CNC Tenoner Vs Traditional Tenoning Machines: Which Is Better?

The woodworking industry thrives on precision, efficiency, and innovation. Among the critical tools shaping this field, tenoning machines stand out for their role in crafting durable joints for furniture, cabinetry, and architectural elements. As technology advances, CNC tenoners have emerged as a transformative upgrade over traditional tenoning machines. This article explores the advantages of CNC tenoners and why they are increasingly becoming the preferred choice for modern workshops. By the end, you'll also discover why WEHO, a leader in CNC machinery, should be your go-to partner for upgrading your woodworking capabilities.

Why CNC Tenoners Outperform Traditional Machines

1. Unmatched Precision and Consistency

CNC tenoners deliver sub-millimeter accuracy in every cut, thanks to computer-controlled servo motors and advanced calibration systems. Unlike traditional machines, which rely on manual adjustments and operator skill, CNC systems execute pre-programmed designs flawlessly. This eliminates human error and ensures perfectly uniform tenons across large production runs. For industries like high-end furniture manufacturing or architectural millwork, where precision is non-negotiable, CNC tenoners are indispensable.

2. Versatility in Design and Application

Traditional tenoning machines are limited to cutting straight or square tenons. In contrast, CNC tenoners can produce complex shapes, including angled, rounded, or custom-profile tenons, with a simple software adjustment. This flexibility allows woodworkers to experiment with innovative joinery techniques, cater to bespoke client requests, and tackle projects that were previously impractical. Whether you're crafting curved chair legs or intricate door frames, CNC technology adapts effortlessly.

3. Enhanced Production Efficiency

CNC tenoners excel in high-volume production environments. Once the design is programmed, the machine operates autonomously, requiring minimal supervision. This automation reduces labor costs and accelerates throughput, enabling workshops to meet tight deadlines without compromising quality. Traditional machines, while effective for small batches, struggle to match the speed and scalability of CNC systems, especially for complex or variable tasks.

4. Material and Cost Savings

By optimizing cutting paths and minimizing errors, CNC tenoners reduce material waste significantly. Traditional methods often result in scrap due to manual misalignments or trial-and-error adjustments. CNC systems calculate the most efficient use of raw materials, lowering costs and supporting sustainable practices—a critical advantage in today's eco-conscious market.

5. Improved Safety for Operators

CNC tenoners prioritize operator safety through automated processes and enclosed cutting zones. Workers interact with the machine via a user-friendly interface, avoiding direct contact with blades during operation. Traditional tenoning machines, which involve manual feeding and blade adjustments, pose higher risks of accidents, especially during long shifts or repetitive tasks.

6. Seamless Integration with Digital Workflows

Modern CNC tenoners integrate with CAD/CAM software, allowing designers to translate digital blueprints directly into machine instructions. This end-to-end digital workflow eliminates translation errors and speeds up prototyping. For example, a furniture designer can create a 3D model in software like AutoCAD, generate toolpaths, and send the file to the CNC tenoner—all without manual measurements or setup.

7. Scalability for Future Growth

Investing in a CNC tenoner future-proofs your workshop. As demand grows, these machines can scale production effortlessly by replicating designs or adjusting parameters. Traditional machines, while reliable for static tasks, lack the adaptability needed to pivot toward new markets or product lines. CNC systems also receive software updates, ensuring compatibility with evolving industry standards.

Industries Benefiting from CNC Tenoners

Furniture Manufacturing: Perfect for mass-producing chairs, tables, and cabinets with intricate joinery.

Door and Window Production: Ensures precise mortise-and-tenon joints for energy-efficient frames.

Musical Instrument Crafting: Creates delicate joints for guitars, pianos, and violins.

Custom Woodworking Studios: Empowers artisans to execute one-of-a-kind designs efficiently.

