- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

Automatic 6 side wood hole square machine for drilling holes in wood | Wood Boring Machine

Modle:CNC6025

Vacuum pump power:7.5kw

Total power:20kw

Spindle power:6.0kw

Spindle speed:18000r/min

Vacuum pump power:7.5kw

Total power:20kw

Spindle power:6.0kw

Spindle speed:18000r/min

Details

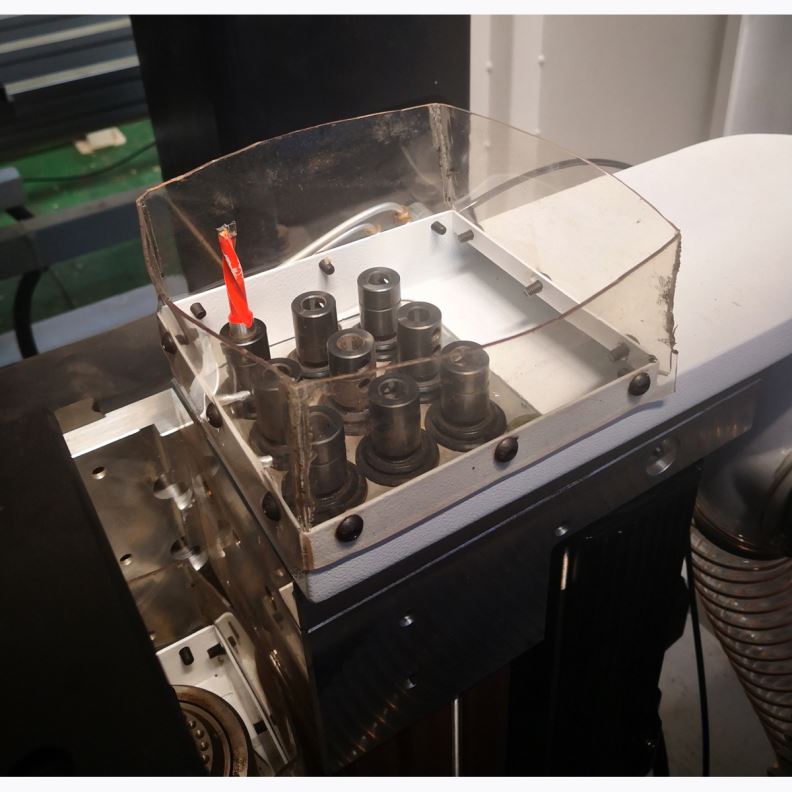

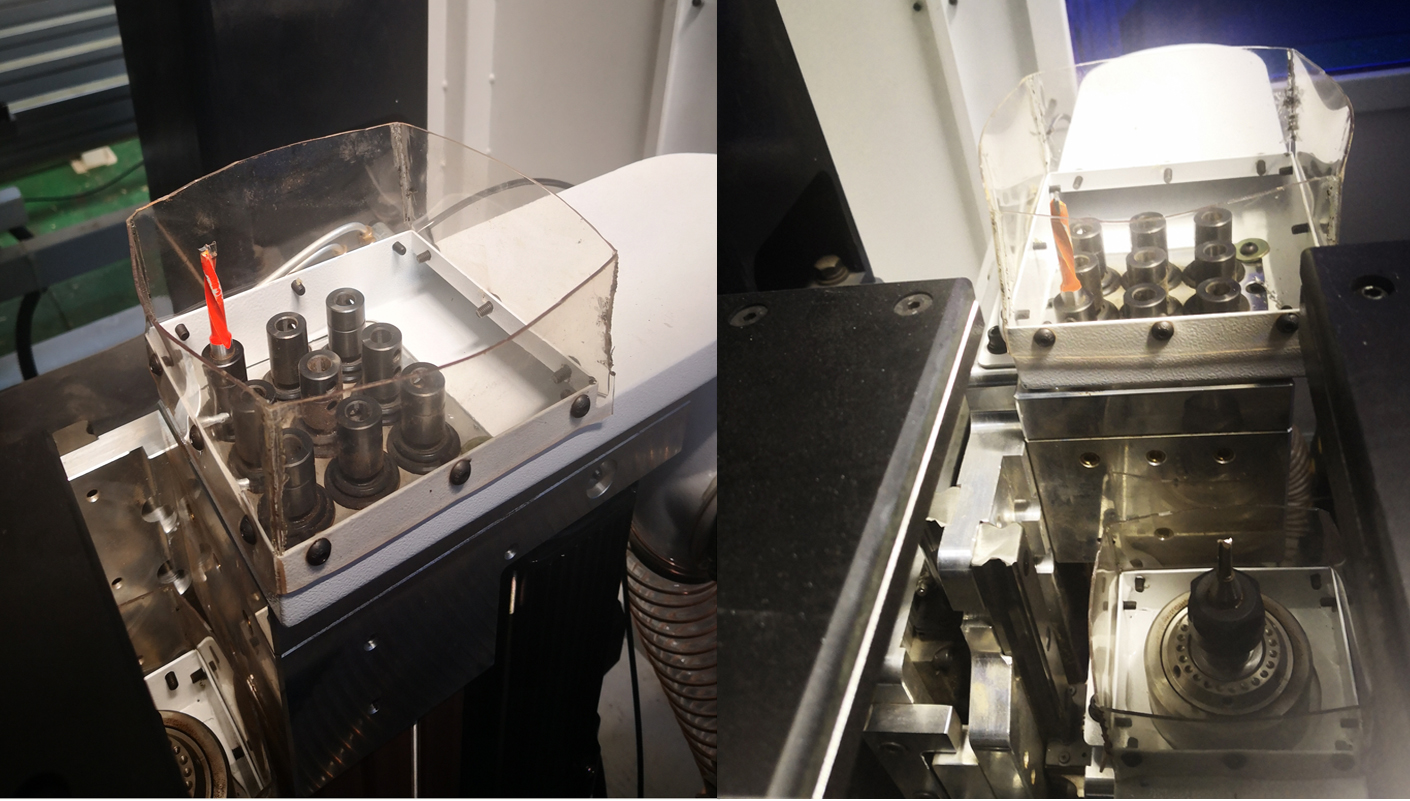

Spare Parts

Inquiry

