- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

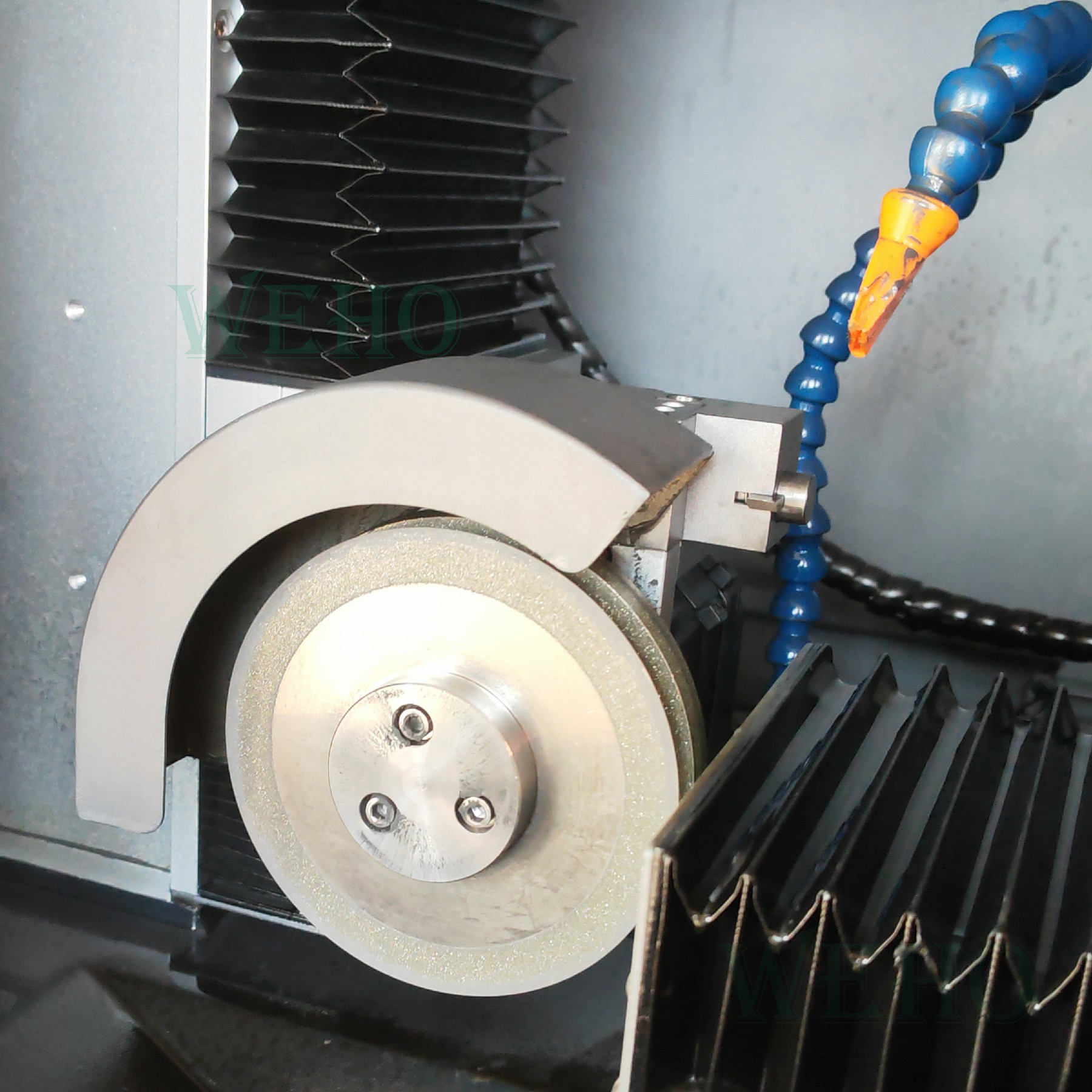

Automatic CNC Dust Free Tool Grinder for 2-4 Blades Milling Cutter Sharpening Machine with 4-20mm grinding diameter