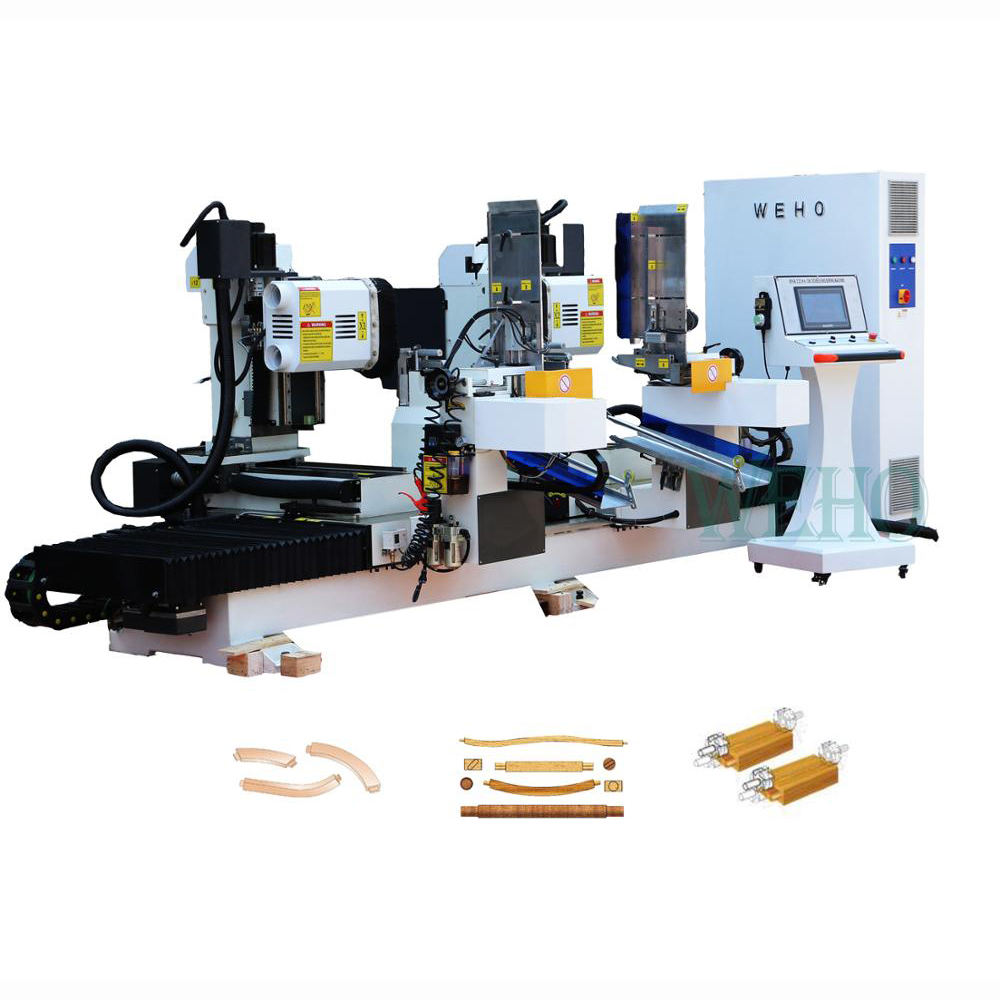

Why Choose WEHO for Your CNC Tenoner Needs?

At WEHO, we specialize in delivering high-performance CNC tenoners tailored to your workshop's unique requirements. Here's why industry leaders trust us:

Cutting-Edge Technology: Our machines feature the latest servo motors, touchscreen interfaces, and collision-detection systems.

Custom Solutions: Whether you need a compact model for a small shop or an industrial-grade system, we design machines to match your workflow.

Lifetime Support: From installation to software updates, our technical team ensures your CNC tenoner operates flawlessly for years.

Sustainability Focus: Our energy-efficient designs help reduce your carbon footprint while lowering operational costs.

Ready to elevate your woodworking capabilities? Visit WEHO's official website to explore our CNC tenoner lineup or schedule a consultation with our experts today.

Conclusion

The evolution from traditional tenoning machines to CNC systems represents a paradigm shift in woodworking. With superior precision, versatility, and efficiency, CNC tenoners empower workshops to tackle complex projects, reduce waste, and scale production effortlessly. While traditional machines still have a role in niche applications, the future undeniably belongs to CNC technology.

For businesses aiming to stay competitive, investing in a CNC tenoner is not just an upgrade—it's a strategic move toward sustainable growth. And when it comes to reliability and innovation, WEHO stands as your ideal partner, offering state-of-the-art machinery backed by unparalleled expertise.

Upgrade your workshop with WEHO's CNC tenoners and redefine what's possible in woodworking.