A woodworking spindle moulder, also known as a spindle shaper, is a machine tool used in woodworking to shape and profile wood. It is a vital piece of equipment in many woodworking shops, especially those that specialize in furniture, cabinetry, and other intricate woodwork. This article will delve into the functions, components, types, and applications of spindle moulders, providing a comprehensive overview for both novice and experienced woodworkers.

Understanding the Spindle Moulder

Definition and Purpose

A spindle moulder is designed to shape wood by rotating a cutter head at high speeds. The wood is fed into the machine and brought into contact with the rotating cutter, allowing for accurate shaping of edges, profiles, and grooves. This tool is particularly useful for producing decorative edges and complex profiles that would be difficult to achieve with hand tools.

Key Components

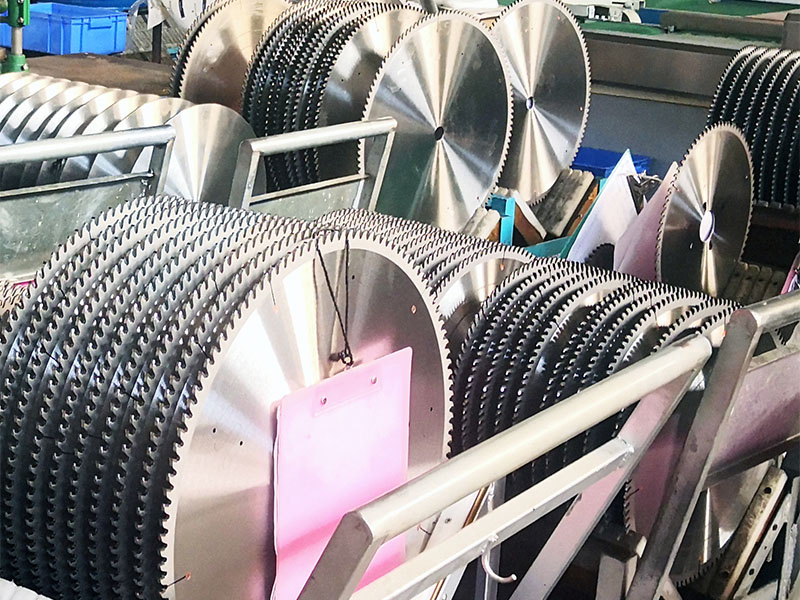

Cutter Head: The cutter head is the heart of the spindle moulder. It holds the cutting tools and rotates at high speeds to shape the wood. Cutter heads can be changed to suit various profiles and forms.

Spindle: The spindle is the shaft that holds the cutter head. It can be adjusted vertically and horizontally to accommodate different thicknesses and widths of wood.

Table: The table provides a flat, stable surface for the wood to rest on while being shaped. Many spindle moulders have adjustable tables to accommodate different sizes of workpieces.

Fence: The fence directs the wood as it enters the machine, resulting in uniform and accurate cuts. It can be adjusted to different angles and positions to facilitate various shaping tasks.

Feed Mechanism: Some spindle moulders come with an integrated feed mechanism, which automatically moves the wood through the machine at a controlled speed.

Types of Spindle Moulders

Spindle moulders can be categorized based on their design and functionality:

Single Spindle Moulders

These are the most common type of spindle moulders, featuring a single rotating spindle. They are versatile and suitable for a wide range of woodworking tasks, from simple edge profiling to more complex shapes.

Double Spindle Moulders

Double spindle moulders have two spindles, allowing for simultaneous shaping operations. This type is very beneficial in high-volume manufacturing environments since it can improve efficiency and shorten production times.

Vertical Spindle Moulders

In vertical spindle moulders, the spindle is oriented vertically. This design is ideal for shaping larger workpieces and allows for greater control over the shaping process.

Horizontal Spindle Moulders

Horizontal spindle moulders feature a horizontally oriented spindle. They are commonly used to create flat surfaces and are especially useful for edge profiling.

Applications Of Spindle Moulders

Spindle moulders are used in various woodworking applications, including:

Furniture Making

In furniture manufacturing, spindle moulders are crucial for shaping components such as cabinet doors, table edges, and chair parts. They allow woodworkers to create intricate profiles that enhance the aesthetic appeal of the furniture.

Cabinetry

Spindle moulders are widely used in cabinetry for producing custom mouldings, drawer fronts, and joints. They allow you to create crown mouldings and baseboards that add character to cabinets, as well as shape drawer fronts to match the overall design. Additionally, spindle moulders can cut rebates and dadoes, which are essential for securely joining cabinet components.

Moulding and Millwork

In the production of moulding and millwork, spindle moulders excel at creating decorative trims, such as crown and base mouldings, as well as window and door casings. These machines can produce intricate profiles that enhance the visual appeal of architectural elements, contributing to the overall aesthetic of a space.

Joinery

Spindle moulders are invaluable in joinery, where they are used to create tenons and finger joints.

These joints are vital for providing strong connections between pieces of wood, which is required for the longevity of furniture and cabinetry. The precision offered by spindle moulders ensures that these joints fit tightly, enhancing the structural integrity of the final product.

Architectural Woodwork

In architectural woodwork, spindle moulders are used to produce custom profiles and decorative elements. They can create unique designs for corbels, brackets, and other architectural details, allowing for a high level of customization in building projects.

Production of Wooden Components

Spindle moulders are also employed in the mass production of various wooden components, including shutters, window frames, and doors. Their efficiency ensures constant quality over large quantities, making them perfect for manufacturing applications where precision and speed are critical.

Artistic Woodworking

For artists and craftsmen focused on unique projects, spindle moulders provide the flexibility to create intricate designs and custom furniture pieces. The capacity to form wood into intricate profiles fosters creativity, allowing woodworkers to realize their artistic ambitions.

Conclusion

A woodworking spindle moulder is an invaluable tool for any serious woodworker.

Its ability to shape wood with precision and efficiency makes it a staple in woodworking shops. Whether for professional or hobbyist projects, mastering the spindle moulder can lead to improved workmanship and inventiveness in woodworking.

.jpg)

.jpg)

.jpg)