CNC woodworking panel saw No manual cutting required Safe and precise

In recent years, with the rapid development of the furniture industry, the old-fashioned woodworking panel saws represented by push table saws have poor precision, low efficiency, easy failure, and many work injuries, which cannot meet the needs of enterprises to pursue efficient and accurate processing. Seriously hinder the progress of enterprises. The birth of CNC panel saw effectively avoids such problems.

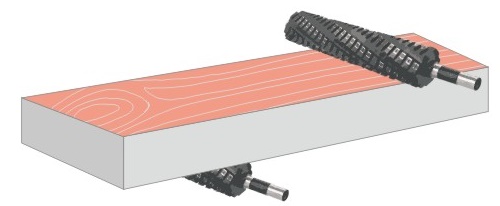

CNC panel saw, also known as CNC vertical and horizontal panel saw, CNC reciprocating saw, CNC woodworking saw, woodworking panel saw, it integrates the functions of cutting machine and electronic panel saw. It is a high-definition touch screen control , Automated woodworking cutting machinery with man-machine integrated operation. In the entire workflow, only manual loading and unloading is required, and the vertical and horizontal cutting process is fully automated.

The CNC vertical and horizontal panel saw can cut vertically and horizontally in both directions. It is equipped with a feeding manipulator for automatic clamping and one-time positioning of feeding, and an auxiliary pressing device, which can effectively ensure that the wood will not shift during the working process of the machine. It avoids the inconsistency of the precision of the wood caused by adjusting the position of the board during the manual cutting process. The high-precision servo system controls the feeding accuracy, the electronic ruler positioning compensation, and the linear precision guide rail, which is convenient for sheet conveying and greatly improves the work efficiency. The cutting accuracy is ±0.02mm, far exceeding the standard required by furniture production.

When the CNC vertical and horizontal panel saw is working, the saw head rotates, and the saw blade is enclosed by the protective cover, which prevents work accidents and avoids dust splashing everywhere when cutting wood. The mechanical platform is equipped with a vacuum adsorption device. The dust removal port is connected to our dust removal equipment, and the dust can be handled well. This dust removal device can ensure the working accuracy, improve the service life and reduce the mechanical failure rate.

CNC panel saw, also known as CNC vertical and horizontal panel saw, CNC reciprocating saw, CNC woodworking saw, woodworking panel saw, it integrates the functions of cutting machine and electronic panel saw. It is a high-definition touch screen control , Automated woodworking cutting machinery with man-machine integrated operation. In the entire workflow, only manual loading and unloading is required, and the vertical and horizontal cutting process is fully automated.

The CNC vertical and horizontal panel saw can cut vertically and horizontally in both directions. It is equipped with a feeding manipulator for automatic clamping and one-time positioning of feeding, and an auxiliary pressing device, which can effectively ensure that the wood will not shift during the working process of the machine. It avoids the inconsistency of the precision of the wood caused by adjusting the position of the board during the manual cutting process. The high-precision servo system controls the feeding accuracy, the electronic ruler positioning compensation, and the linear precision guide rail, which is convenient for sheet conveying and greatly improves the work efficiency. The cutting accuracy is ±0.02mm, far exceeding the standard required by furniture production.

When the CNC vertical and horizontal panel saw is working, the saw head rotates, and the saw blade is enclosed by the protective cover, which prevents work accidents and avoids dust splashing everywhere when cutting wood. The mechanical platform is equipped with a vacuum adsorption device. The dust removal port is connected to our dust removal equipment, and the dust can be handled well. This dust removal device can ensure the working accuracy, improve the service life and reduce the mechanical failure rate.