make the carbide tips to different side.

Automatic carbide tips choosing.

The wrong direction carbide tips will be return back.

Optical tip sorting for precise results

Quick and exact adjustment to different saw blade sizes

Material cost savings due to exact placement of flux dosing and solder foil placement

Increased efficiency due to reduction in "human error"

Precise, repeatable quality,Reduced labor costs

For visual assistance, our multimedia gallery provides videos of WEHO Automatic tipping Machines in action

TRUSTAR MACHINERY Provide Circular saw blade welding and Carbide Tip Brazing Machine,Please contact us if you need it

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.