Spindle Shaper vs Router Table: Which is Right for Your Woodworking Projects?

In the world of woodworking, choosing the right tools can make a significant difference in the quality of your projects and your overall workshop experience. Among the most debated tools are the spindle shaper and the router table. Each has its own unique features, advantages, and ideal applications. This article will delve into both options, helping you decide which is best suited for your woodworking needs.

Understanding the Tools

What is a Spindle Shaper?

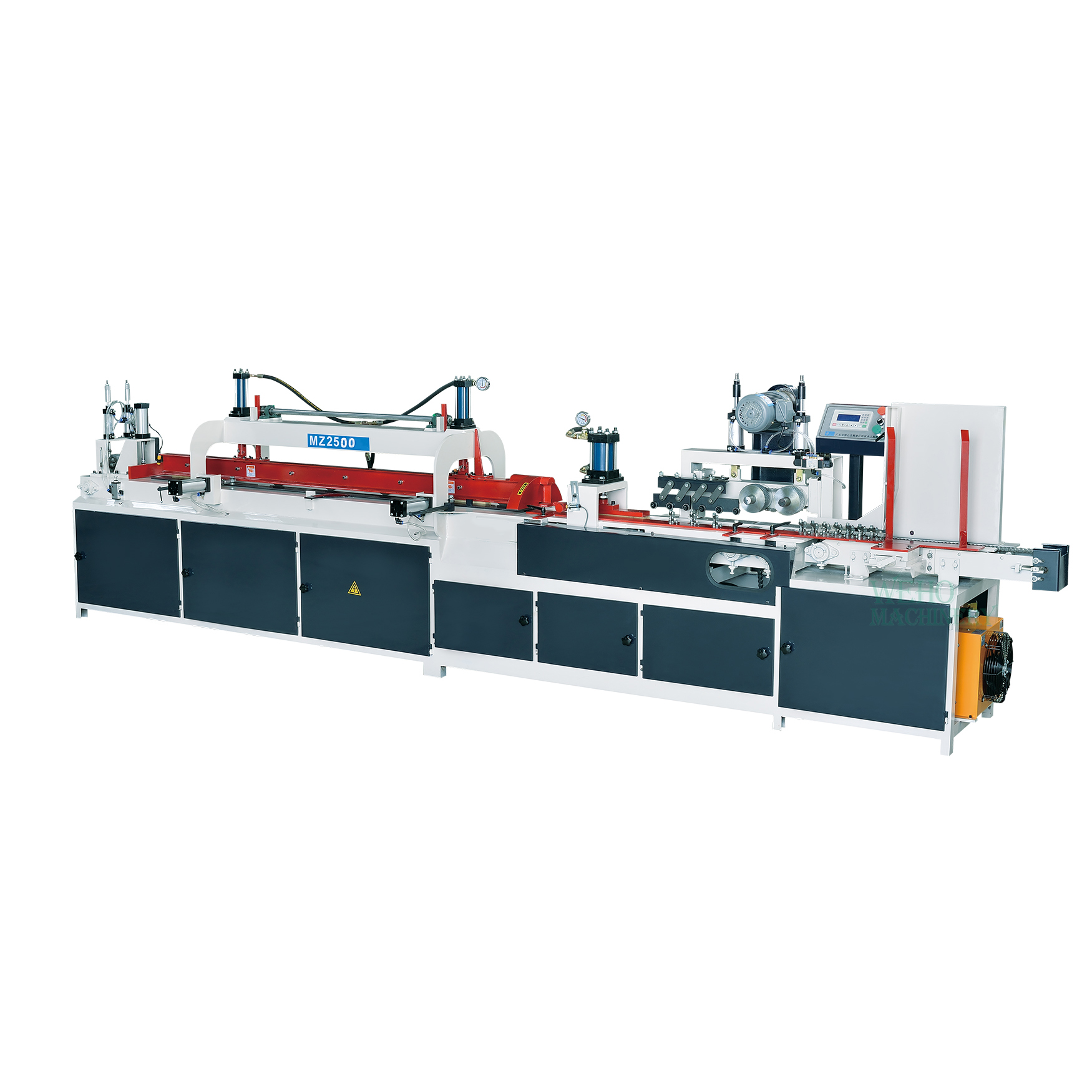

A spindle shaper, also known as a wood shaper or spindle moulder, is a stationary machine that utilizes a vertically oriented spindle to drive cutter heads. This tool is designed for milling profiles on wood stock, making it particularly effective for larger cuts and more complex shapes than those typically handled by routers. Spindle shapers usually have more powerful motors, ranging from 1.5 to 5 horsepower, allowing for deeper cuts in fewer passes.

What is a Router Table?

A router table consists of a flat surface with an inverted router mounted underneath. This setup allows woodworkers to guide their workpieces over the router bit with greater control and precision. Router tables come in various sizes and configurations, from portable benchtop models to larger, more stable floor-standing units.

Comparing Key Features

Power and Cutting Capacity

One of the most significant differences between spindle shapers and router tables is their power and cutting capacity. Spindle shapers are equipped with more powerful motors that can handle larger cutter heads, allowing them to make deeper cuts in a single pass. This capability makes them ideal for tasks such as creating crown moldings or raised-panel doors.

In contrast, router tables are generally better suited for smaller profiles and detailed work. While they can perform a wide range of tasks, they may require multiple passes to achieve similar results as a spindle shaper for larger cuts.

Speed

Router tables operate at much higher speeds than spindle shapers, typically ranging from 18,000 to 25,000 RPM. This high speed is advantageous for fine detail work but can lead to faster wear on bits if not used correctly. Spindle shapers typically run at lower speeds (3,000 to 10,000 RPM), which allows for smoother cuts with less vibration, resulting in cleaner finishes.

Versatility

Router tables are known for their versatility; they can accommodate various bits and attachments, making them suitable for edge profiling, groove cutting, and decorative work. Accessories like featherboards and miter gauges enhance control and safety during operation. Conversely, spindle shapers excel at specific tasks but may not offer the same range of applications as router tables.

