- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

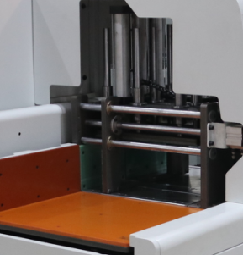

Aluminum Profile Cutting Machine Without Tailings

Max cutting size W×L: 320×100mm

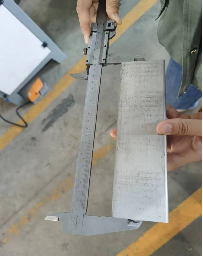

Cutting length precision: ±0.1mm

Saw blade size: Φ455×Φ30mm×4.0×120T

Overall size L×W×H: 2450*1700*1600mm

Machine weight: 750KG

| Model | MJL455E |

|

Max cutting size W×L |

320×100mm |

|

Feeding mode |

Servo feeding material |

|

Saw blade feeding mode |

Servo feeding blade |

|

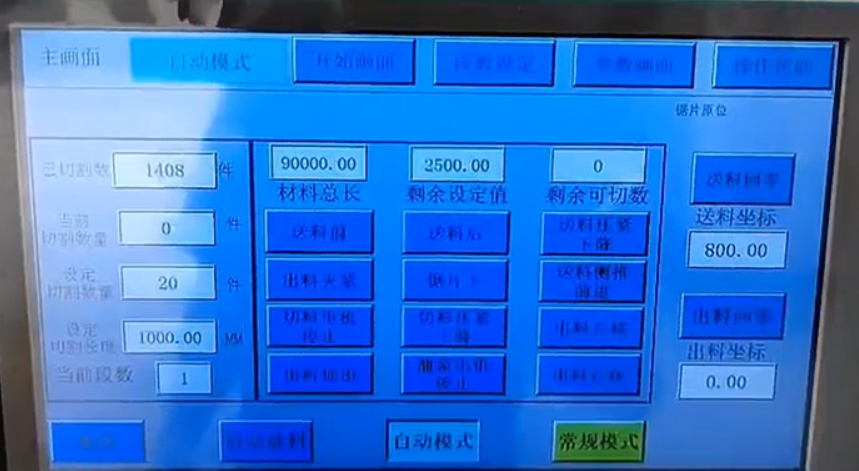

Control |

PLC touch screen |

|

Max feeding length one time |

1000mm(bigger length by several times feeding) |

|

Cutting length precision |

±0.1mm |

|

Main motor |

4KW |

|

Feeding servo motor |

1.0KW |

|

Feeding in and out servo motor |

0.75KW |

|

Saw blade size |

Φ455×Φ30mm×4.0×120T |

|

Voltage |

380V / 3ph,5 wires |

|

Overall size L×W×H |

2450*1700*1600mm |

|

Machine weight |

750KG |

Stable cutting speed ensures cutting accuracy

The operation interface is simple, the operation is simple, and the performance is stable