Model: YM30

Applicable tool diameter: 4-20mm

Gross pawer: 1.8KW

Grinding wheel speed: 3000/ min

Grinding time: 2 min/branch

Grinding wheel life: φ6mm-8mm/800-1000 pieces

|

Applicable tool diameter |

4-20mm |

|

Applicabie number ofmilling cutter blades |

2 blade, 3 blade, 4 blade flat miling cutter |

|

2 blade, 4 blade round nose knife |

|

|

2 blade tungsten steel drill bit |

|

|

2 blade ball knife |

|

|

Gross pawer |

1.8KW |

|

Grinding wheel speed |

3000/ min |

|

Grinding time |

2 min/branch |

|

Grinding wheel life |

φ6mm-8mm/800-1000 pieces |

|

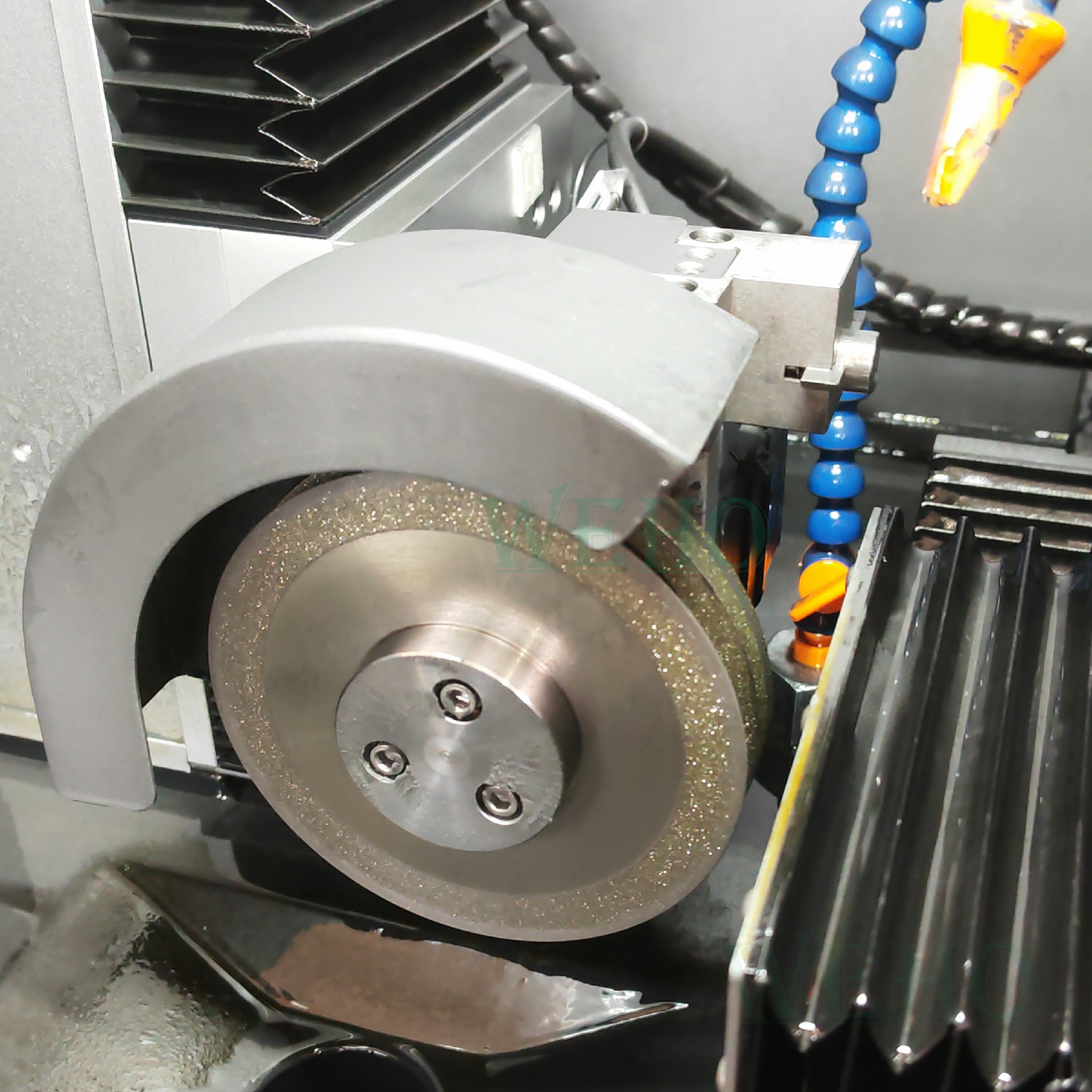

