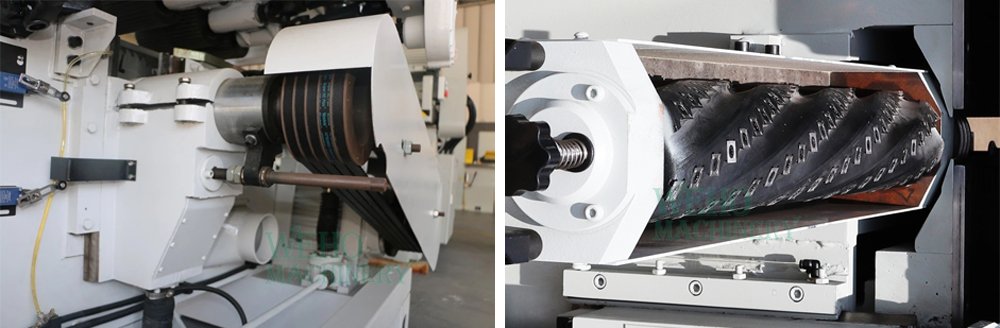

• Fast knife replacement

• Fast and convenient belt tension adjustment.

• Automatic lubricator

Automatic wood thickness double surface planer

Automatic wood thickness double surface planer

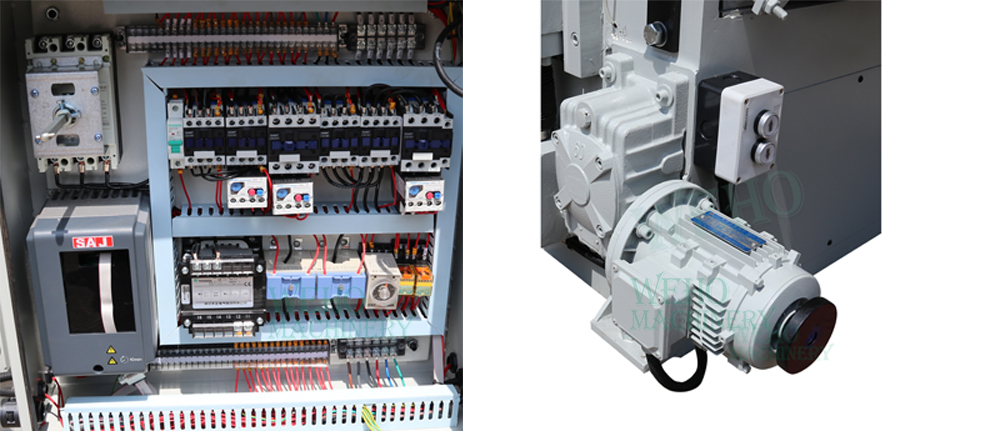

| Model | MB610 |

| Max. working width | 610mm |

| Max. working thickness | 150mm |

| Min. working thickness | 14mm |

| Min. working length | 320mm |

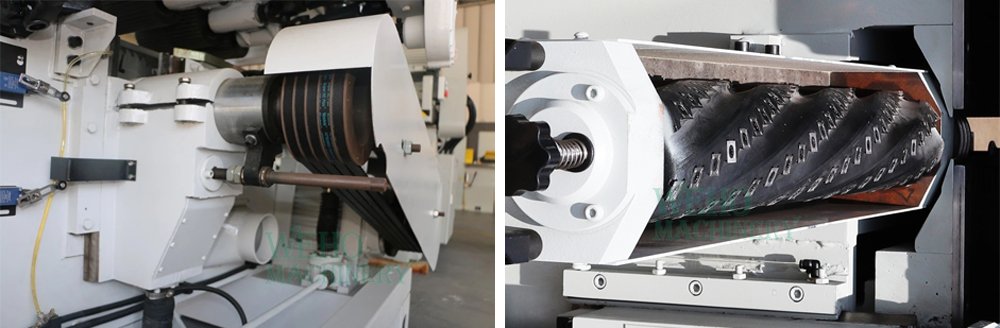

| Cutter quantity | 3pcs |

| Spindle rotating speed | 4500r/min |

| Feeding speed | 7-16m/min |

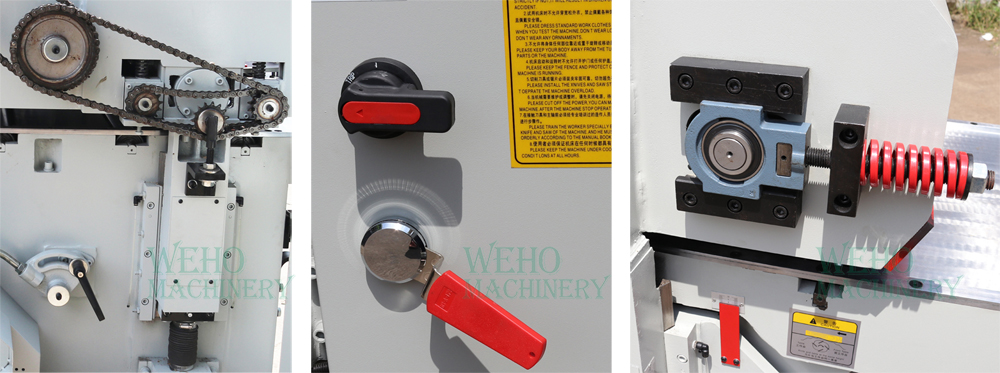

| Top spindle power | 11kw |

| Bottom spindle power | 7.5kw |

| Feeding motor power | 2.2kw |

| Elevating motor power | 0.37kw |

| Total power | 21.07kw |

| Overall size | 2350*1268*1680mm |

Automatic wood thickness double surface planer

Automatic wood thickness double surface planer

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.