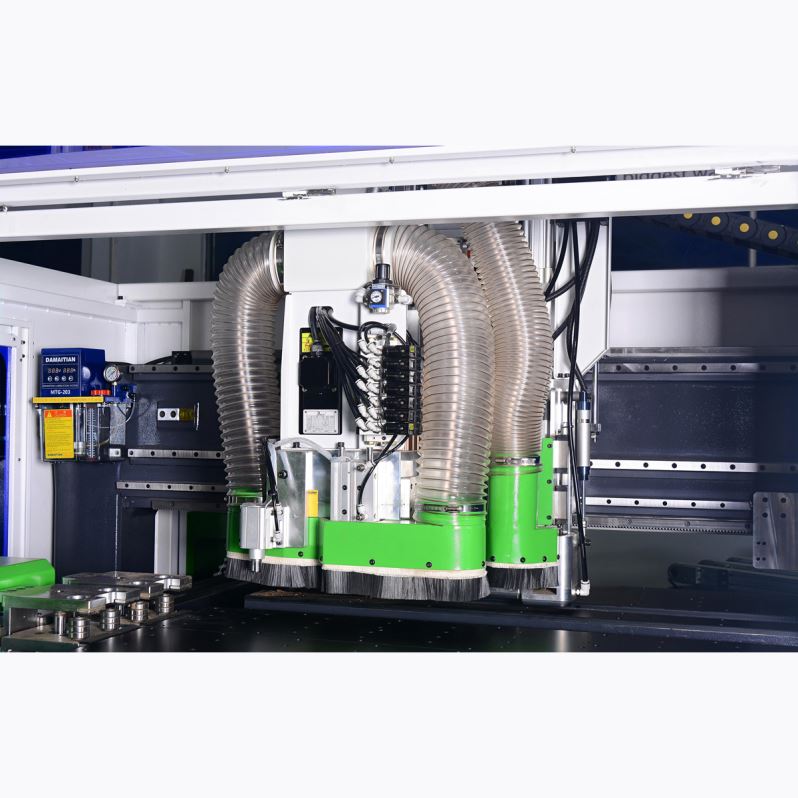

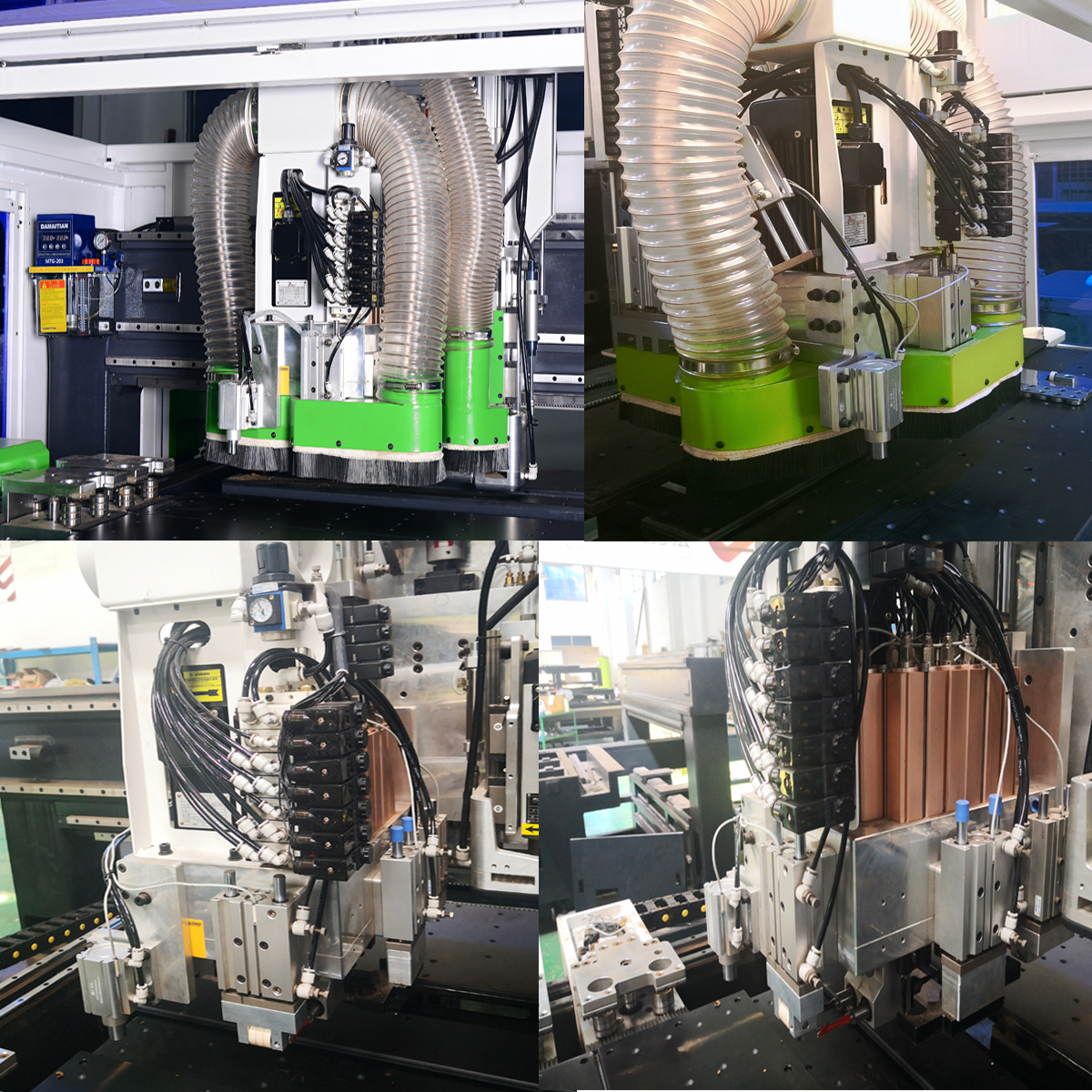

Six-sided processing,complete six sides processing and slotting and milling at one time; easy to operate, flexible to use, and free from manual intervention.

