Understanding of Wood Turning Machine

Overview In 6000 BC, the Palestinians made bow saws. The pyramids built in Egypt in 2700 BC contained hand-drawn copper saws and hand-pushed copper planes, reflecting the first stage of wood cutting technology characterized by manual operations. After the European industrial revolution at the end of the 18th century, machine tools and tools for wood cutting began to appear and developed. This process continued until the beginning of the 20th century. Wood cutting machine tools became more and more sophisticated, the hardness of the tools increased, and the cutting speed increased. The problem of the reduction of cutting quality caused by severe damage to the tools in the production of wood-based panels and tropical wood was solved. This marked the second stage characterized by the mechanization of wood cutting. Since the 1960s, electronic technology and computing technology have been applied to wood cutting, which not only improved the level of wood cutting technology, but also provided reliable testing methods and numerical analysis methods for the study of complex cutting mechanisms, thereby promoting the development of wood cutting. The third stage with automation as the main trend.

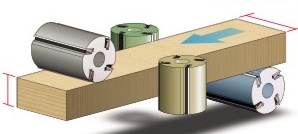

The relative movement of the wood by the tool acting on the wood to obtain a certain shape, size and surface state of the wood product processing process. It is a basic process that accounts for the largest proportion in wood processing, and its quality has an important influence on the gluing process and the surface decoration process. The mechanism of wood cutting involves the mechanical properties of wood, the material of the tool and its processing method and geometry, the relative movement of the tool and the wood processing part, the mechanism that realizes a certain movement, and the cutting force, etc., which have been the basis of production practice and scientific research. Form an independent discipline on top.

According to the formation of products and chips during the cutting process, wood cutting can be divided into three forms: ①The workpiece is cut off a layer of relatively deformed chips, and the rest are semi-products or products, such as planing, turning, etc.; ② Chips It is a product itself, such as veneer peeling, planing, etc.; ③The chips and the remaining workpieces are all products, such as milling used in chipping.

We provide Wood Turning Machine products. If you are interested in Wood Turning Machine, please contact us for more information.

The relative movement of the wood by the tool acting on the wood to obtain a certain shape, size and surface state of the wood product processing process. It is a basic process that accounts for the largest proportion in wood processing, and its quality has an important influence on the gluing process and the surface decoration process. The mechanism of wood cutting involves the mechanical properties of wood, the material of the tool and its processing method and geometry, the relative movement of the tool and the wood processing part, the mechanism that realizes a certain movement, and the cutting force, etc., which have been the basis of production practice and scientific research. Form an independent discipline on top.

According to the formation of products and chips during the cutting process, wood cutting can be divided into three forms: ①The workpiece is cut off a layer of relatively deformed chips, and the rest are semi-products or products, such as planing, turning, etc.; ② Chips It is a product itself, such as veneer peeling, planing, etc.; ③The chips and the remaining workpieces are all products, such as milling used in chipping.

We provide Wood Turning Machine products. If you are interested in Wood Turning Machine, please contact us for more information.