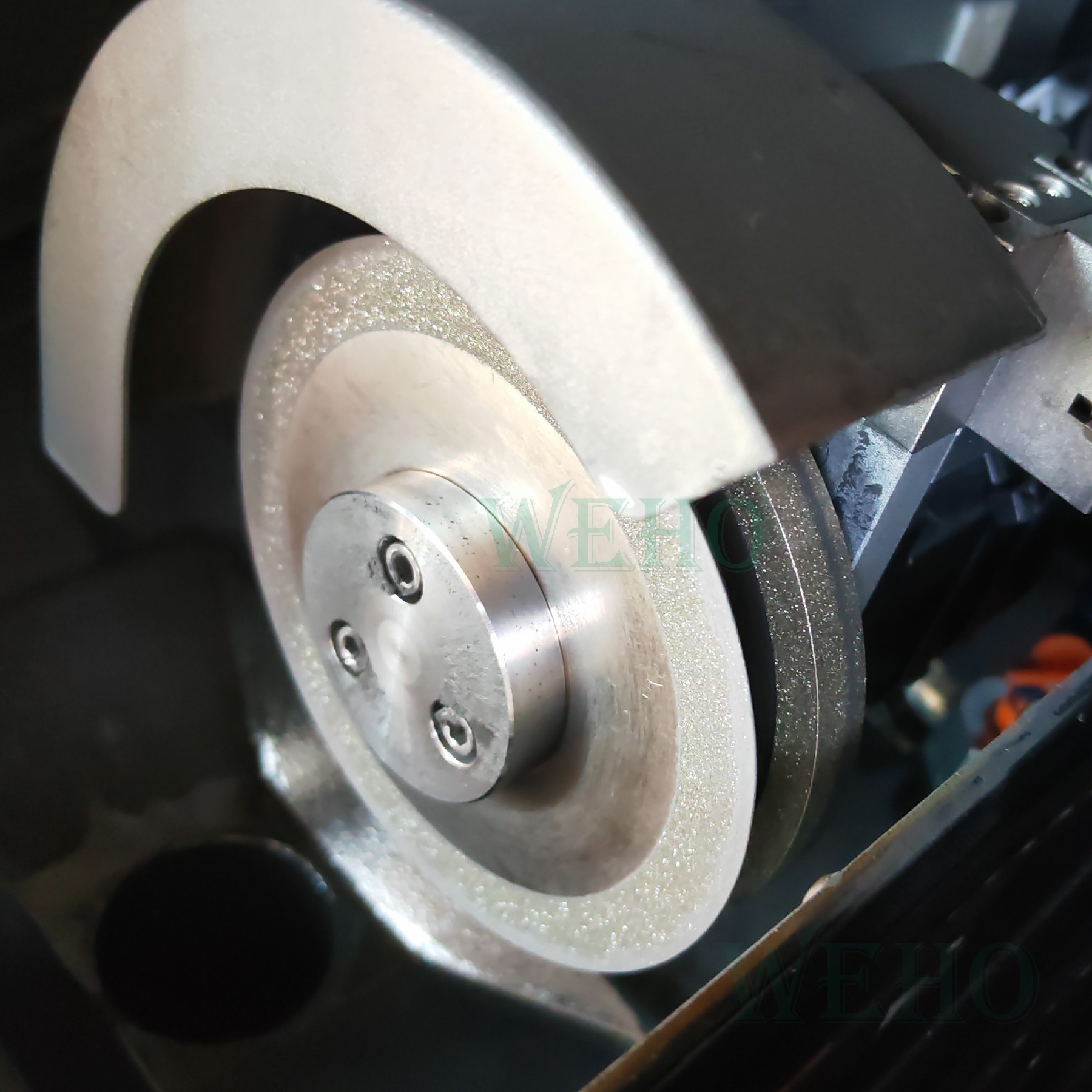

Grinding wheel material |

Diamond |

|

Overall dimension |

L120 x W80 x H160cm |

|

Net weight of equipment |

180KG |

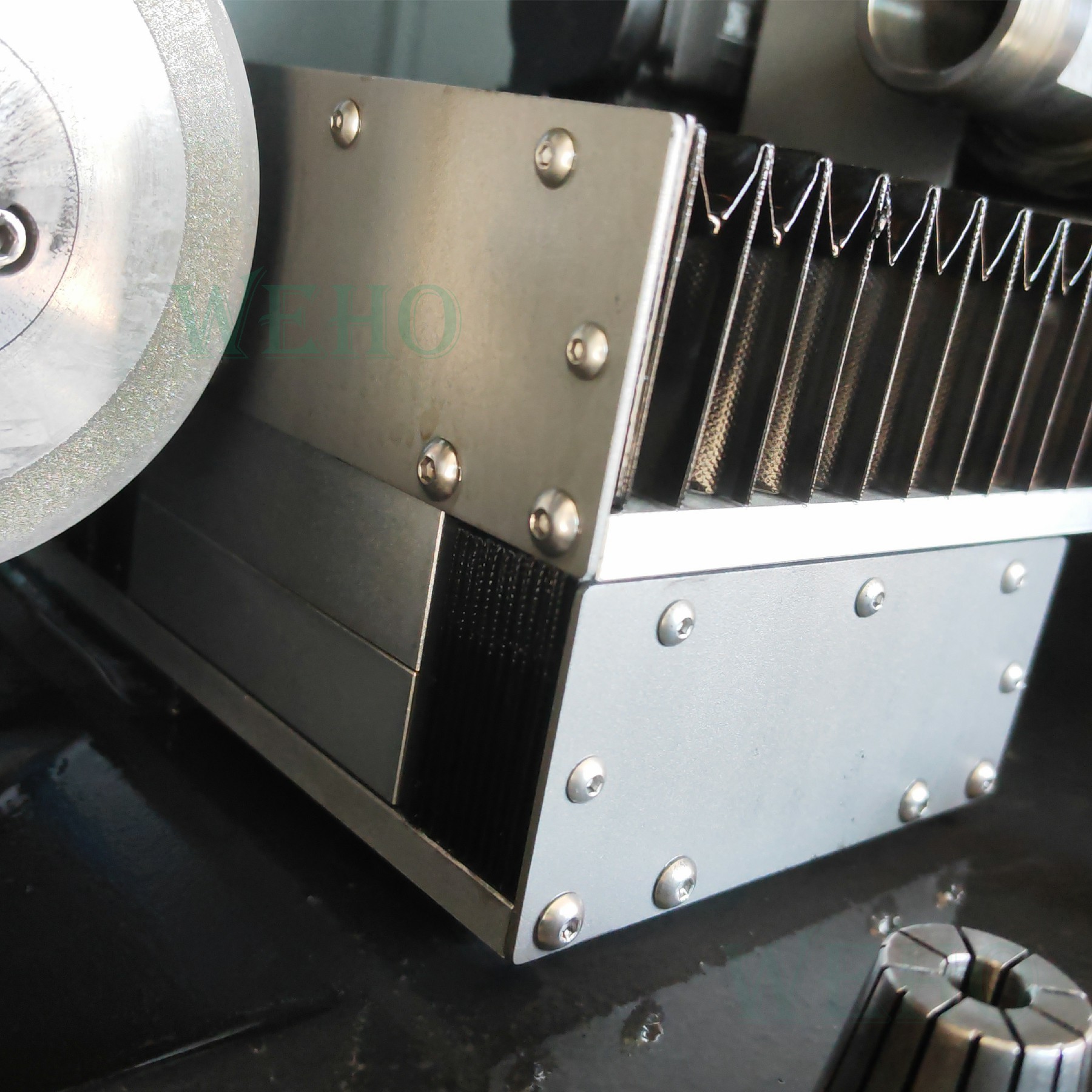

1. The overall bed adopts an internal hidden gantry bracket design, which has strong overall rigidity. Compared with similar machines, it has strong stability and better rigidity.

2. Circuit board installed vertically to avoid dust and water droplets directly accumulating on the circuit board, which may cause a short circuit in the machine. The back of the machine opens the door for easy maintenance.

3. Guide rail screws are all made of first-line brands, further ensuring the accuracy and service life of the equipment operation. Especially when grinding round nose knives and drill bits, the difference is obvious.

4. All X, Y, and Z axis fixed positions have pin positioning to ensure equipment assembly accuracy and rigidity.

5. Milling cutter installation shaft, middle through-hole, which can grind longer cutting tools. The milling cutter clamping shaft and the grinding wheel clamping shaft are all precision ground and smoothly matched by grinder. Further ensure the concentricity of the milling cutter shaft and minimize the positional deviation caused by replacing the grinding wheel.

