- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

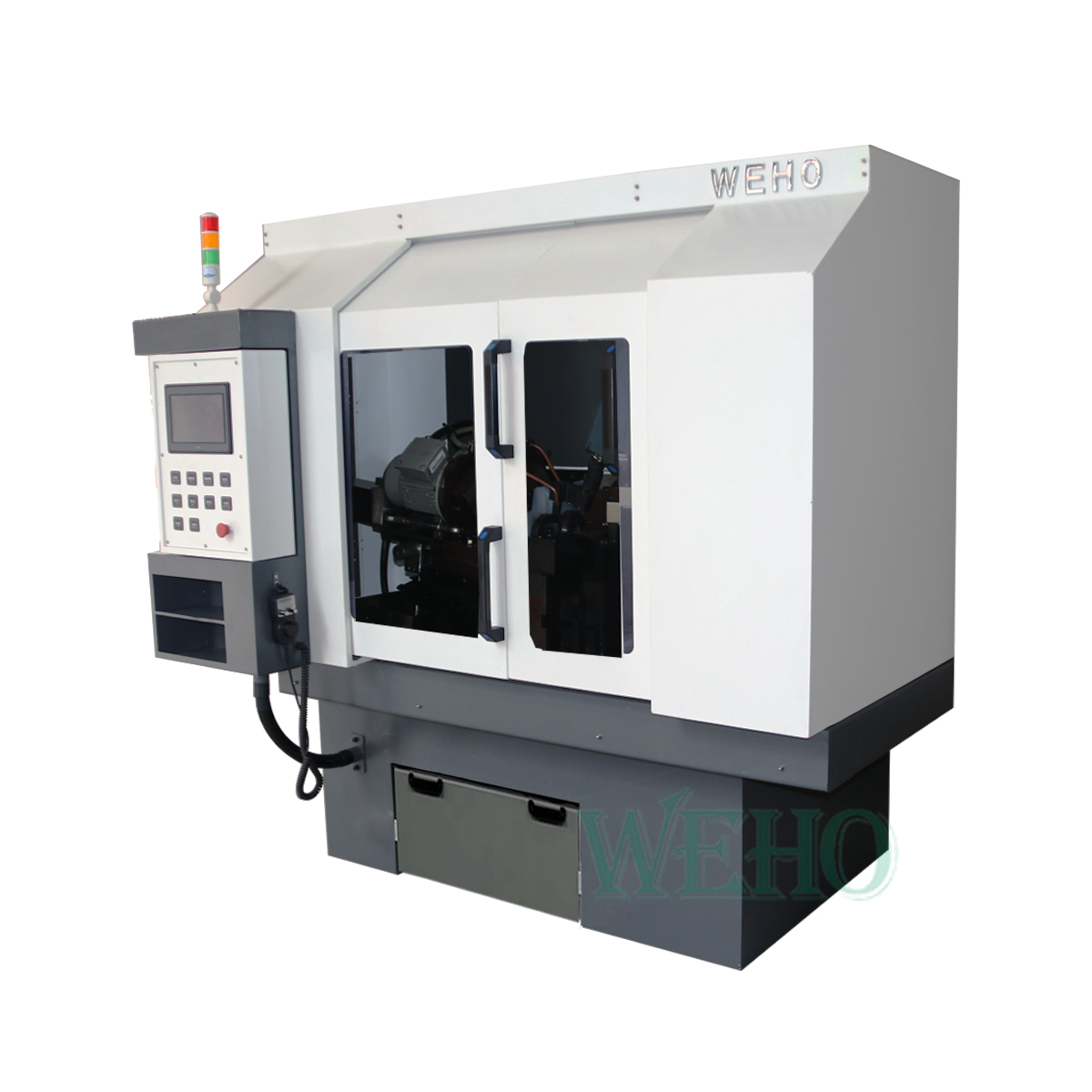

Automatic dual double flank side grinder TCT circular carbide teeth saw blade grinding machine

