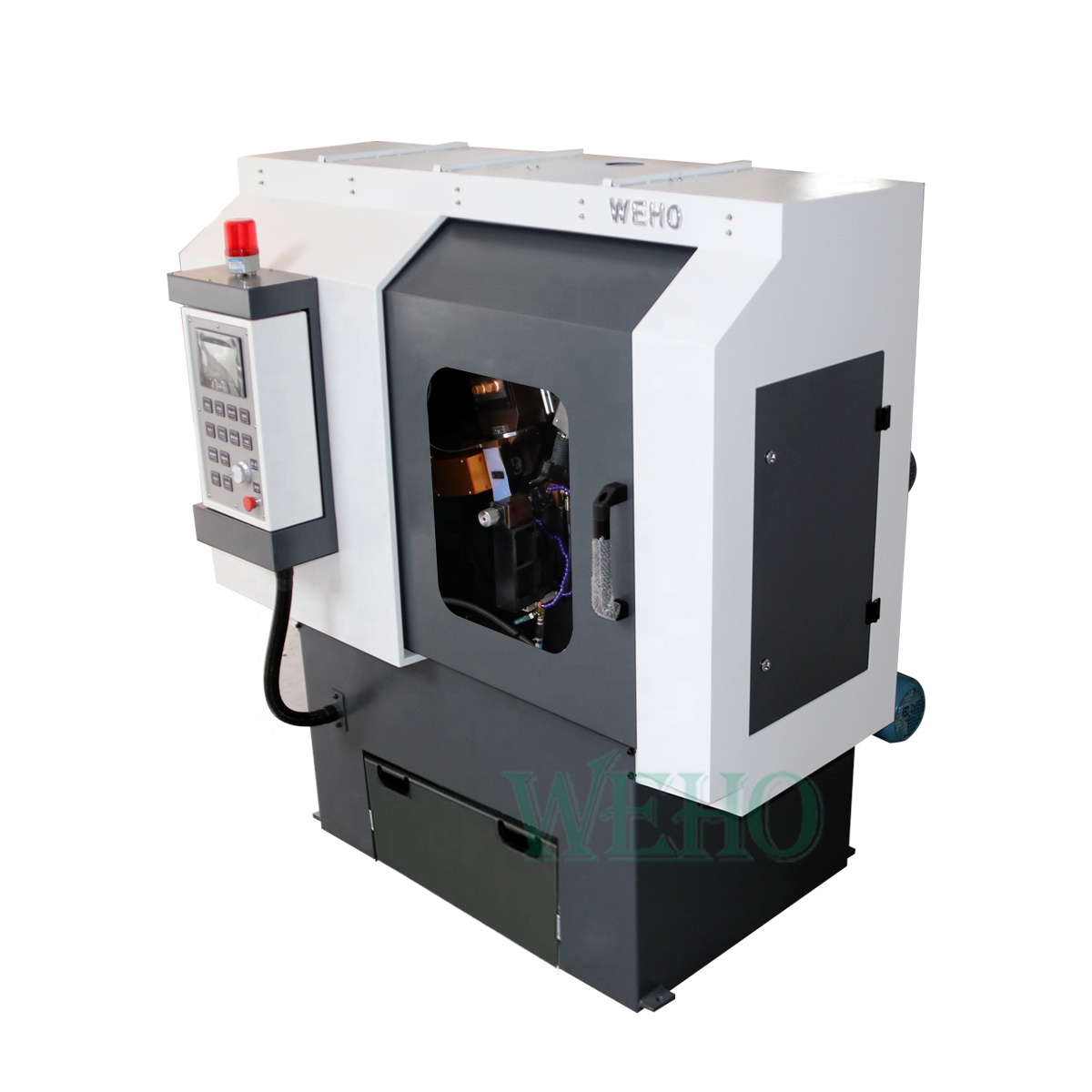

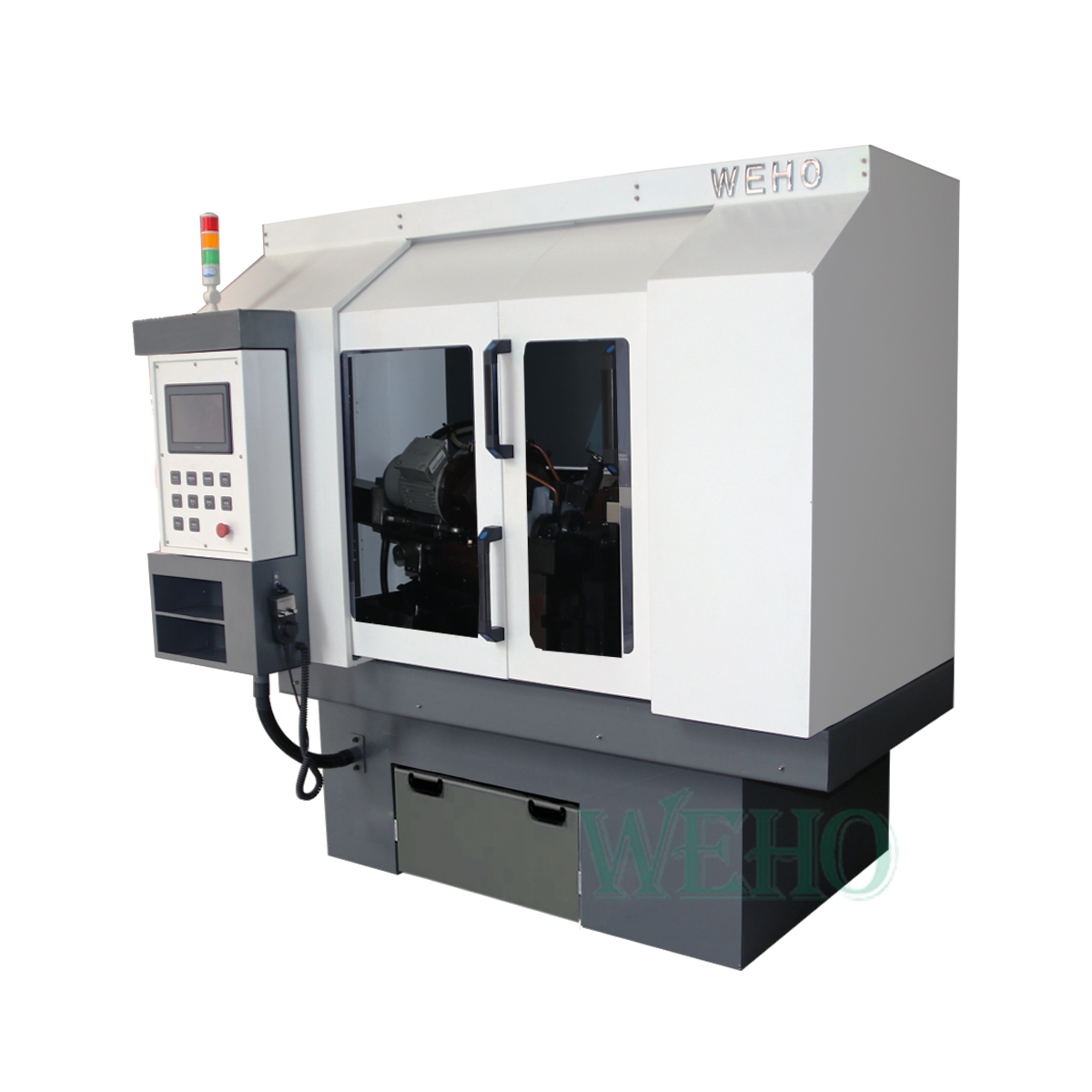

The Benefits of Using a TCT Saw Blade Grinding Machine

Tungsten Carbide Tipped (TCT) saw blades are widely used in woodworking, metalworking, and other industries for their durability and cutting performance. However, even the highest quality TCT saw blades will eventually become dull with use. Investing in a TCT saw blade grinding machine offers a multitude of benefits, extending the life of your blades, improving cutting quality, enhancing safety, and ultimately saving you money. This article explores the various advantages of using a TCT saw blade grinding machine, demonstrating why it is a crucial investment for both professionals and hobbyists alike.

Cost-Effectiveness

One of the most compelling reasons to invest in a TCT saw blade grinding machine is the significant cost savings it provides. Regularly replacing saw blades can become an expensive undertaking, especially when using high-quality TCT blades. Sharpening your existing blades allows you to extend their lifespan, reducing the frequency of replacements and saving you money in the long run.

Reduced Replacement Costs: Purchasing new saw blades, particularly high-quality models, can be a substantial expense. A TCT grinding machine allows you to maintain your current blades, significantly prolonging their usability and saving on replacement costs.

Affordable Maintenance: The cost of sharpening a saw blade is considerably less than buying a new one. Professional sharpening services charge a fraction of the price of a new blade, making it a financially sound decision to invest in a grinding machine for in-house maintenance.

Enhanced Cutting Performance

A sharp blade is essential for achieving optimal cutting performance. TCT saw blade grinding machines ensure your blades are always in top condition, providing a variety of benefits:

Smoother Cuts: Sharp blades produce cleaner and smoother cuts, which are essential for high-quality work. Dull blades tend to tear or splinter materials, leading to rough edges and increased material waste.