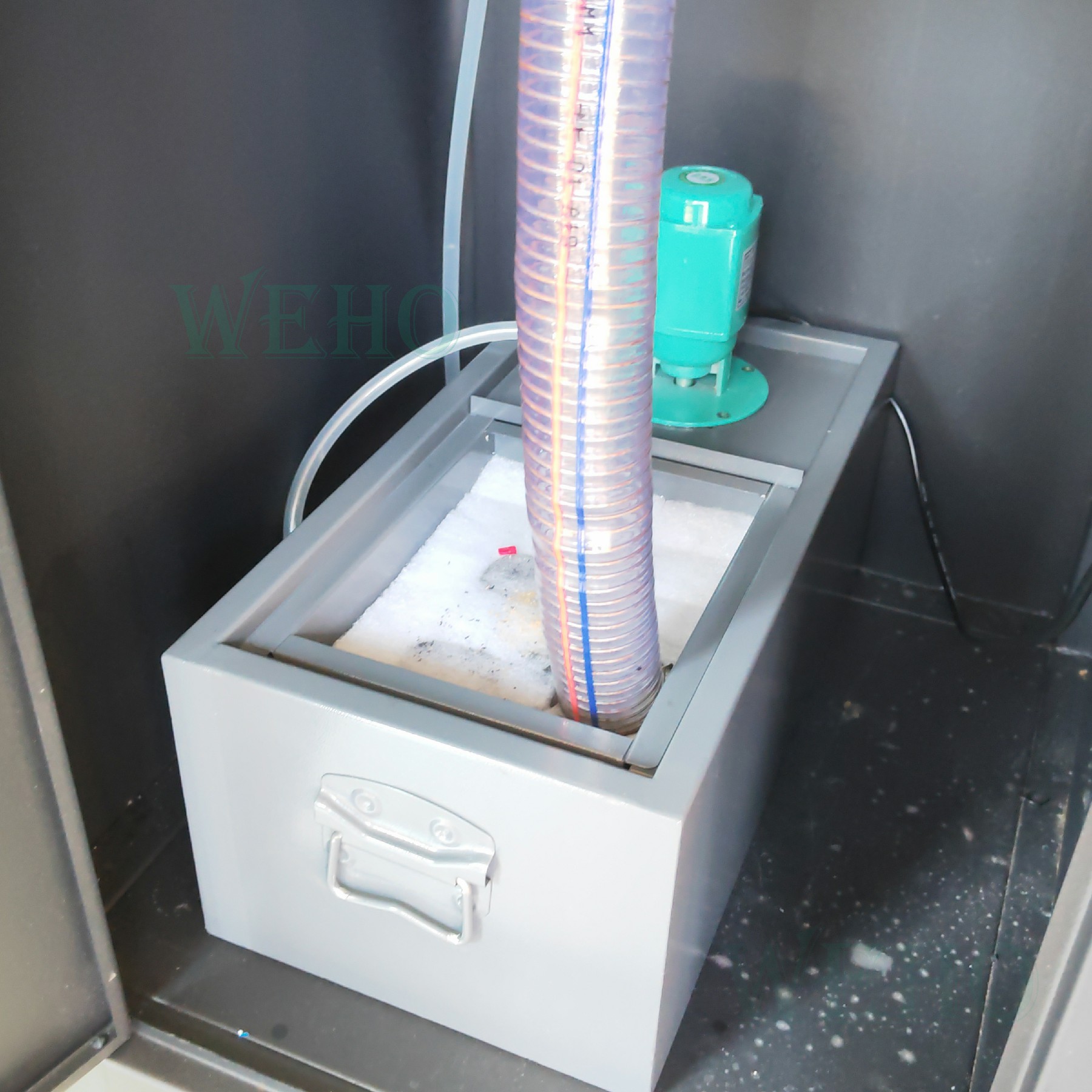

6. Equipment has built-in dust removal function, which can effectively handle the dust generated during tool grinding and collect it into the filter element. The dust collection filter element is designed with stainless steel and can be repeatedly cleaned and used. When cleaning, air guns or water can be used. After washing, there is no need to air dry, and it can be installed and used directly.

7. Internal 24V power supply, using the best domestic first-line brands. The power switch adopts a load switch to protect the equipment. The power cord connection adopts aviation plugs, which are stable and durable.

Equipment control program

1. Entire control program is completely independently developed, with a simple and easy to understand operating interface. Round nose knife and ball knife both have diameter compensation function.

2. Have 4 languages can choose: Chinese, English, Russian, Vietnamese, and other languages can be customized.

How to buy

1. Contact WEHO sales and provide your requirents to get best solutions

2. Order confirmed, get invoice, contract from WEHO.

3. Normally, producton started against TT by 30% deposit.

4. After one week, WEHO sales inform you production state and delivery date.

5. Order finished, WEHO sales send you photos, videos and spare parts for confirmation.

6. Book shipping order, delivery the machine to your port.

How to do if I can not operate

When you get the machine, if you have operation problem, we will make video meeting to teach you. If video teaching can not solve, our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for weho machines, including find problems, send spart parts, and teach you to replace the parts.

Service contacting

Before buying, choose suitable model contact Whatsapp 008613378477841. After buying, technical supporting contact 008613326792205

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.