Designed with vertical pressure roller to ensure the machining accuracy of vertical hole and slotting 6 side wood boring machine.

Manufactured with upper and lower spindles, so there is no need to turn the plate for forward and reverse slotting.

Manufactured with upper and lower spindles, so there is no need to turn the plate for forward and reverse slotting.

| Processing size | 2460*1240mm |

| Spindle power | 6.0kw |

| Spindle speed | 18000r/min |

| Traveling speed | >25m/min |

| Material processing speed | 8-12m/min |

| Vacuum pump water tank | Stainless steel |

| Vacuum pump power | 7.5kw |

| Total power | 20kw |

| Machine size | 3800*2600*2400mm |

| Weight | 2500kg |

cnc 6 side boring machine Features :

1.Quickly and accurately,can drill multi kinds of hole and there is no limit to the board width.

2.Specially developed for horizontal perforater plate custom furniture.

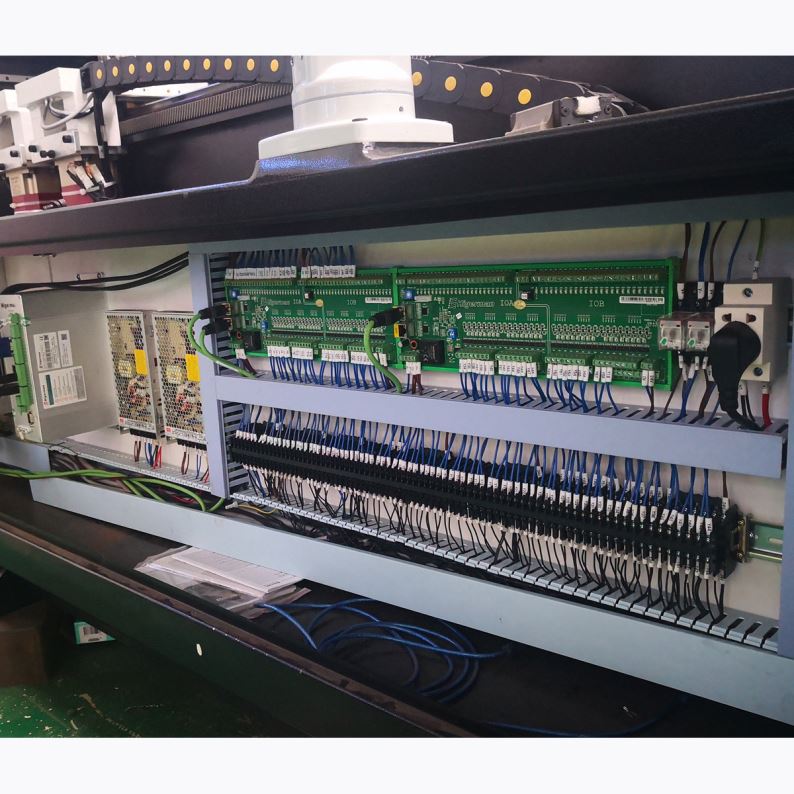

3.Drive motor adopts servo motor equipped with reducer easily ensure machine run fast and smooth.

1.Quickly and accurately,can drill multi kinds of hole and there is no limit to the board width.

2.Specially developed for horizontal perforater plate custom furniture.

3.Drive motor adopts servo motor equipped with reducer easily ensure machine run fast and smooth.

furniture cnc boring machine,cantilever operator interface.

cnc 6 side boring machine save time, save human labour , high efficiency , the tolerance of the hole is very small .

Precision machining with CNC gantry machining center.

Rack structure: heavy bed, precision welding, laser cutting, rack bed, high temperature tempering,

aging treatment, remove internal stress, enhance rigidity and ensure the stability of the bed.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.