- Model:MF-D110

Max thickness: 12mm

Tooth pitch:7-70mm

Radial angle:-15°~30°

Maxmum grinding stroke:20mm - Grinding wheel linear speed:28m/s, 35m/s

- Water pump flow:24L/min

Total power:3.8KW

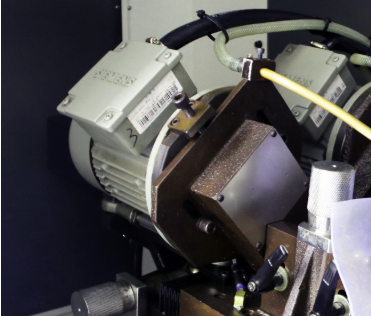

It's designed specially for side grinding the teeth of circular saw blades. Double Side Grinder features two Siemens grinding motors.The aim is to provide a clean and an undamaged cutting edge for the materials used.

| Model | MF-D110 |

| Circle saw outside dia | φ100-900mm |

| Bore dia | φ12-105mm |

| Max thickness | 12mm |

| Tooth pitch | 7-70mm |

| Radial angle | -15°~30° |

| Tangential angle | -4°~6° |

| Maxmum grinding stroke | 20mm |

| Grinding speed | 0.5-7mm/s |

| Grinding wheels outside dia | φ80,φ100,φ125mm |

| Grinding wheel linear speed | 28m/s, 35m/s |

| Water pump flow | 24L/min |

| Content of coolant pump | 90L |

| Voltage | 3PH/380V |

| Total power | 3.8KW |

| Equipment size | 1950*1550*1950mm |

| Packing size | 2150*1750*2350mm |

| Total weight | 1500kg |

Main Features

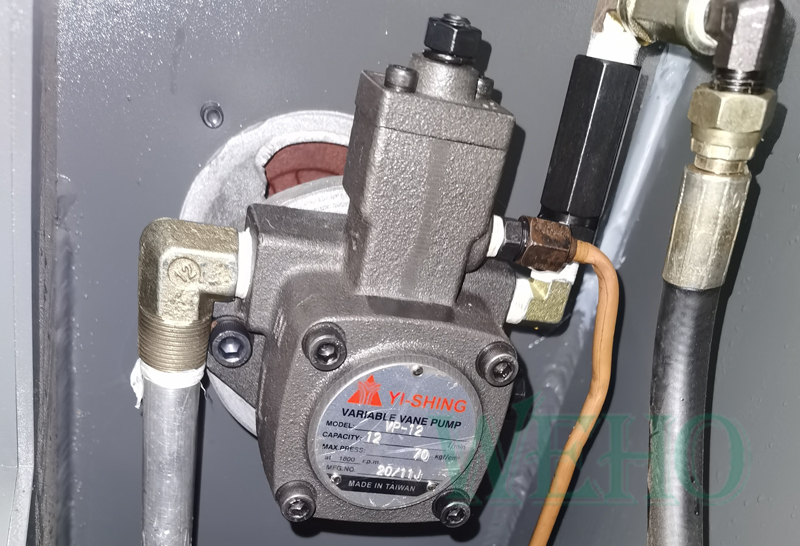

Hydraulic driven.

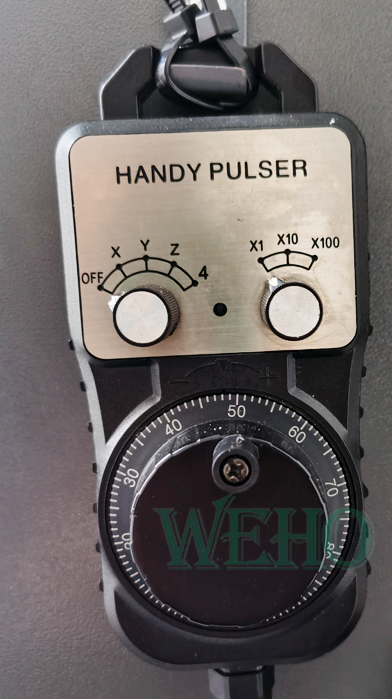

Microprocessor controlled.

