How To Choose A Wood Laminating Machine For Woodworking?

Selecting the right wood laminating machine is a critical decision for any woodworking project, whether you're a hobbyist or a professional. The right machine not only enhances productivity but also improves the quality of your finished products while minimizing waste. This guide will provide a comprehensive overview of the factors to consider when choosing a wood laminating machine, ensuring you make an informed decision that meets your specific needs.

Understanding Wood Laminating Machines

Wood laminating machines are specialized tools designed to apply a layer of laminate to wood surfaces. This process serves multiple purposes, including enhancing durability, improving aesthetics, and adding functionality to wood products. The market offers various types of laminating machines, each with unique features and capabilities. Understanding these differences is essential for selecting the best machine for your projects.

Types of Wood Laminating Machines

When exploring wood laminating machines, you'll encounter several types, each suited for different applications:

Roll Laminators: These machines are ideal for high-volume production environments. They utilize large rolls of laminate film to cover surfaces quickly and efficiently, making them perfect for businesses that require consistent output.

Pouch Laminators: Best suited for smaller projects or home workshops, pouch laminators use pre-sized pouches that encase the material being laminated. They are generally more user-friendly and affordable.

Cold Laminators: These machines apply adhesive without heat, making them suitable for sensitive materials that could be damaged by high temperatures. Cold laminators are often used for graphics and signage.