Setup Time

Setting up a spindle shaper can be more time-consuming due to its complexity compared to the relatively straightforward setup of a router table. If you frequently switch between different types of projects or need quick adjustments, this factor may influence your decision.

Cost Considerations

While spindle shapers often require a higher initial investment, they can be more economical in the long run for serious woodworkers who frequently tackle large projects or specialized cuts. Router tables may seem less expensive initially but can accumulate costs as you upgrade components or purchase additional bits over time.

When to Choose Each Tool

Choosing a Spindle Shaper

Consider investing in a spindle shaper if:

- You regularly work on larger projects that require deep cuts or complex profiles.

- You prioritize smooth finishes with minimal sanding.

- You have space for a stationary machine in your workshop.

- You plan to invest in specialized tooling for unique woodworking tasks.

Choosing a Router Table

A router table might be the better choice if:

- You need versatility for various woodworking tasks.

- You work on smaller projects or detailed work where precision is crucial.

- You prefer quicker setups and adjustments between tasks.

- You're looking for a more economical option that allows gradual upgrades.

Safety Considerations

Both tools come with inherent risks associated with woodworking machinery but offer different safety features:

Spindle Shaper: Typically features guards above the cutter heads to protect hands from injury. The use of power feeders can enhance safety by keeping hands away from moving parts while maintaining consistent pressure on the workpiece.

Router Table: Offers increased control since both hands are available to guide the workpiece. Accessories like featherboards help prevent kickback and ensure safer operation.

Conclusion

Ultimately, the choice between a spindle shaper and a router table depends on your specific woodworking needs and project types. If you primarily focus on larger projects requiring deep cuts and specialized profiles, investing in a spindle shaper may be worthwhile. However, if versatility and ease of use are your priorities—especially for smaller projects—a router table could be the better option.

By understanding the strengths and limitations of each tool, you can make an informed decision that enhances your woodworking experience and leads to high-quality results in your projects. Whichever tool you choose, mastering its use will undoubtedly elevate your craftsmanship in woodworking.