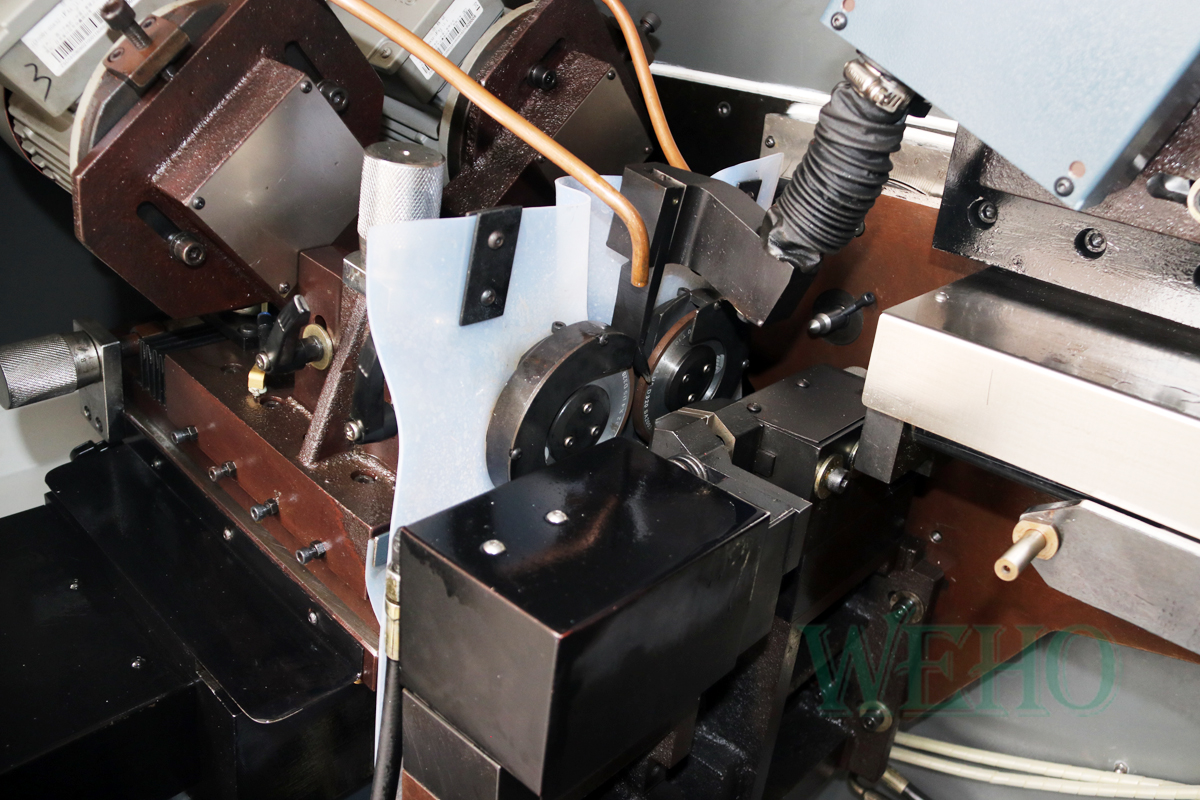

Independently adjustable grinding heads.

Quick setup of blade thickness, tangential clearance and radial clearance angles.

Linear bearing slide system.

Variable grinding feed rate Hydraulic saw blade clamp

Enclosed cabin for operator safety.

Simple controls for ease of use. Ergonomic cabin.

Production conformed with CE standards.

The machine has automatic compensation program to compensate.It can adjust grinding speed and it has automatic lubrication system.

Automatic tct circular saw blade Dual Side grinding machine carbide teeth double flank side grinder

Grinding wheels main spindle

circular saw blade Dual Side grinding machine carbide teeth double flank side grinder

circular saw blade Dual Side grinding machine carbide teeth double flank side grinder

Double side grinding wheels.Saw blade holders in variant sizes.Taiwan spindle with has 18 months warranty.

Inovance servo system or Delta servo system,Siemens grinding motor

How to buy

1. Contact WEHO sales and provide your requirents to get best solutions

2. Order confirmed, get invoice, contract from WEHO.

3. Normally, producton started against TT by 30% deposit.

4. After one week, WEHO sales inform you production state and delivery date.

5. Order finished, WEHO sales send you photos, videos and spare parts for confirmation.

6. Book shipping order, delivery the machine to your port.

How to do if I can not operate

When you get the machine, if you have operation problem, we will make video meeting to teach you. If video teaching can not solve, our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for weho machines, including find problems, send spart parts, and teach you to replace the parts.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.