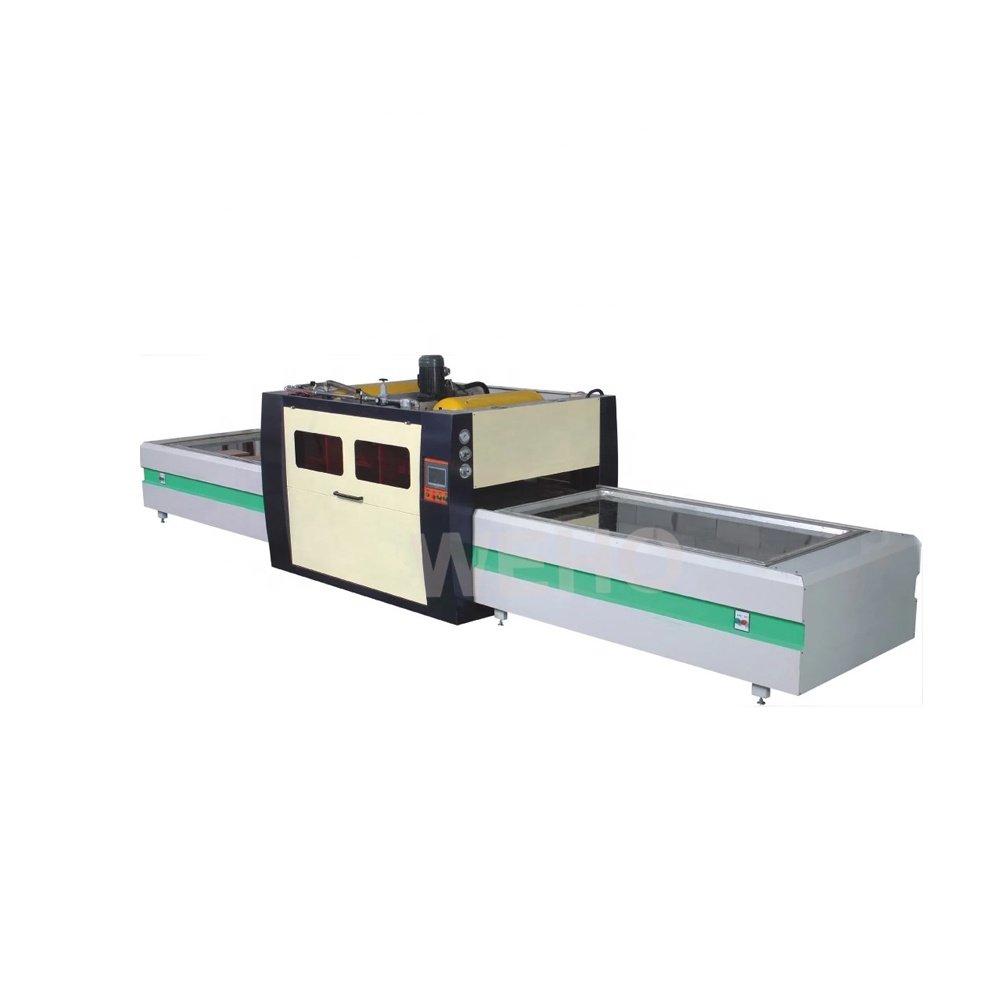

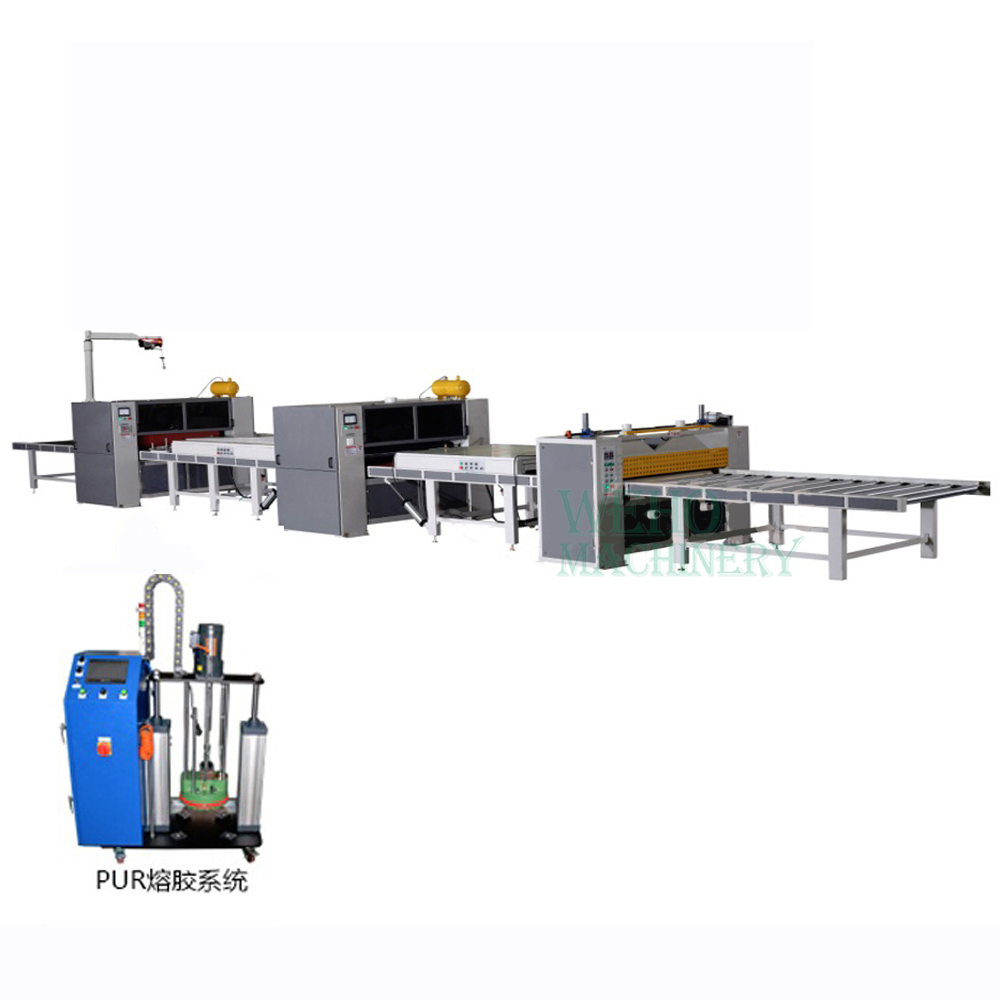

Hot Melt Laminators: Utilizing heat to activate adhesive on laminate film, hot melt laminators provide a strong bond suitable for various substrates. They are commonly used in furniture manufacturing and cabinetry.

Key Factors to Consider When Choosing a Wood Laminating Machine

Choosing the right wood laminating machine involves evaluating several key factors that will impact your projects:

1. Machine Size and Capacity

The size of the machine is crucial based on your workspace and the scale of your projects. Small machines are ideal for home workshops or small businesses due to their compact design. However, they may have limitations regarding material size and production volume. In contrast, larger machines cater to industrial applications, handling wider materials and higher volumes but requiring more space and investment.

2. Speed and Efficiency

Operational speeds significantly affects productivity. High-speed machines are essential for businesses with heavy workloads as they can drastically reduce turnaround times. Additionally, machines with adjustable speed settings allow you to tailor operations according to project requirements, balancing speed with quality.

3. Precision and Control

Precision is vital for achieving high-quality lamination results. Modern machines often feature digital controls that allow precise adjustments of temperature, pressure, and speed. Some advanced models come equipped with automatic sensors that detect material thickness and adjust settings accordingly, ensuring optimal results.

4. Safety Features

Safety should never be compromised in woodworking operations. Look for machines equipped with emergency shut-off mechanisms to protect users during operation. Heat shields are also beneficial in preventing burns and accidents when working with hot melt laminators.

5. Versatility

A versatile laminating machine can accommodate various types of laminate films and substrates. Machines that work with glossy, matte, or textured laminates expand your application range and enhance creativity in your projects.

6. Maintenance Requirements

Regular maintenance is crucial for the longevity of any machinery. Choose machines designed for easy cleaning to minimize downtime due to maintenance issues. Adhering to manufacturer guidelines for routine maintenance will help ensure optimal performance over time.

Evaluating Your Needs

Before making a purchase, it's essential to evaluate your specific needs:

- Project Volume: Determine how many projects you plan to complete within a given timeframe. This assessment will help you decide whether you need a high capacity machine or if a smaller model suffices.

- Material Types: Identify the types of materials you will frequently work with. Different machines may perform better with specific substrates, so choose one that aligns with your primary materials.

Budget Considerations

Your budget will significantly influence your choice of laminating machine:

Initial Investment vs. Long-Term Savings: While it may be tempting to opt for cheaper models, investing in a reliable machine can lead to savings in maintenance costs and operational efficiency over time.

Cost of Consumables: Factor in the cost of laminate films or adhesives required for operation when budgeting for your machine.

Conclusion

Choosing the right wood laminating machine is essential for enhancing efficiency and quality in your woodworking projects. By carefully considering factors such as size, speed, precision, safety features, versatility, maintenance needs, and budget constraints, you can make an informed decision that aligns with your woodworking goals.

For those looking for high-quality wood laminating solutions, consider WEHO as your trusted partner in woodworking machinery. WEHO offers a range of advanced wood laminating machines designed to meet diverse needs while ensuring reliability and performance in every project. Investing in WEHO equipment means investing in quality that lasts—enhancing both your craftsmanship and productivity in the woodworking industry.