How to maintain the wood vertical band saw machine

1. The saw wheel bearing is an important rolling part of the band saw machine, and its work, lubrication and wear should be checked frequently. Under normal working conditions, check and compensate the amount of grease once a week. If the grease is found to be discolored or have impurities, replace it in time. When compensating the amount of grease, it should not be too much, generally 65% of the entire bearing space is appropriate, and the grease change time should not exceed 3 months. ZL-1 general-purpose lithium-based grease is used for the grease. When changing the grease, the bearings, bearing connections and grease should be kept clean.

2. Screw transmission parts, gear transmission parts, and sliding guide parts should be filled with mechanical lubricant once every shift, and wood chips and dust should be often eradicated at the same time.

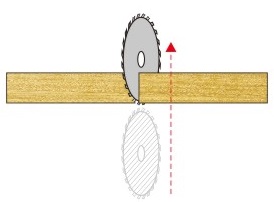

3. Frequently check the wear of the saw wheel and saw blade, and trim it in time.

4. In particularly severe cold areas, antifreeze lubricating grease should be used.

5. Always check whether the fasteners are loose and clean them in time.

6. When the machine tool is out of service, the movable parts and the exposed processing surface should be coated with oil to prevent

2. Screw transmission parts, gear transmission parts, and sliding guide parts should be filled with mechanical lubricant once every shift, and wood chips and dust should be often eradicated at the same time.

3. Frequently check the wear of the saw wheel and saw blade, and trim it in time.

4. In particularly severe cold areas, antifreeze lubricating grease should be used.

5. Always check whether the fasteners are loose and clean them in time.

6. When the machine tool is out of service, the movable parts and the exposed processing surface should be coated with oil to prevent