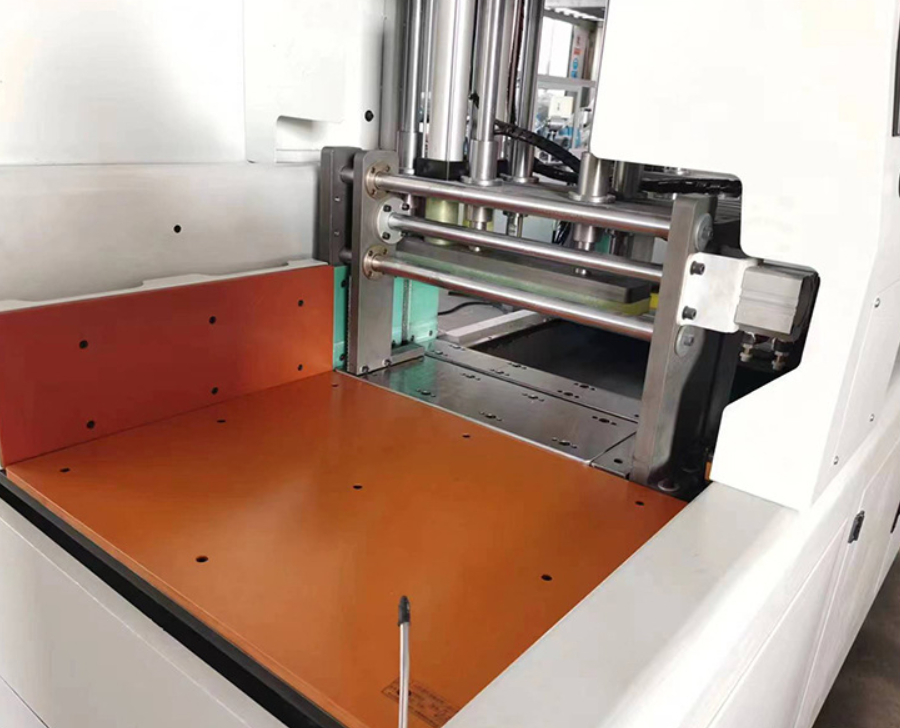

Cutting without tailings, with anti pull material surface design

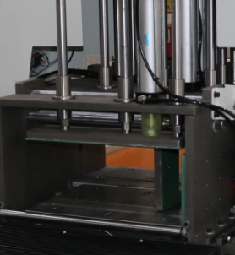

Automatically spray atomized cutting fluid to cool and lubricate the saw blade during sawing, timely discharge the powder between the teeth, and extend the service life of the saw blade

The upper, lower, front, and back use cylinder clamping materials, which will not loosen during sawing, ensuring accurate sawing angles.

The cylinder is equipped with a pressure regulating valve to ensure that the hollow material does not deform.

Update Aluminium Profile cutting

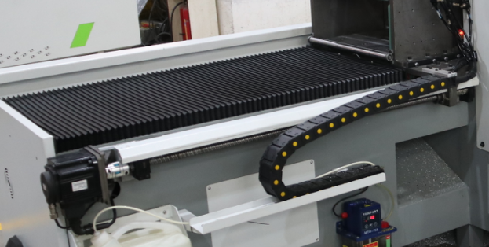

Change the manual feeding to the Servo automatic feeding.

Cutting width setting by sensor control, change to Servo automatic control.

Ruler or digital positioning, change to servo positioning;

Pre clamping work pieces;

Optimize tailless materials.

Problems solved by MJE455

1. Low cutting efficiency

2. Low cutting accuracy

3. The surface of the material is prone to scratching

4. Frequent replacement of pads is required

5. After cutting, when retracting the blade, the saw blade scrapes the material

6. Tail material too long

|

Product parts configuration |

|

|

Air cylinder,Air pressure regulation, solenoid valve |

AirTAC/ Delixi |

|

PLC |

Taiwan Shilin |

|

Linear guide screw |

Hiwin or TBI |

|

Touch screen |

Taiwan Shilin |

|

Servo motor |

HCFA(Hechuan) |

|

Sensor switch |

Sendingrui |

|

Motor |

Hanlin |

|

Low voltage electric part |

Delixi |

Content:

● The current situation of aluminum profile cutting in the market.

● How to intelligently upgrade the cutting process.

● MJ455E performance.

● Comparison of equipment cost input, output, and cost savings

Current situation of aluminum profile cutting A

At present, aluminum profile cutting is mainly by semi-automatic machine, using relatively simple cylinders or hydraulic cylinders to push the saw blade for cutting .

The work piece is manually pushed for feeding. The cutting size is mostly determined by ruler positioning or digital positioning.

Current situation of aluminum profile cutting B

The advance of aluminum profile cutting is to win by quantity and quality, which determines that only automated equipment can produce more products per unit of time.

With the current aluminum profile cutting equipment on the market, relying too much on manual labor, cutting speed is too slow, cutting length positioning error is large, and the accuracy of the resulting products is not high.

There is another problem with some highly automated equipments, which is the waste caused by excessively long tailings.

Over time, although automation equipment has been installed, the cost has not actually decreased.

How to buy

1. Contact WEHO sales and provide your requirents to get best solutions

2. Order confirmed, get invoice, contract from WEHO.

3. Normally, producton started against TT by 30% deposit.

4. After one week, WEHO sales inform you production state and delivery date.

5. Order finished, WEHO sales send you photos, videos and spare parts for confirmation.

6. Book shipping order, delivery the machine to your port.

How to do if I can not operate

When you get the machine, if you have operation problem, we will make video meeting to teach you. If video teaching can not solve, our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for weho machines, including find problems, send spart parts, and teach you to replace the parts.

Service contacting

Before buying, choose suitable model contact Whatsapp 008613378477841. After buying, technical supporting contact 008613326792205

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.