Increased Precision: Sharpening restores the blade's cutting edge, allowing for more accurate cuts. This precision is particularly important in detailed woodworking or when working with fine materials. A TCT saw blade grinding machine with CNC capabilities can achieve exacting angles and profiles, ensuring consistent and precise cutting performance.

Optimum Saw Productivity: Maintaining your TCT saw blades with a grinding machine will lead to high cutting output and improved cutting quality, contributing to greater productivity.

Improved Safety

Using sharp blades is not only more efficient but also significantly enhances safety during cutting operations.

Reduced Risk of Accidents: Dull blades require more force to cut through materials, increasing the likelihood of slips and accidents. A sharp blade cuts more efficiently and requires less effort, reducing the risk of injury.

Better Control: Sharp blades provide better control during cutting operations. This control helps prevent kickbacks and other dangerous situations that can arise from using dull or improperly maintained tools.

Overall Safety: Sharpening saw blades enhances performance, safety, and the overall quality of work.

Increased Efficiency

In any trade, time is a valuable asset, and using a TCT saw blade grinding machine can significantly improve efficiency.

Faster Cutting: Sharp blades cut through materials more quickly than dull ones. This speed saves time and allows more projects to be completed in a shorter timeframe.

Less Downtime: Regularly sharpening blades reduces the frequency of replacements and repairs, leading to less downtime in your workflow. This efficiency is particularly beneficial for professionals working on tight schedules.

Quick Adjustments: Certain TCT saw blade grinding machines offer quick adjustment features for chamfering and simple menu-driven programming with the memory of complete programs, saving you time and effort.

Environmental Benefits

Choosing to sharpen blades instead of replacing them contributes to environmental sustainability.

Reduced Waste: By extending the life of your saw blades through sharpening, you contribute to less waste in landfills. This practice aligns with sustainable working practices that prioritize resource conservation.

Lower Resource Consumption: Manufacturing new saw blades consumes resources and energy. By reusing and maintaining existing tools, you help minimize the environmental impact associated with production processes.

Versatility

TCT saw blade grinding machines are versatile tools that can accommodate various types of blades.

Multiple Blade Types: Many sharpeners are designed to handle different types of saw blades, including circular saws, band saws, and miter saws. This versatility makes them a valuable addition to any workshop. Some machines can process both carbide-tipped (TCT) saw blades and HSS saw blades.

Adjustable Settings: High-quality sharpeners often come with adjustable settings that allow users to customize the sharpening angle and depth based on specific blade requirements. Some machines feature automatic adjustment systems where the grinding wheels adjust position automatically.

Various Applications: A TCT saw blade grinding machine is suitable for grinding carbide-tipped wood cutting saw blades, aluminum cutting saw blades, and forest saw blades.

Skill Development

Using a TCT saw blade grinding machine can enhance your skills as a craftsman.

Understanding Tool Maintenance: Learning how to sharpen your own blades fosters a deeper understanding of tool maintenance and care. This knowledge can lead to better overall craftsmanship and tool longevity.

Improved Technique: Regular sharpening practice helps develop better techniques for using tools effectively and safely, ultimately improving your overall skill set as a woodworker or metalworker.

Advanced Features and Automation

Modern TCT saw blade grinding machines come equipped with advanced features that further enhance their benefits.

CNC Technology: CNC grinding machines offer precise control over the sharpening process, ensuring consistent and accurate results.

Automatic Adjustment Systems: Some machines feature automatic adjustment systems, where the grinding wheels automatically adjust their position for optimal sharpening.

User-Friendly Interfaces: Many machines have user-friendly touchscreen controls with intuitive symbols that guide the operator through the sharpening process.

Cooling Systems: Advanced cooling systems, like neat oil cooling systems, extend the lifespan of the machine and grinding wheel.

Precision and Durability: Features such as special-made forging main spindles, Germany ABB motors, and the absence of pneumatic or hydraulic systems ensure high precision and long-term durability.

Conclusion

Investing in a TCT saw blade grinding machine offers numerous advantages that enhance both the quality of work and safety in various trades. From cost savings and improved cutting performance to environmental benefits and skill development, a grinding machine is a wise decision for anyone serious about their craft. By maintaining sharp blades, you not only ensure better results but also contribute positively to your workflow efficiency and sustainability efforts. Investing in quality sharpening equipment or services will pay off in the long run, ensuring that your tools remain effective and your projects are executed with precision and care.